Traxxas offer several versions of the high performance Traxxas Slash 1/10 SCT (short course truck). While there are various levels of electric 2WD and 4WD (as well as a nitro version), selecting a great servo for this rig is actually pretty easy because they all take a standard-class servo (basically means a 20x40mm footprint).

Thing is, everybody and their brother has a different opinion regarding the best servo for anything. Even Traxxas get into the act with upgrade-servos (and if we're being honest, some pretty good ones, too). But with so much noise about servo features, it's really easy to get overwhelmed wrapped around the axle with what's actually important for you.

Our approach will be to help you figure out what the benefits are. How? By teaching you what's in it for *you* by discussing the features the servo vendors yap about in servo-world.

So instead of jumping in with *our* recommendations (and risk confusing you further), the goal of this guide is instead, to help you cut through the bullshit suss out which servo features actually have *benefits* important for your situation, and *your* budget. And yes, of course we'll make a recommendation, but not until you actually have a clue regarding what all the blah-blah is about.

After all, if there were such a thing as a one-size-fits-all servo-wise, then we wouldn't have 12 standard size servos that'll fit this rig! Anyway, regarding *how* we'll get you there, it's by showing you what makes up a servo . . . what the fundamental parts are.

Along the way we'll explain some pros and cons. We'll use some servos Traxxas offer, a few other competing servos, plus our own servos to explain. But remember, it's just a servo so unless you're terminally stupid, you'll quickly figure it's actually not all that hard to grok. You just need someone to explain it. That's us. And you? Your job is keeping an eye on where *your* interest lie. Like if I explain a benefit and you don't think it's important for you, then that's the answer, that particular benefit doesn't ring your bell. So instead of getting bogged down, learn about the next benefit and so on.

Best part? By the end of this guide you'll never again need *anybody*, not us or anybody else to tell you what to do when it comes to selecting a servo. You'll be able to decisively act in your own best interests (with the side benefit of forever more discerning who dispenses good advice and who is full of shit).

Bottom line? There's no one answer to, 'What's the best servo? It will always depend. On what? You, and your needs! And trust us in this, if nothing else, making a good decision about your next servo isn't rocket science!

On the bits and bobs of a servo - or parts are parts - until they're not!

A servo is made up of 7 fundamental parts. These include . . .

- the case

- the bolts holding it together

- o-rings for sealing out bad stuff

- the gear train

- motor

- potentiometer

- and the PCB (upon which are soldered teeny-tiny electronic components)

And note, there's more than just seven parts, but these 7 stand in for all the various components. And just as once you've heard the difference, there's zero chance of confusing the sound of a Mercedes driver's door slamming shut versus a Kia, with servos it's always down to the quality of the individual parts to help you figure out what the good stuff is vs low-bidder.

After all, the sum of the parts is more than the whole. Saying if the individual parts are better, then the whole darn servo is better, too. And as you gain experience with hos the world works you'll realize this is a life lesson . . . meaning it's true for any and every product in the world regardless of whether it's a servo, luxury car, or refrigerator!

Difference between rookie purchasers and pros

OK, wanna know how a rookie buys a servo? He decides based on price, torque, and speed. That's it, and usually in that order. An experienced modeler? He looks deeper into the actual component parts. Sure price, torque, and speed play a role - but - for a pro, they're not the only important things.

I'll begin by using four well known Traxxas products to illustrate; the stock 2075, and the metal gear upgrade version, the 2075X. Both output 125oz-in at 6V and transit in 0.17sec/60°, and we'll also eyeball the 2050 (High-Torque 330 Blue) and 2055 (High-Torque 400 Blue), plus known good competitors like the famous Savox SB-2290SG Monster every hobby dealer on earth trades in.

And before we get down to it, allow me to encourage you to take 2-minutes and review what Traxxas has to say about selecting servos. It's good stuff, believe me;

- Traxxas: Everything you need to know about servos

And note, feel free to click the link. Like every link in a caseSTUDY, it opens in a new browser tab. Means you won't lose your place in *this* article. So go ahead and click the Traxxas link.

Welcome back! You saw how Traxxas concisely discussed several subjects to include what's inside a servo, as well as specs like torque, speed, and voltage, plus they touched on gears (metal better than plastic), and a paragraph regarding types of motors (brushed and brushless), as well as a little propaganda about 2075X, 2075R, High-Torque 330 Blue, and High-Torque 400 Red servos, plus they touched on three sizes of servos (standard, micro, and sub-micro).

Like I said, good stuff. Maybe a bit basic but nevertheless, recommended reading because it gives you a foundation so we don't have to! So now it's our turn to teach to a greater depth.

1. Servo case - the component parts holding everything together

A servo case, the parts, are made up of three sections. The center case, the upper housing for the transmission, and the lower electronics cover. The well known Traxxas 2075 ($40) and 2075X/2075R ($50) use an engineering polymer (plastic) for all three sections. Good thing about plastic is it's cheap, and reasonably strong. Some servos have four case-components instead of three, ProModeler does and it's because you get an alloy case instead of plastic.

- ProModeler on the left, a Hitec product on the right, 4 vs 3 case bits, doesn't matter

Enter the ProModeler DS270DLHV and DS360DLHV into the discussion. Priced at $45 and $50 respectively, these servos also use engineering polymer case sections (plastic). But it's only used for the upper transmission section and electronic cover, just like Traxxas (and for the same reason, cost).

Strong and impact resistant, ours (and we suspect Traxxas, as well) use a special plastic, technically an engineering polymer called Nylon 6.6 (which is also the same kind of fiber-filled polymer used in a Glock handgun side frame). Pretty impact resistant stuff to withstand the abuse of thousands upon thousands of rounds, right? Ditto when used in servos. Good stuff.

- Like well made Traxxas units with plastic tops, ProModeler bronze-reinforce gear shaft bores

Continuing with plastic, along with the good, there's the bad. Bad thing about plastic is it's a thermal insulator. So where this becomes a problem for *you* is servo motors get hot, and because heat is the enemy of electronics, then plastic is a less than desirable material in this regard.

So now we're specifically focusing on using plastic for the center case, where we don't think it's a good idea because it doesn't help the motor shed heat (heat being that which reduces the lifespan of the electronics components). Why? Because plastic a thermal insulator, it's holding the freaking heat inside the servo, is why! This is not good.

Note; the higher performance the servo, the more heat is retained because the servo is working harder when it's outputting more torque (we'll explain in more

detail later but it comes down to current-use).

Basically, just like a 100W bulb makes a brighter light than a 50W bulb, the same holds for a servo and the higher the wattage, the more torque it produces. And all else being equal, this means more heat. Remember, for electronics, heat is bad juju!

Point being, a servo consumes more electricity making 500oz-in than 250oz-in (just about double, in fact), which makes perfect sense. And all this comes down to this simple formula;

. . . in English, this means at a given voltage, say 6V or 7.4V, if you multiply the voltage (V) by the current (A), then you get Watts (W).

As a practical matter, a 3A servo at 6V is an 18W device (because 3x6=18). And 18W is a lot of concentrated heat. Note; I didn't pluck 3A out of the air, that's a common number in ESC output via the BEC in consumer grade RTR-electronics. More later.

Meanwhile, think back . . . ever touch a 5W Christmas tree bulb or a 15W refrigerator bulb? Burned the crap out of you, right? Well, 5W is a *lot* less than 18W so a servo shedding 18W has to do it *somehow* or it stays inside the servo thereby reducing the lifespan of your expensive servo electronics. Plastic center cases? They ain't good!

Heat is bad juju for electronics!

Gets worse, too, because we have some 85W servos in the lineup and 60-80W is pretty common in top performing servos! So using middle school Algebra, where W=VxA can be solved for A by dividing by V, so W=VxA can be rearranged as W/V=A by dividing both sides by A. Then just plugging in the numbers works out to 85W/8.4V=10.1A of current, and 10A becomes important later. Basically, there's a damned good *reason* so many aftermarket BEC claim 10A of output. It's to deal with top end servos!

Bottom line? Servos have to shed heat. And the harder they work (e.g. the higher the performance), then the more heat they have to shed. This isn't opinion, it's physics!

Of course, Traxxas knows this, which is why more expensive servos like 2250 (High-Torque Blue) and 2255 (High-Torque Red) have an aluminum center case section. Aluminum sheds heat better. Problem now is, instead of $40-50 for a 2075 or 2075X servo, we're talking $80-100 for a servo.

Which brings us back to the ProModeler DS270DLHV and DS360DLHV ($45 and $50 respectively). Reason I bring them up is that in common with 100% of the ProModeler servo line up, the center case, the one housing the motor (the component that gets hot when the servo is working hard) is never made of plastic. It is always made of aluminum. Remember, sheds heat better!

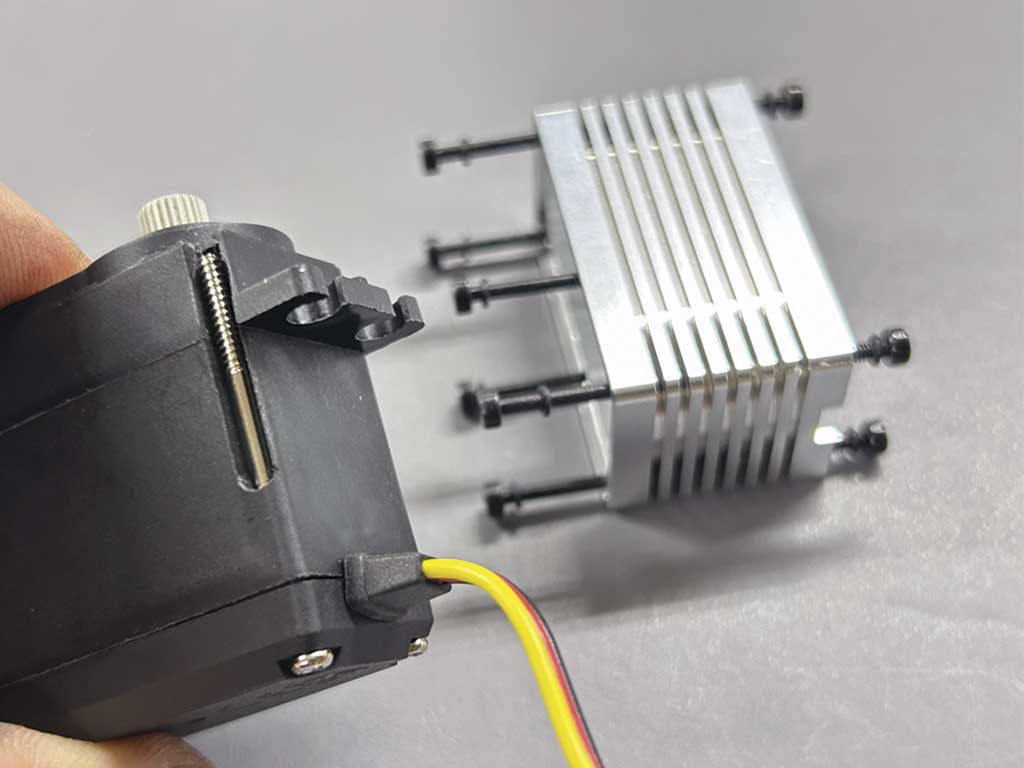

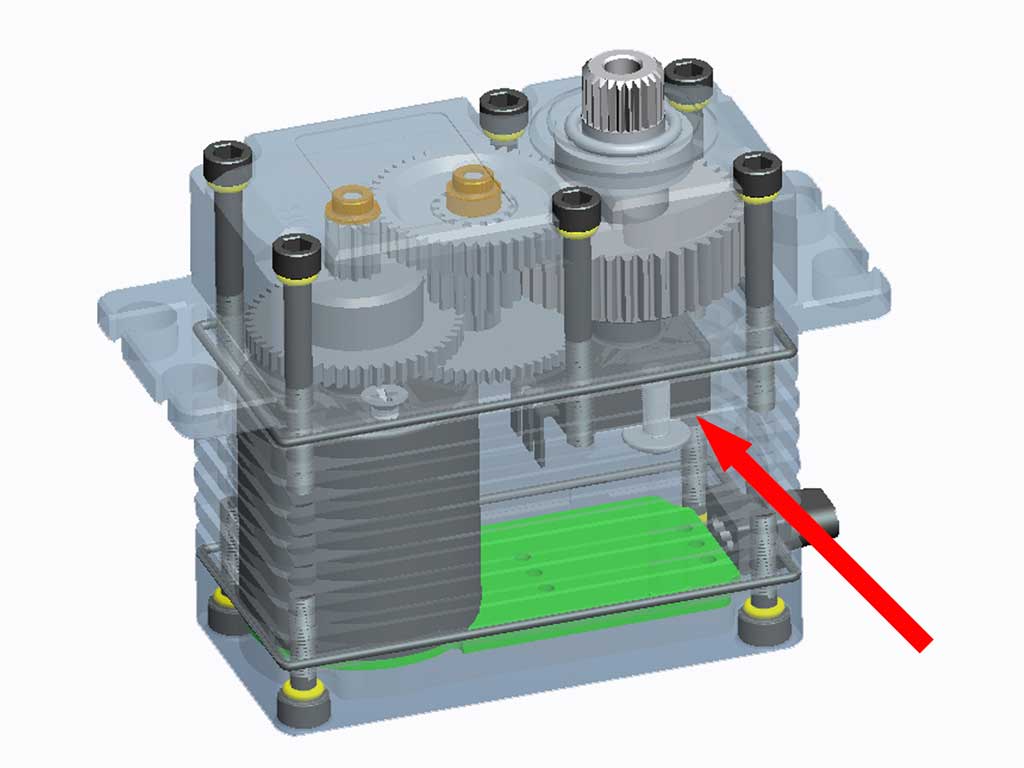

Minor point is, if you recall this whole discussion relates back to better parts, right? Then prepare to get your mind blown. Meet what the design team calls the porcupine . . .

- Internally, referred to as the porcupine because of the 10-bolts sticking out like quills

More importantly, it's not just that the porcupine is made of aluminum, it's aluminum which we CNC-machine out of a solid billet of 6061-T6 aircraft aluminum. And note the cooling fins.

Cooling fins are important because they shed heat better.

As for how much better cooling fins shed heat versus a servo where the aluminum center is smooth as a baby's bottom? This is expressed in another formula where fin efficiency is calculated for a constant heat transfer coefficient based on the fin area, using this formula

- ? = T ¯ f i n - T c z T b - T c z

. . . and no, I won't run you through this bit of math!

Just know this about it, just like motorcycle engines have cooling fins, and CPU-coolers in computers have them, serious performance servos have them, too. ProModeler servos? Serious performance, even if you're only spending $30 with us.

Look, it's your money, you'd rather a servo with a plastic case, that's your lookout. We're just educating you about what's what in servo world. Aluminum center gives you cooler electronics. Put another way, mo' betta!

Time is money

So here's why everybody doesn't do alloy fins centers. It's because machining these cooling fins is expensive to do. The fins *alone* basically double the milling time within the machine-cell. It adds up, too because this means the man tending the mill also waits twice as long for the machine to complete the cycle for that operation (so labor cost doubles, electricity consumption doubles, production from that machine is 1/2, etc.). So why does ProModeler do it? Simple, because engineers make engineering-decisions at ProModeler, not marketing types (in fact, they don't actually get a say). So if you want servos where marketing types make the decisions, then ProModeler servos aren't for you. No offense.

And note; when marketing types *force* engineers to save money, they can. Comes at the cost of performance, of course. Examples include servos which extrude an aluminum center instead of machining it . . . just like squeezing Play-Doh through the star shape, remember that? And the tip-off they're doing this (presuming you're not an engineer or machinist) is surprisingly easy to spot. You just need a set of Eyeballs Mk II.

How? The four bolts securing the three case sections together are typically 4-long ass cheese cutters going through the bottom cover (electronics), then they pass clean through the center case (plastic, or aluminum, doesn't matter) and only thread into the plastic top (transmission case).

Note; they're called cheese cutters because of their coarse-threads, which are self-tapping into the plastic. Typically with el cheapo Phillips head screws . . . looking something like this.

- A seriously inexpensively designed product uses 4 cheese-cutters to assemble the case

So let's take a moment before we move on. Scroll back up and eyeball the porcupine one last time. Note how more than just cooling fins, that rascal has been drilled and tapped 10X for M2 machine-thread Grade 12.9 Allen head bolts. The extruded case has the holes already, they just slice it to length. A fully machined case like ProModeler? Takes way more times to drill and tap the case in 10 places. Makes for a more securely anchored assembly.

Tapped alloy mounting points are the good stuff! And this brings us to yet more servo parts! And the reason the center case is tapped in the first place.

2. The bolts holding it together

We all know the difference between Allen head and Phillips head, right? The grade 12.9 bolts used by ProModeler won't round out. Phillips head? Most modelers hate them. For good reason.

And just like that, we're back to the sound of a Mercedes driver's side door slamming, quality can be easily discerned just by the sound. It's because of the fine quality that's engineered into into the vehicle. And it doesn't happen by accident. Each individual component part is selected to be the best. A ProModeler servo is pretty much the same.

So let's look at the little M2 bolts securing the bottom cover. Tiny things. Could ProModeler have used Phillips head screws instead of Allen head bolts and saved money? Yes, of course. What's more, most customers wouldn't know the difference - or care. But savvy buyers, pros? They know the difference 100% yet plenty of folks are out there buying servos with Phillips screws, right? Is it because they have no choice r because they haven't twigged to this small detail one of those tells a poker player uses to know something about an opposing player's hand?

Remember, rookies they buy servos based on price, torque, and speed . . . in that order. And some like shiny things the way a bass is attracted to shiny spinner bait. More later. Meanwhile, a pro looks at everything and the little tells like Allen head vs Phillis head help inform him about who he is doing business with. It all adds up!

The guide's about bringing you up to speed so nobody can fool you with regard to servos. The fasteners aren't a big deal, they're a small touch but bear it in mind because if someone pays attention to the smallest detail it's reasonable to suspect they mind the store with the big stuff, too. Put another way, details count!

- Note o-ring beneath the Allen-head - most consider Allen better than Phillip-head - you?

3. O-rings for sealing the bad stuff out

So the o-rings beneath the bolt head are supplied by a vendor that supplies Rolex watch-stem seals. The case sections are sealed with a custom 0.5mm diameter neoprene o-rings. We buy them all by the gazillion and use two to join the four principal servo sections.

Along with 10 tiny o-rings beneath the machine thread assembly bolt heads, plus the one at the output shaft, it makes 13 o-rings. And they're all from premium suppliers - the good stuff.

Did you know ProModeler servos are sealed with more o-rings than anybody else in the industry? True! Also means the servo can be disassembled for service without destroying glue joints. Glue. Can you believe some manufacturers glue their damned servos together. Sheesh!

- Stainless gear set - note the thin neoprene case o-ring between thumb and forefinger

So while our first recommended servo, the DS270DLHV is priced at $45 (mid-way between the $40 Traxxas commands for a 2075 and the $50 of their metal gear 2075R and 2075X) ours is faster, more powerful, and comes with super rugged stainless steel gears. Yup, brings us to yet more parts, the gear train!

4. The gear train

So the gears in the transmission of the servo take the relatively weak output of the motor and multiply it through combo gears, sometimes several hundred to 1 before it's at the splined output shaft. This, to create useful torque at that shaft, which we can harness, e.g. use, to move something. On a truck this may be steering wheels. Simple. Mechanics 101.

Recall earlier being referred to a Traxxas article about servos? If you took a couple of minutes and eyeballed the article, because the folks at Traxxas did a good job, they explained about metal gear servo versus plastic gears in terms of 'Most Traxxas high-torque servos use metal gears for extra strength and longer wear.' and I agreed. Metal gears *are* stronger and do outlast plastic gears (longer wear).

Metal gears are simply stronger than plastic. So now we're going down the rabbit hole a ittle bit further in regards to better parts. Are we agreed better parts make for better servos?

Let's talk about *better* gears. Better *metal* gears.

Various types of metals have various levels of hardness. Get too hard and it becomes fragile. Too soft and it can't do useful work because it deforms. Imagine gears made of lead. They would be terrible at the sizes we're dealing with!

Aluminum is soft also, but in servos, is sometimes used for the output spline gear. And the reason it works is a combination of a hard alloy like 7075-T6 plus an electro-chemical process called anodizing. Anodizing causes an hard oxide coating to form on the surface of the alloy. Anodizing aluminum gears actually creates what's called an anti-wear coating.

Works pretty good at reasonable torque levels. Doesn't work so good when the torque is high because the base material, the aluminum of the gear tooth, fails under high loads. Basically it will just fold over or actually tear off. Means the end of the gear set's useful life!!

So a materials engineer seeks to use a material that's harder, tougher, but one that won't wear quickly. For example, titanium is popular with some manufacturers for their servo gears. Is it because it's a good material for gears? Nope. In point of fact, it's our opinion it's pretty shitty as gear materials go. Super light? Yes! Strong as steel? yes! But soft. Soft? Yup, steel will scratch titanium. Fact. Steel will scratch aluminum. And brass, too. As metals go, carbon steel is pretty darn hard stuff.

Why do some companies use titanium for an output gear? Well, I have a theory (because they for sure won't even give me the time of day, were I to ask). Theory goes like this . . . they're using titanium gears because they're run by the marketing types have the upper hand on the engineers in the company.

And if there's one thing marketing types know how to do . . . it's selling. So another thing they know is there are two materials in the English lexicon, which make a guy reflexively reach for his wallet faster than a gal grabbing for the MasterCard at a shoe store. Those are *carbon fiber* and *titanium*.

Carbon fiber and titanium

Carbon fiber and titanium amounts to pure mental masturbation as visions of SR-71 Blackbirds flying 2000mph form in the mind, ditto trick formed-carbon parts, yada, yada, yada. And the marketing types know this. So they instruct their engineers to make gears of titanium so they can sell servos more easily to those too stupid to know any better the inexperienced.

And you don't even have to be an engineer to know this is true. Guess what the gears of a Formula 1 Ferrari are made of? Nope, not titanium, that's for damn sure. No sir! They're not made of aluminum or brass, either. And note, brass is a nice material for gears in low stress applications. Chief advantage of brass is it machines easily and is harder than aluminum. In fact, does well as the bull gear in a relatively lightly stressed combo gear.

FYI, the bull gear in the combo is the big gear. Maybe called the ring gear, or spur gear. Same thing. You're familiar with them from the gears in your rig . . . just smaller!

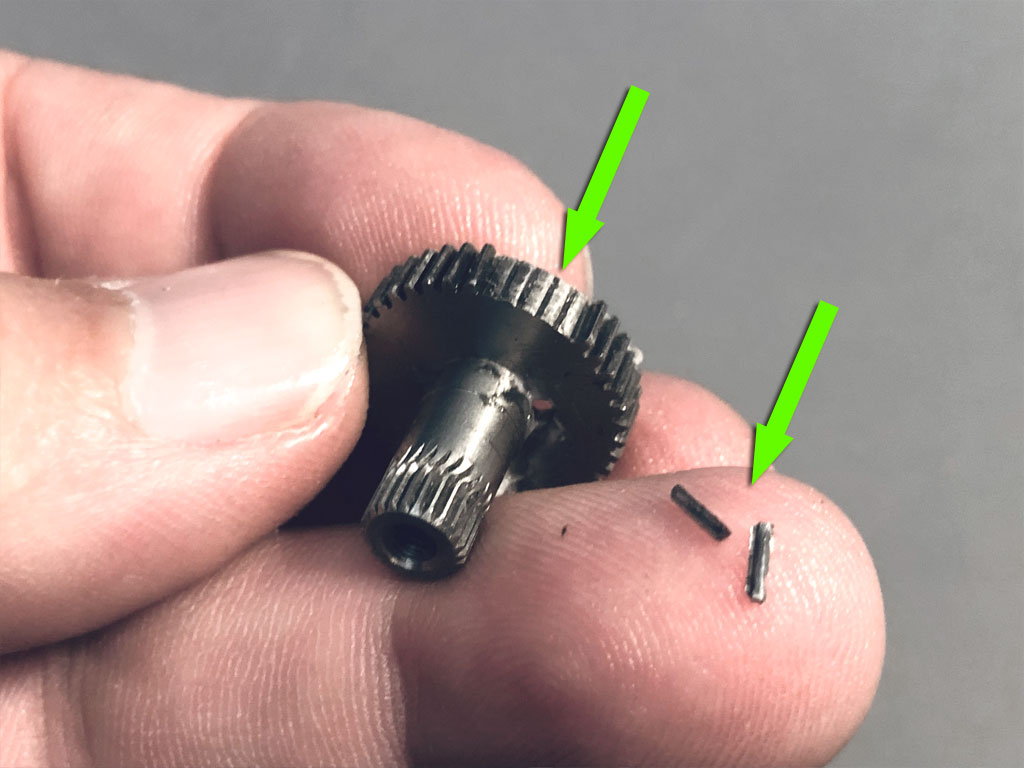

- Bull gears for servos are tiny, smaller than a dime, some smaller than a pencil diameter

The little gear in the combo? That's the pinion and they're typically made of carbon steel. Lot harder than brass. They're pressed together and the gear that drives a bull is usually made of steel, carbon steel is common. But better is when you get a steel/steel combo, instead.

- Steel/steel combo next to a brass/steel combo - the steel/steel is stronger and lasts longer

Go back and look at the photo of the servo where the o-ring was being plucked between thumb and forefinger. Specifically, look at the servo in the photo behind it. Note the use of brass and steel combo gears. Look familiar? Outs you in mind of the cutaway photos for the 2075X or 2075R on the Traxxas website? Yup, it should!

Of course, there are other metals than brass and carbon steel. With the DS270 you get an better material, one that's much harder and significantly longer wearing - stainless steel gear. The combo is made up of two materials and just like the softer f the two is the bul and the harder is the pinion, it works the same was with stainless gear sets.

The two types are 303 and 18/4. The ring gear is 303 stainless. The pinion gear is significantly harder, 18/4 (aka 304). And for our servos, at the sizes we're dealing with, stainless is the really, really good stuff.

Amongst gear sets, stainless are part of that mantra . . . they're the *better* amongst the parts knows as gear set parts. And if you have a choice, then you'd 100% rather the gears be 304/304 stainless than brass/carbon steel the same way you'd rather they be *any* kind of metal versus plastic gears. Again, just mo' betta!

- Stainless steel gears are MUCH harder and significantly longer wearing than brass/carbon steel

This brings us (finally) to what turns the gears. The servo motor. The part that gets hot when working as it converts electrical energy into kinetic energy - motion! The part of the servo we want to tru and keep cooler using an aluminum center case.

5. Motors

Just like you can buy either a brushed motor or a brushless motor for your rig, same holds for servos. If you reviewed the Traxxas servo article they mentioned the same thing. They used the term standard and coreless for the two brushed motor types, and we could also but the terminology is actually iron pole, coreless, and brushless. And no, we're not going to leave it to *you* to determine whether this is important.

We'll tell you straight up, all three are good. But if all the players are good, is a wide receiver better for the team than the fullback? What about the quarterback, is he better than the guard? Nope, all are important parts of a team just as point guard and a center are two distinct types. Ditto a forward and a wing! Same with motors, too. So it's not a matter of iron-pole, coreless, or brushless being better as in reliable, it's more a matter of different. Each serves a different purpose

Want speed? Coreless or brushless, either one. Want speed but don't want to spend as much? The brushed coreless is cheaper than brushless - but both are fast. Want durability? Brushless by a country mile. Want a good price? Iron pole walks away with the crown.

So I've already spent twice as many word on this as Traxxas in their servo article and honestly? We haven't really even so much as scratched the surface. This little graphic is the Cliff Notes regarding servo motors . . .

In order of increasing performance, iron pole, coreless, brushless. In order of increasing price, same order, iron pole, coreless, and brushless. In order of durability, same order, iron pole, coreless and brushless.Clearly, iron pole is about price, brushless is about performance, and coreless is somewhere in the middle. Racing/ You want fast servos. Crawling? You want servos with grunt!

So here's the thing, want to really learn more about servo motors? We have another article for you. It's titled simply enough . . .

. . . and what we did is we took samples of the three basic types of motor (if not the exact ones as other brands, of the very same type as we at ProModeler, Futaba, Hitec, Traxxas, Spektrum, everybody uses - iron pole, coreless, and brushless, and cut them open on the lathe. What for? To show you what actually makes them different!

Below is the hero image for the About RC servo motors article. That's an expensive brushless motor - totally ruined - laying in my fingertips. Since they say a picture is worth a thousand words, we hope this picture intrigues you enough to delve in.

I promise you this, if you'll do a deep dive into the motor article you'll come out the other end as the expert in your group of mates. Nobody will know the shit you do about motors. You'll be the guy *everyone* turns to for advice . . . the servo motor guru!

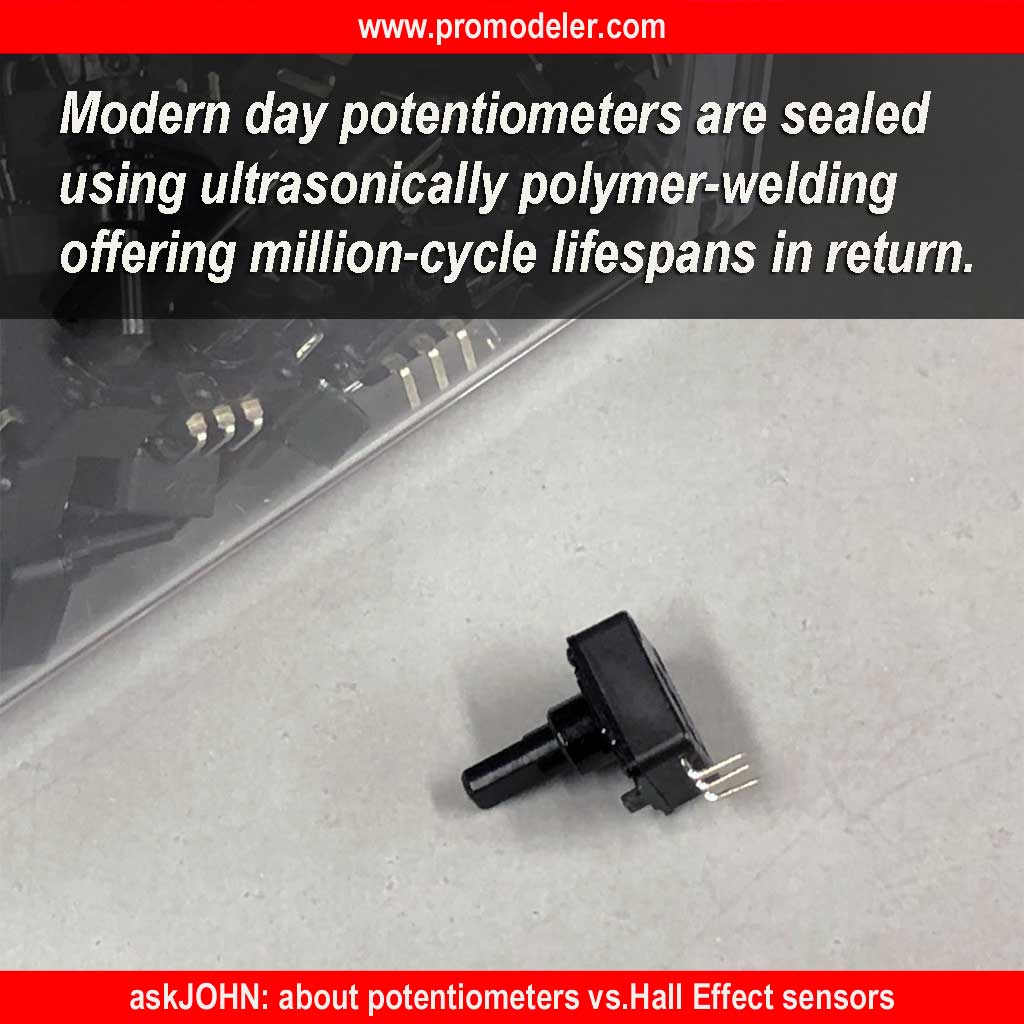

So what's next in the story of better parts as we educate you in how to figure out what's important to you? Next is to do with the potentiometer. And this is a serious place to demand better parts.

6. Potentiometer

The potentiometers is what determines how well the servo centers. It sits directly beneath and attaches to the servo's output gear. At ProModeler, our attitude is exactly like that of top drivers, any servo that doesn't center worth a damn . . . isn't worth a damn, either.

Nothing is more important than centering!

So for us, centering is job one. And if you care in *any* conceivable way about high performance, centering is the FIRST thing you think of. For a pro driver? Centering comes ahead of price, torque, and speed. Every single time.

Pot-wise we use the famous Japanese Nobel 1mc. People ask why we don't use a HE (Hall Effect) sensor type. We laugh and explain this is why we earn the big bucks - earned by making the hard decision like how do you want things to fail? This, because everything under God's stars will fail eventually.

So a mechanical pot like the Noble 1mc fails gracefully. Basically begins to jitter about center (where it spends the most time), so as it wears (it's rated to 1 million cycles but eventually you get there) it tells you. How? With tiny little jitters. It's giving you a heads up! And HE sensor? Those fail like light bulb, no warning, just poof. So which would you rather, a bit of warning so you can schedule maintenance, or no warning whatsoever?

And FYI, HE sensors have been tried by all the serious players in the business. We all return to carbon wiper type pots. The very best like the Japanese unit we use is a 1 million cycle unit. That's a lot. Very best money can buy. And we use it in every micro, mini, standard, and quarter class servo we produce.

Want to know more about the why of potentiometers? Read more within this article;

As for the Nobel 1mc we use? Expensive. We can buy 8 HE sensors for one 1mc. There's also a clone made in east Asian, six for the price of one genuine item. And the clone? Looks just like it. Doesn't hold up.

Centering? It's important. Racer with a rig that won't track, bit of vagueness about center of it won't settle down and resembles a rabbit zigzagging to avoid become a hawk's dinner? Drive wil tell you, it sucks. Servo's fault.

Or almost always the servo's fault, and if not a shitty pot, probably a worn case. but usually a worn pot when you dig into it. As for why? Always about saving money. When there's a beancounter in charge, he/she won't listen to engineers.

Me? I've spend 40 years of my life watching products being optimized for cost instead of for making them better. Only company I've seen optimizing for better is Porsche. And us. You may not know us because we don't advertise. Never had to. Sold every servo made, sometimes with wait-lists. Want an example of optimizing for better? A tangible no bullshit example?

Remember when the Traxxas servo article mentioned three different size servos, micro, mini, and standard? Below are two servos, the 2022 vs 2023 ProModeler DS160CLHV mini.

In 2022, we made them with brass/carbon-steel combo gears, but in 2023, taking advantage of our fast growth to negotiate better deals with far east gear suppliers, we negotiated one Hell of a good deal. How good . . . 303/304 combo-gears for just 4% more than brass/steel . . . and we upgraded the servos, and held the price.

That's right, same price since 2019 when we created it. But it's now an even better servo.

- We upgrading the minis from brass/carbon-steel to all-stainless . . . same price!

Circling back around to potentiometers. That Nobel 1mc? Best money can buy. Period. And when it comes to better parts for your servo, you want the genuine Nobel 1mc instead of some bogus clone or anything bought by the beancounter!

Your money, do whatever you want but in terms of the pot? Heads up! You want your servos with the good one. Consider yourself warned.

So this almost brings us to the end. The potentiometer in the circuit is what informs the PWM circuit of where it is in the sweep. It's the feedback part of the control loop. It's what talks for the elements of the electronics which are mounted on a printed circuit board. PCB is an acronym for Printed Circuit Board. So now let's learn a little bit about this part.

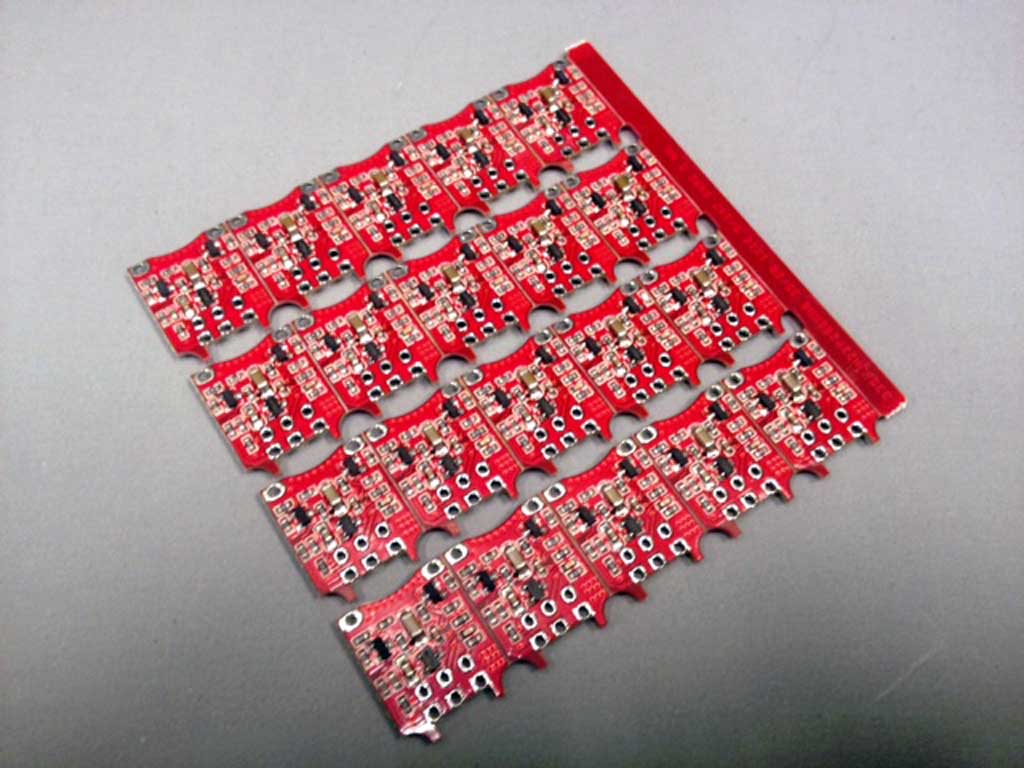

7. PCB - printed circuit board

We're about done with discussing things that make a servo better for you. We've been focusing on better parts and trying to help you understand things like selecting servos with stainless steel gear sets will be better for you because they're stronger and last longer.

We've dealt with six of the fundamental servo-parts. These being the case, o-rings, bolts, gear train, motor, and potentiometer. We spoke in terms of seven parts making up your servo, any servo, any brand and how if the individual parts were better, then you'd get a better servo. So here comes the last of them . . . the 7th is to do with the PCB, and the components soldered to the board.

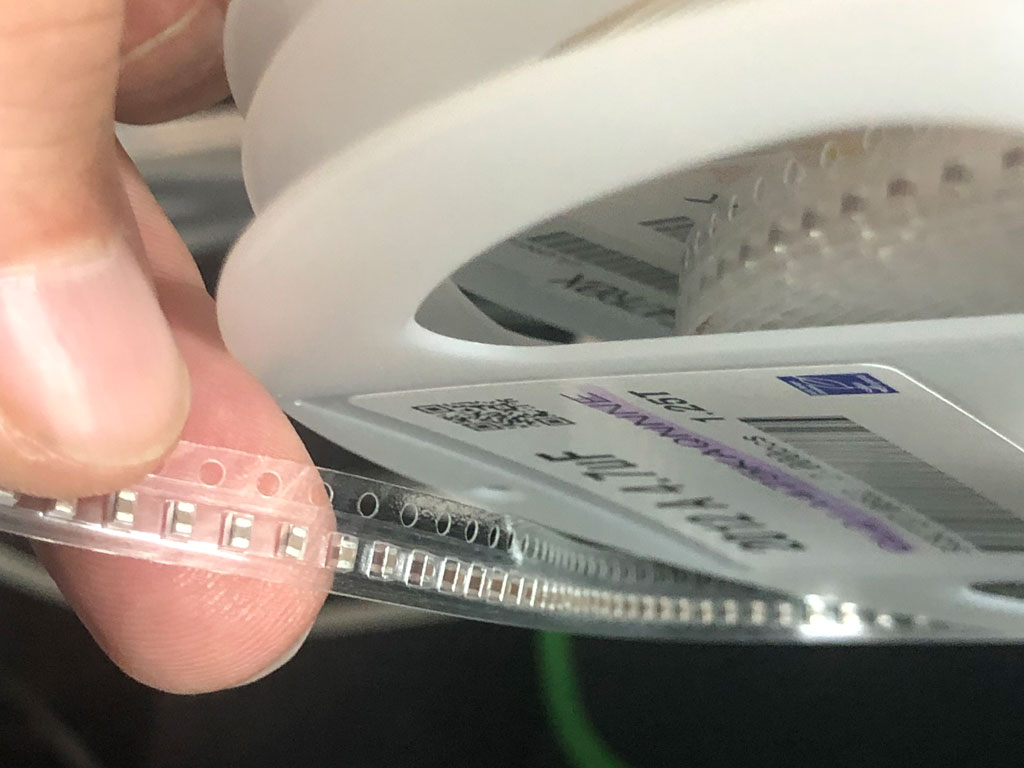

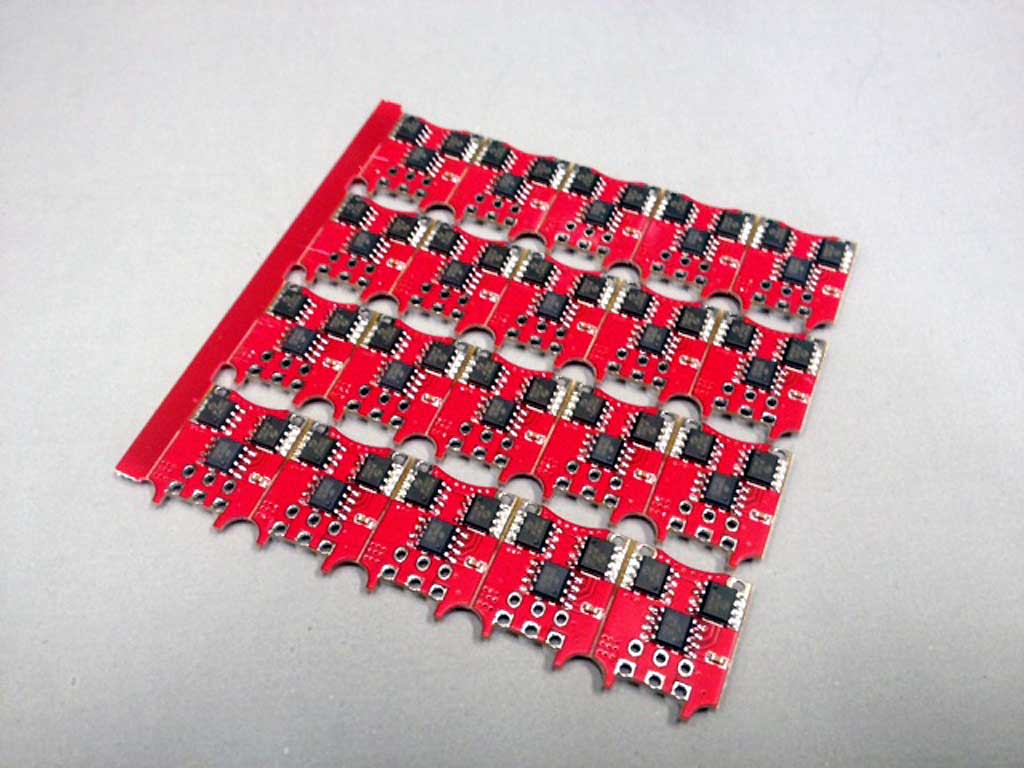

Yes, we're counting a butt load of itty-bitty component parts as *one* when we speak of the printed circuit board, or PCB. The individual boards actually begin as several together on a card. These are connected in a way similar to stamps on a sheet and when cracked along the perforation result in an individual board. Just like getting an individual stamp from a sheet of them!

- Card of individual circuit boards before being separated - this is one side

So people often ask about the process of making the circuit boards. We don't do the production quantities, just the prototypes. This, because production quantities requires a huge facility with a butt load of pick and place machines like this one.

Part of how you get a better price isn't using shitty parts, it's being smart and using people who are experts in their field. No sense in us replicating a huge building full of pick and place machines when we can have them made after we prove the board design!

One's enough for our purposes.

- This machine is called a pick and place and it literally places the components on the board

Those reels you see below on a common hub? Each reels is loaded with individual components on a tape. There are hundreds and hundreds on a reel and each reel is a different component. What component? Whatever is required for the particular board being made - duh! So these components can be FET, resisters, processors, diodes, whatever!

And here's the thing, if you're willing to pay about 15% more, these component parts can be bought in MIL-SPEC (military specification), and we do. In fact, anything and everything that can be bought for a ProModeler servo is MIL-SPEC. The other guys? More often than not, we see decisions made - in our opinion - by the marketing team instead of engineering within other products. So this informs our opinion about the product line and who runs the place, but we won't speculate. In a bit we'll share some examples that are easy to spot . . . patience.

For now, let's back to individual electronic components.

- Individual components are actually placed on the boards by robot from reels like this

Once placed on the board, the next step in the process is the reflow oven. These can have temperature zones so that components on one side aren't melted off when the board goes back through to solder the components on the flip side. That's right, we use PCB with components on both sides to save space. Doesn't make us geniuses, everybody does this because the inside of a servo - the space within - is precious because other stuff has to live there, too. Not just the pot and motor but individual wires connecting things!

- The reflow oven is the last machine step in the automated process

And this is why when you flip the card over, you have components on *both* sides of ProModeler servo PCB (printed circuit board). Although to be honest, servo circuits are about as elementary as it gets in the electronics world. Saying PWM circuits are not rocket science. As for the card itself, being red means nothing, sometimes they're green or black. Just different suppliers.

- Flip side of a card shown previously, this, before the individual boards are separated

Next the boards go to assembly. Again, these are done one-by-one . . . by hand. Production is done by hand just like we do the prototypes to prove out the design, but afterward they go to an assembly shop full of people who specialize in miniature solder assembly.

These are folks that adeptly perform batch assembly of production quantities (thousands at a time) looking through a lens to magnify the size of the work. Gets tiring quick.

For example, after a run of control boards for a refrigerator manufacturer, or whatever, they turn their attention to boards for us. Afterward, boards for someone else. Depending on the job they may be doing the same boards for months on end. Depends. Us? They do a batch in three days, maybe four. This being, incidentally where the boards receive the lead, motor, and potentiometer, which once attached become what we call a hotsection.

Next step is stuffing it all inside a servo!

- Soldering to the PCB is tedious work done under 3X magnification

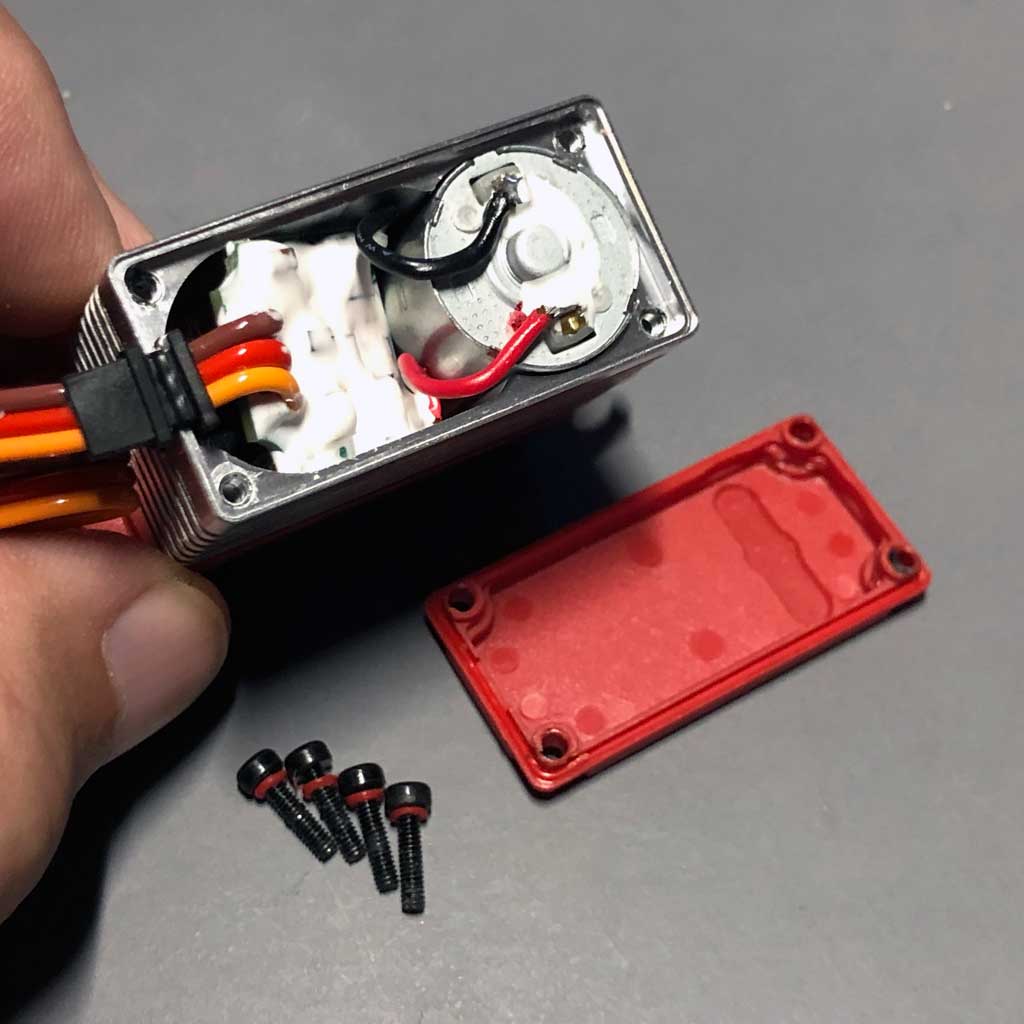

Inside your servo

If you feel like it, remove the four screws securing the bottom cover on to expose the electronics side. All you need is a 1.5mm Allen and you're in business. Void the warranty? Nope! Taking a peek won't hurt anything!

Yet if you look at the PCB of your servo, you'll see very little. Why? It's because of something you get with a ProModeler servo that you don't get with hobby grade servos like you are typically offered by the marketplace. Ours meet three MIL-STDS and these include environmental intrusion, shock, and vibration. Do these matter to do? Dunno, they should but it's your money. We're just informing you what's what because *you* are who decides what matters to you. So the reason you don't see much is the PCB gets coated in potting compound.

Our electrical engineer customers immediately notice this. Basically, we protect the PCB from shock vibration with a conformal coating called potting compound. It's a two-part epoxy like material that remains semi-flexible (and it may be clear, black, or white, and once again, color doesn't matter).

- The white coating is two-part potting compound and once it sets it protects against vibration

Referred to as potting compound on the civilian side, we call it monkey-snot. Why? Simple, it's because it's such a sticky mess to apply. And it stinks!

Basically, this stuff is applied to the PCB and it oozes between components and once it sets this process is what lets our servos thrive in harsh high-vibration environments. The potting compound reinforces the components mechanically - just like shoulder pads on a football player protect him from impact damage. Same thing.

And this is actually an aerospace-grade technique. That it makes ProModeler servos more valuable to the defense industry than hobby grade products is a given.They're our principal customer, not hobbyists. Like we don't spend for MIL-SPEC and do all the MIL-STDS product certification for our health!

So when you buy DL-series servos like DS270DLHV and DS360DLHV, your servo meets three MIL-STDS! There are five servos in the DL-series!

Part of what makes the ProModeler DL-series servos *better* for you than competing products is that unlike hobby-grade servos, they're built to meet military standards (MIL-STDS) and thus, they're subjected to these tests.

MIL-STD-810G-Part 16

- Shock - Test Method 516.6

- Vibration - Test Method 514.6

- Water intrusion - Test Method 514.5

In part, this is due to the requirements of our primary customer. However, because we're modelers and have knocked a servo off a workbench, experienced crashes, jumped a rig 40 feet and tumbled to a stop as we misjudged the landing, then we also know a thing or two about the school of hard knocks!

That, and nitro engine vibration, gear chatter, plus how a summer afternoon pop-up rain shower or a shallow stream crossing may drench a servo. So it means MIL-STDS are tests ,which are important for civilian users as well.

So if you're looking at another servo, one which offers similar performance and pricing, but hasn't been tested to military standards, then which would you rather have?

Better parts. Better servo. The formula is simple.

Wrapping up the 7-parts of a servo, our focus has been principally on educating you about what goes into a servo, and what's the good stuff versus what's not so good. This, in hopes of teaching you to understand exactly want it is you want in a servo. After all, it's your job to look out for numero uno, right?

So we're about done with the educating about parts thing, e.g. what benefits you get from features that make a servo better for you. Basically, we've been focusing on what makes some parts better for you than another.

You've learned about gears, like how selecting servos with stainless steel gear sets

means getting more bang for the buck. And not just because they're stronger than other metals but because they'll last longer. And unless your money grows on tree, this is important, right?

We've discussed the 7-fundamental parts in rather more depth than Traxxas does in their servo article but there's a reason. Our focus is just on servos while theirs is, naturally enough, on their cars and trucks. Obviously, servos are important to them, but so are tires and wheels, drive sub-systems, like motor, ESC, batteries, body parts, suspensions, shocks, etc. and by necessity, this means relegating the individual components, specifically servos, to 2nd place in *their* big picture. Not the case with us where servos are the only thing we think about.

So we think about servos and nothing but pretty much how Smith & Wesson want to deliver a better firing experience in each weapon. Same with us, servos are our 'thang'.

So recapping, these are the 7 fundamental parts of a servo

- the case

- the bolts holding it together

- o-rings for sealing out bad stuff

- the gear train

- motor

- potentiometer

- and the PCB (upon which are soldered teeny-tiny electronic components)

And as you've learned, there's more than just seven 'actual' parts, but these 7-components stand in for all the various individual bits & bobs. What's more, you're now actually at a point of understanding what makes the difference between junk vs. the good stuff!

On Traxxas upgrade servos vs. ProModeler

So circling back to the Traxxas 2275 (the stock servo in most Slash rigs, the one in the blue case) and the upgrade servos (black cases and stock in some rigs), servos like 2275X and 2275R, plus pricier upgrades These are the servos which Traxxas mention in their servo article like 2250 (High-Torque 330) and 2255 (High-Torque 400). Added to which, maybe you recall I mentioned a rookie buyer focused first on price, then torque and speed. So here goes, let's put the hay down where the goats can get it.

Let's see if just know, or whether you actually have integrated the knowledge of the 7 servo parts and reached understanding! The Zen of servos and whether you actually perceiving their true nature.

For example, the 2075X gives you the same 125oz-in of torque as the 2075. Both transit in 0.17sec/60°, with the major difference between the two (other than the case is black in the 2075X/2275R) being metal vs. plastic gears. Price difference is an added $10 so the price goes from $40 to $50.

If you *had* to buy between those, then *I* think it's a no brainer (and totally worth the extra tenner) to get the 2275X because I agree with Traxxas' assessment, the metal gear servo is more durable. Easy win for them. Bet they sell a ton of those, too. But since *we* represent ProModeler, let me fight our corner, now.

Note, before this, let's recap a bit. We've spent time educating you on the good, the bad, and the ugly about servo construction. And what features were worth having, and why. So now I am going to make *our* servo recommendations for a Slash SCT. I'm doing it now because I am secure in the knowledge you actually have a pretty darn good idea of what's what. You certainly know more than when we first me.

So *now* I feel it's actually fair for me to tell you what you might want to get servo-wise from our lineup versus theirs because now you won't be an easy mark. This being defined as someone who doesn't know shit about servos.

In fact, if you've done the side jaunts I recommended like the article about RC servo motors and one regarding potentiometers, then never again as long as you live will a servo vendor pluck easy money from you by baffling you with bullshit.

Baffling you with bullshit. Sound familiar? The full quote by WC Fields was actually . . .

. . . major point being, now you're not easy. Not any more. So here's *our* advice divided into three servos - good, better, and best - or put another way, budget build, racer dude, and the hooligan basher!

Budget Build

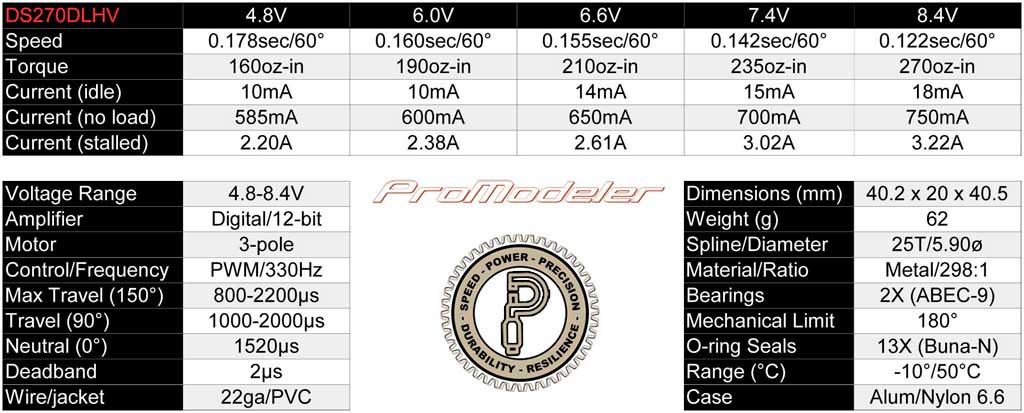

If you're on a budget, like just replacing your 2270 with a 2275X or maybe 2275R (although NOWHERE could I find a spec for the transit speed of that servo, they just said faster than 2275X), then the smart money is on either the ProModeler DS270DLHV or the DS360DLHV.

This is because for $45 and $50 respectively you get mo' betta for your money - on 6V

- DS270DLHV -190oz-in vs 125oz-in (+52%) - and - 0.16sec/60° vs 0.17sec/60° (+6%)

- DS360DLHV - 270oz-in vs 125oz-in (+160%) - and - 0.20sec/60° vs 0.17sec/60° (-16%)

So with the DS270 you get ~50% more torque and a skosh more speed for 5 bucks *less* than their 2275X.

With the DS360, especially if you have larger tires, then +100% more torque is valuable *and* you probably won't care if the speed is a tad less for the same $50 because you can't really steer larger tires with either their 2270 or 2275X.

BUT THAT"S JUST TALKING ABOUT PRICE, TORQUE, AND SPEED . . . LIKE A ROOKIE!

You *also* gain better cooling with a finned alloy center section so your investment lasts longer, and this is important because with stainless gears, the gear train won't break as easy as plastic and will last a LOT longer than the brass/carbon steel metal gearset of the 2275X. And it'll center better for longer.

If you thought about that, then you have begun thinking like a pro. Sure, price, torque, and speed are important, but the parts that make up the whole are what really dictate what you should get. A case with cooling fins, stainless gears, MIL-STDS, etc. Bottom line? Think deeper!

And of course, it's your money, so if you're on a budget, then we've just shown you how to get more bang for the buck!

8.4V versus 6V

Budget build gets better because on 8.4V instead of 6V, we show you in an easy how-to article titled: Bypassing the BEC and other power subjects that you can for just the cost of a $10 special wiring harness, keep using your stock 6V Traxxas radio system and upgrade to a 2S-battery or 3rd party BEC and it not go poof and release the magic smoke.

This lets you power your servo at full song. By this meaning the specs we power it at the maximum voltage. So we rate our servos at max voltage for the same reason a gal puts on lipstick and perfume, to get attention. That, and if we didn't - whilst everybody else does - then we wouldn't shine as brightly.

Traxxas makes it a point of observing their servos are rated at 6V for pretty much the same reason, to ensure if you're comparing, you do it fairly. And this is why I compared ours to theirs at 6V - to keep things fair.

But since you can opt to run our servos at 8.4V, then we're not going to hide out light under a bushel, we're going to tell you about it. Here goes.

- DS270DLHV -270oz-in vs 125oz-in (+116%) - and - 0.12sec/60° vs 0.17sec/60° (30% faster)

- DS360DLHV - 360oz-in vs 125oz-in (+188%) - and - 0.14sec/60° vs 0.17sec/60° (17% faster)

So without breaking the bank, you can upgrade your Slash steering . . . big time!

Racer Dude

If you're into racing your Slash, the stock servo won't cut it. Even the faster 2275R won't. So at a minimum, figure on the DS270DLHV on a HV system to be competitive because 0.12sec/60° will let you dive under most guys when racing to the apex of the corner and this is how you beat your buddy (or competitor) in the heat.

But to be really competitive, Traxxas suggests their more powerful 2250 (High-Torque 330 Blue) at $80. Pretty good servo, too - metal gears, fairly quick coreless motor, alloy center case.

Bit slower because they geared it for power so 0.19sec/60° on 6V (couldn't find specs for 7.4V although they do rate it for this). So for racing, run your servo on either a 2S battery or 3rd party BEC (like the Castle CC BEC PRO 2.0. And as long as you protect the receiver with that little $10 harness we offer, their either the aftermarket BEC you solder into your system, or a simple B2S850 battery (for about half the price) you can get more ooomph out of their servo just like you can from ours. How much more? Sorry, no clue. I looked and never found specs.

As to the battery, for heat racing I'd advise the B2S850. Looks like this. Click the link, but not expensive. More later. And note; this pack is enough to run 5-6 heats, maybe more. Charging a small 2S with what you already own is easy enough and doesn't take long, but it's your call whether to us ea pack or solder in a 3rd party BEC.

$40-50 servos vs. $80

So what does $80 get you with ProModeler? Ahhh, glad you asked! We'll only yap about 8.4V specs going forward because a) Traxxas 2250 is rated to handle 2S packs, also, and b) racer guys aren't going to accept inferior servo performance. Not when it's so easy to use HV with their old fashioned Traxxas 6V RF systems as we're shown and extract everything the servo is capable of delivering. Or upgrading to any aftermarket RF system and get 8V capability out of the box.

So here's the thing, *this* is where you have to begin using your judgement. I'm not the type to baffle you with bullshit because we sell every single servo we make without the nonsense. So now it's time to begin using the brain God gave you and the education we've helped open your eyes to.

So presuming racer guys is never going to stick to 6V when winning is on the line, the 2250 beats the pants off the ProModeler torque-wise by a country mile, call it 350oz-in instead of 300 when on 8.4V (trust my experience, I bet I'm not off by far if anyone ever finds published specs), and speed probably breaks into the 0.17sec/60° range, but look at the speed spec of the DS255BLHV, that thing is FAST . . . like quicker than a bird drops a load before taking wing!

So 350oz-in beats 255oz-in means ours is down 27% torque-wise, but on the racetrack, the Traxxas 2250 is 260% slower than the ProModeler DS255BLHV. And when you're running laps, servo speed is king! Ask racer dudes, you'll see. But what if you have another $10? Glad you asked!

Power and speed, both!

Here's the thing, for another tenner, $90, we offer the DS415BLHV and this one specs at;

DS415BLHV - 415oz-in and 0.052sec/60

. . . so you get maybe 20% more torque than their Blue servo and it's got a better than 220% speed advantage!

And let's not forget . . . better parts. Both the DS255BLHV and DS415BLHV are built better. Does it matter to you? Let's see!

- Nobel 1mc potentiometer vs who knows?

- Finned 6061-T6 aluminum center case vs smooth as a baby's butt alloy (unknown spec)

- Stainless steel gear train vs brass and carbon-steel

- Three MIL-STDS

- 10-bolts (Allen head) vs 6-bolts (4-cheesecutters + 2 machine thread) all Philips head

- Brushless motor vs coreless motor (did you read up on this? Runs cooler, 5X service life)

- Torque +20%

- Speed - way, way, way the heck faster!

- $90 vs $80

We think this is a no brainer if you're racing - but - what matters is what *you* think.

- DS415BLHV is a beauty - modest price, brushless motor, fast as a greased pig, and rugged!

Hooligan Basher

The guys bashing can be gentleman bashers or outright hooligans intent on making YouTube videos. We don't know you, have never driven with you so this is going to be your call.

Against the Traxxas 2255 (High-Torque 400 Red) we have two suggestions. Does Traxxas have anything better? Honestly, we don't know but no matter what, dollar for dollar we're gonna kill them.

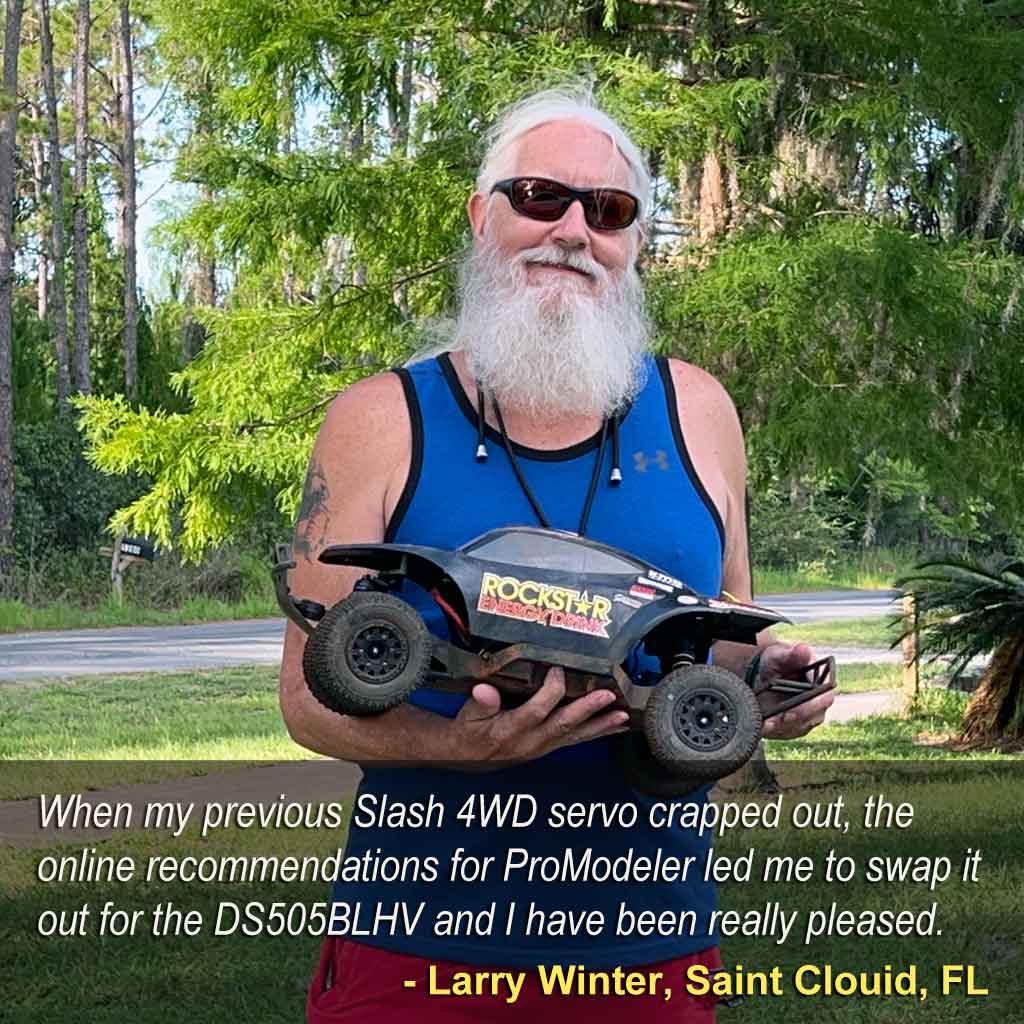

Against their 2255 High-TorqueRed, for the same $100, we offer DS505BLHV and before we get into the head2head, If you've not broken the code, here's what these numbers mean . . .

- DS = Digital Servo

- 505 = Torque Rating in oz-in

- BL = Brushless motor (theirs is too, did you read up on this in About RC servo motors yet?)

- HV = High Voltage (up to 8.4V

So because we've never driven with you and have no clue how you drive, making a recommendation of which servo is best is tricky. And we know everybody and their brother online has an opinion maybe leaving you confused because there are so many alternatives and use cases, then we'll start with just the raw numbers . . . what rookies use.

- Traxxas 2255 - 400oz-in and 0.15sec/60°

- ProModeler DS505BLHV - 505oz-in and 0.098sec/60°

Honestly? We kill the Red on torque *and* speed for the same money. Added to which, a laundry list of better features from which you know enough to suss out what benefits are in it for you. We're speaking again of what pros delve into like;

- Nobel 1mc pot

- 6061-T6 finned case

- Stainless steel geartrain

- 10-bolts with Allen vs 6-bolts with Phillips

- Three MIL-STDS

- All-alloy case

. . . and this last is the biggie is you're bashing. This is because instead of a hybrid case of polymer and aluminum center, the DS505 gives you an all-alloy case.And folks, this is better by a country mile if nothing else, just on the basis of more rugged! Feast your eyes.

- DS505BLHV is an all-alloy beauty of the first water . . . rugged, fast, and priced right!

So here's the thing. We can wax rhapsodic about the DS505 until the cows come home. This is one of our best servos. Very best? Nope, we have more expensive servos that are faster and stronger but honestly, this is a 1/10 rig and for a smaller rig like this, it's about all you'll ever really need.

But maybe you just wanna spend more because you got more money than God? Then KYO, begin by eyeballing the DS635BLHV, which is one of four BLS2 series standard class servos we offer. The BLS2 are superior in every regard to BLS1 servos like DS505/630/930 because they have larger gears, larger gear shafts, more expensive motors that are dollar for dollar more powerful and faster. Put another way, better by every single measure same as a Porsche 911 bests a Cayman. Not saying the latter isn't excellent but the McDaddy is the 911. Same thing with BLS2 vs. BLS1 ProModeler servos *but* they also cost a fair bit more. Fair warning.

So maybe you're wondering how the DS505BLHV compares to some Amazon no-name for 2/3-3/4 the price? Well, now that you're more educated about the ins-and-outs of servos, I'm going to send you to this article:

. . . where if you spend a few minutes, you'll never again wonder if one of these is best for you. Again, my refrain . . . it's your call. Go learn about what makes one of those totally different from one of ours.

This fellow Slash owner tried it for himself with an Amazon special and found out the hard way.

- They say experience is a hard teacher because she gives the test first, the lesson afterward!

Some people learn from the experiences of others, which is why I shared this photo. Our customer? He replaced the Amazon servo with a DS505BLHV and that was a couple years ago!

So would you like to *really* know more about whether the DS505 is for you, or not? Then I'm about to share more reading with:

. . . where a fellow heavily damaged two DS505 servos in a crash. So he called and explained what had happened (naturally, I asked for pictures). When he asked if they could be salvaged, or if he should just pony up for replacements, I suggested nothing ventured, nothing gained. Worst come to worse he's out a few bucks for postage, right?

He returned them, the tech cleaned them up and I got a call along the lines of, 'John, you won't believe this shit!', which resulted in me paying a visit to the R&R department to see what they had (I'd forgotten about the conversation with the guy).

So my eyes went wide, and I whipped out the ever-present cell phone and began taking pictures. Here's one to motivate you to go read up on servo repair article linked above.

- Despite the hard 303 stainless steel, fellow destroyed a set of gears - eyeball the splines!

Questions & Answers

So we'll use the Q&A format to wrap this up because we suspect the right answer for you regarding which is the best servo for your rig will probably become obvious based on how the folks asking us for advice drive vs what you think they need vs what we recommend. Think of this as a way to test your knowledge, which you've gained by reading and learning with this article.

Facts are the range of skills vary wildly but enthusiasm is the one common factor.

That said, there are a wide range of how folks use the rig. Some mostly bash in their back yard alone after work or school. They're pretty chill with their rig and the primary goal is to have fun for a couple of packs without breaking anything, cleaning it up and putting it away for the next day. These are mostly stock rigs where the servo is replaced with one of ours but the customer isn't made of money

Others are meeting with friends at a local park or empty lot and while they aren't really organized, they can get pretty spirited in their driving. Especially as this great SCT lends itself to impromptu racing on improvised courses making use of whatever the terrain offers in the way of complexity. The sheer fun and exhilaration leaves everybody laughing and making plans for meeting up again. These guys vie with each other in upgrading their rigs with better motor/ESC.

Some folks are actually racing at an organized level with this rig. It's called a short course truck for a reason, capisi? This is - after all - the actual purpose of the rig!

And then there are folks just bashing the shit out of it. And the ever present YouTubers out for views with outlandish antics using a Slash because it's such a well balance package and for which upgrades are readily available from the usual suspects like Vitavon and Hot Racing on the high end, eBay and Amazon at the low end, plus a plethora of stuff available online through other sources and for cheap compared to 1/8 an 1/6 rigs.

Q1. I saw some recommendations for your servos on Facebook. I have a Traxxas Slash Ultimate 4X4 and I mainly race on a clay track. What your best servo for my rig?

Q2. I have a Traxxas Slash 2WD Short Course Truck I received for Christmas. I broke the servo the first time out and they replaced it under warranty. When I broke it again they said it was my fault. So I bought another but with metal and now I've broken it too. A guy at the track uses a ProModeler DS505BLHV and said that's what I should get but you have so many other servos now I'm confused. What's the best servo for me?

Q3. Got a Slash 4X4 VXD I use for bashing. Been buying 45Kg servos off Amazon and I'm tired of that. Heard good things about yours so what's the best servo you make?

A1,2,3. What's the very best servo for a Traxxas Slash whilst racing? Honestly, it depends on what you're doing. Thing is, many of you ask and often there are two uses cases, racers and bashers so while I don't know you I'm going to make four recommendations based on our experience with folks running 1/10 rigs, both 2WD and 4WD.

First, while we have less expensive servos with all-metal gears, the four I'm going to recommend have brushless motors, and all-steel gears for durability. Note; technically all-steel is all-metal but all-metal is not all-steel because all-metal gear sets may have steel as well as brass and aluminum in their make up. There's a difference, OK? Anyway, all-steel is the best there is, all-stainless steel is the crème de la crème.

Second, there are iron-pole motors, coreless motors, and brushless motors. Brushless motors are the best but If you don't know what brushless servos bring to the game, then it pays for you to review this article titled About RC Servo Motors before you do anything else.

Clicking this link will open a new browser tab so you won't loose your place but heads up, this is an intense 30-minute read you'd be wise to read more than once. You can grok the basics in about 5-minutes just by reading the photo captions, but to really understand it, plan to review it more than once. You've been warned.

Third, let's cut to the chase; these are the four servos I'd guide you to for your Traxxas Slash. Which one is best for you? Dunno. Sorry but you're going to have to decide on your own. And while I know this seems like I'm basically throwing you into the deep end, let me toss you a life preserver.

If you review the use cases I'm about to share, I suspect you'll see some that fit your circumstances and will help you decide what the best servo is for you. Note, as usual these servo links open in a new tab so you don't loose your place.

- DS255BLHV - best for racing - mid level skills - especially if using TQi receiver with gyro

- DS415BLHV - better for racing - high level skills

- DS505BLHV - good for bashing and racing because of durable all-alloy case

- DS635BLHV - best for racing 'and' bashing - gnarly 15T spline - same as 1/5th servos

The last two, the ones recommended for bashing and racing, or racing and bashing sound like the same but the first is the emphasis. Both have an all-alloy case.

A durable servo arm for these is the PDRS25-25T while the last of the recommended servos (and also the one that's most expensive), needs a special version of the same servo arm but for the gnarly 15T spline with which a BLS2 servo is equipped, same arm, different spline so it's part number is PDRS25-15T, instead. Note ending in -25T or -15T . . . heads up!

Q5. I just got my Traxxas Sash and the blue servo broke pretty quick. The hobby shop guy sold me a 2275X and I just broke it, also. I'm just playing around a little bit and I'm still not real good. The servo broke when I hit the dog (she's OK). Anyway, I'm 12 y/o and my Mom is divorced so we don't have a lot of money. What do you recommend?

A5. I'm going to guide you to the DS270DLHV as the best bang for your buck. This servo is more durable than the 2275X and more powerful but only $45 versus $50. Because you're using a 3A BEC, and outputting 6V, this is a good match for your stock electronics. And if you want to equip your rig with bigger tires (think Pro-Line Trenchers, or similar) then spend an extra $5 and get the DS360DDLHV, instead. The extra torque will come in handy. And to get the most out of it, when you get to feeling you wish you had a stronger servo, buy the $10 harness adapter and B2S850 battery pack and really juice those servos up.

Why is this? Let's look at the specs tab for this servo (every servo on the ProModeler site has one similar to it). So eyeball the chart.

This servo is a far wiser use of your Mom's money and since I can read between the lines and see you really don't want to be too much of a drag on your Mom's finances, I congratulate you for being mature beyond your years. Well done!

Last thing, if you ever want more get more oomph out of the DS270DLHV servo, then we have a special wiring harness that lets you keep using the stock Traxxas 6V radio system whilst feeding the servo rated voltage of more than 8V using either a battery or a 3rd party BEC.

Review this article to learn the ins and outs of how this works.

Finally, let's address the various use cases in greater detail.

If, for example, you're using the stock Traxxas radio system (transmitter and receiver, and ESC), then the stock BEC really isn't really up to the job for sure with the last three servos and it'll be a maybe good enough with the first one. Honestly, I'd advise using a harness/battery combo, a dedicated pack to supply the servo sub-system to extract all the performance you've paid for.

Basically, a dedicated pack adds another battery to your rig and while it adds a bit of complication, a single charge will last all day so it's not much of an inconvenience. All you'll do (if you run it flat) is field charge it exactly like the guys running nitro rigs do. The big advantage for you is a) you don't need to upgrade your stock ESC or b) the Traxxas radio which is otherwise quite decent.

Note; if you already have invested in an aftermarket radio capable of using a 8V source, then get what I recommend below - except - for the harness, which you won't need.

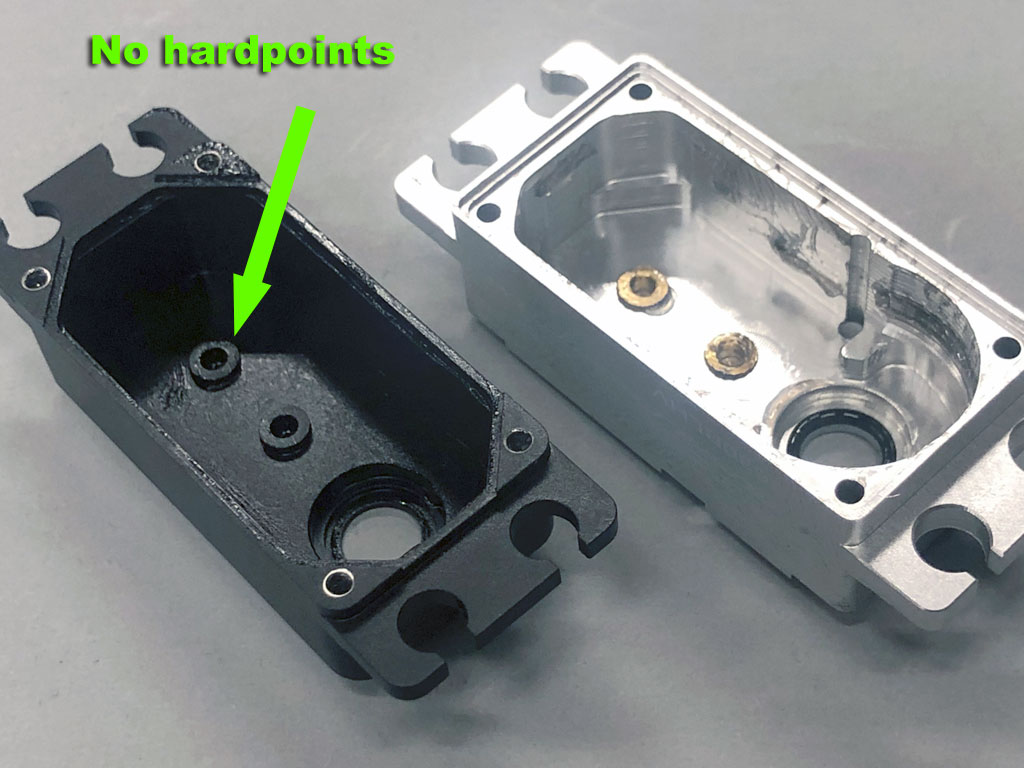

Q6. I have been bashing my Slash about a year or so and upgraded to a Savox 2290SG Monster. I have been jumping with skateboard ramps and it's been a great servo but while I thought it was unbreakable (reason I bought it from the hobby shop), when I crashed this last time the guy at the store said he ordered the gears but couldn't fix it because the case was damaged where the shafts fit. Or that's what he told me, does this make sense, I thought shafts came with the new gears? Anyway, I saw several folks on Facebook recommending ProModeler servos, what do you recommend?

A6. The Savox SB-2290SG Monster is a great servo. Amongst our various competitors, they're one of the ones that give us the hardest run for the money. What he's talking about are gear shafts upon which the transmission gears spin.

These operate just like the spur gears in your rig that take power from the propulsion motor and transfer it through gears to drive the wheels. So the problem is likely the bores where the shafts fit have become egg shaped due to the forces of the crash. We reinforce the aluminum in our servos so this makes them last.

Our top competitors, like MKS and Futaba do as well. But the facts are, everybody doesn't. This is what you're paying for when you're shopping *good* servos. Ones that because they're reinforced can be rebuilt versus servos that may turn out to be one and done. Heads up!

- Savox 2290 upper gear case alongside a reinforced ProModeler upper for comparison

So what happens is when the servo's gears break, the forces of the impact don't just clobber the gears, but *also* is transmitted into the gear shafts (called this, logically enough, because they're what support the gears).

The Savox, while costing about $150 and outputting stunning torque levels leaves us an opening in the market in leaving out the hardpoints. So we're offering what we feel to be a superior servo in the same torque class and for the same money. But it's your call, as always.

Take our DS930BLHV as an example, at $130. It's in the ballpark torque and speed-wise with the Savox SB-2290SG Monster, but ours is more ruggedly built if for no other reason than because the case is reinforced.

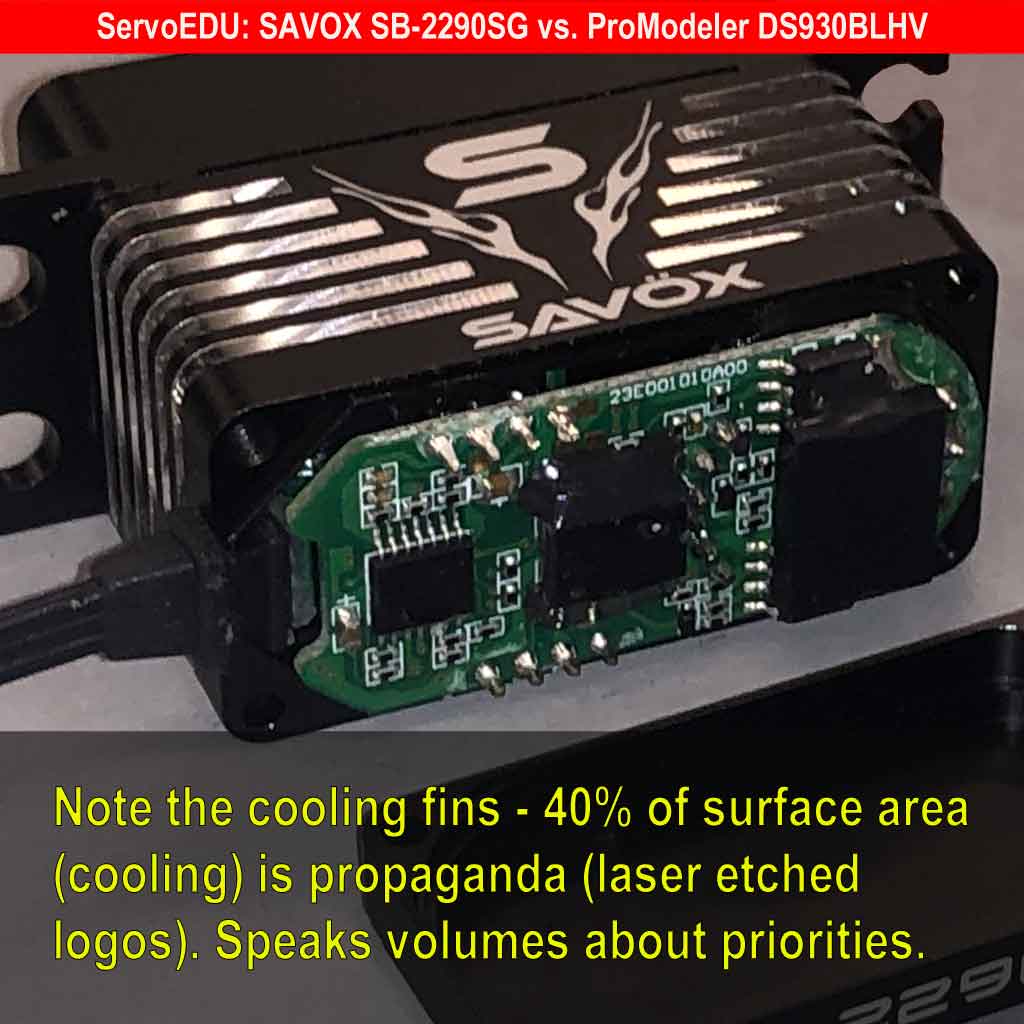

Add to it MIL-STDS and MIL-SPEC components, potting compound on the entire PCB, a top quality pot, and details like more of the case dedicated to cooling versus propaganda will absolutely come to the attention of the pros, also.

Well, here's the thing, if you're doing stupid YouTube shit, while no servo under God's heavens in unbreakable, we offer something significantly stouter if you can pony up an extra $10 over the Monster, instead.

This would be our DS1155BLHV and it's outperforms the Savox by a fair bit in both the torque (+20%) and speed department (0.10sec/60° vs 0.12sec/60°) *and* is more ruggedly built.

By this meaning the gears are significantly larger (both use steel gears, ours are stainless and are stronger not just larger), the shafts are larger diameter, it comes with a humongous spline output shaft, and this shaft bearing is larger, also. When we say more rugged, we're not kidding.

And while this next photo compares the DS845 to the 2290 and while and this servo costs $150, so the same price, outputs a bit less torque (down 13% compared to theirs), it's also a fuck-ton faster (that's a technical term I use sometimes, don't use it in front of your Mom).

So speed wise, the Savox at 0.12sec/60° is bested by the DS845 at 0.06sec/60° (a lot, remember?) which is a trade off a lot of guys will make all day long. But of course, it's your call what's more important . . . torque, speed, or money!

Direct Power Components

These are the power components that will solve the current flow problem, which incidentally, nobody tells you about until after you've bought a servo (hobby dealers work on the small bite principle). By this meaning they withhold the information you really need to make decisions without them. It's not an accident, because this way they effectively draw you in a little at a time while tying you to them and their store. Here's how it works (and yes, they hate my guts for pulling away the blinds and letting in the sunshine).

So first they sell you a strong servo (SB-2290SG for example). Then once you discover your system doesn't have the stones to run it, next they sell you an aftermarket ESC with a stronger BEC.

That's when you discover this BEC is set to 7.4V and will fry your stock radio. 'Don't you remember, I told you this!', they claim. Anyway, next they sell you an aftermarket radio system capable of 8V operation. By then you're not into a Slash for $300-400 but for more than $1000.

Seems a bit like a racket? Now you know why the aftermarket exists!

Anyway, it's our view better to educate you and leave you decide for yourself. Does this sometimes mean a guy ends up buying a Savox servo the dealer pushes instead of ours, anyway? Yup, this sometimes happen. You win some, you lose some.

For our part? We still feel an educated consumer is a better customer. So while *how* you go about deciding what's best for you is your business, for our part, we're still going to give you the lay of the land with the information you need to make a good decision. Then we'll leave it to you to wear your big boy pants and decide which servo works best for you, your use-case, and your budget, capisce?

Stones and when they're not big enough

Next, you need to know this about using high power servos - any servo, any brand - one of our DS845/1155, a Savox 2290SG Monster, or an Asian-import that amounts to an exercise in label-engineered and some fancy talking (baffle them with bullshit, remember?), e.g some new brand dreamed up by some online hobby shop guy then passing off as something more than just an el cheapo Amazon clone in drag (meaning the label their art department drew up and maybe fancy laser etchings). I mention this because there are a lot of bullshit artists selling their wares using the unknowing to praise them using online tools who as it turns out, don't actually so any engineering or design (and their stones are plenty big, but we're *supposed* to be talking about feeding servos enough current, so I digress).

- John actually working instead of yakking on the phone

Major point being, whatever servo you own, if it makes more than maybe 400-500oz-in, it REALLY need enough current flow to work at rated power. The stock BEC of your RTR Traxxas won't cut it. They output maybe 3A and you need more. Something like 10A (for real amps, not marketing's pipe dreams).

Current (A) not voltage (V)

And note; this is nothing to do with voltage, which seems confusing, but what it's 100% actually to do with is enough current . . . remember, amps (A)? Reason this is important is a 2290SG Monster? It draws more than 7A, our own DS1155? It draws 10A (more powerful and faster) so here's what you need to feed one of these things.

Either a 2S battery - like the B2S850 - or a castle Creations CC BEC PRO (which we offer).

Added to which You'll also need this HV2SV-D harness to supply the servo with 8V while the receiver continues working off the stock 6V BEC. Basically this $10 special harness divorces the two power supplies (6V and +8V coming from the battery) which is IMPORTANT because if you put 8V to the stock Traxxas radio it'll go poof and release the magic smoke! You've been warned.

Anyway, it'll be most convenient for you if you also get two of these 4" extensions because they makes it easy to make/break power (disconnect) the control power of the small dedicated battery when you're done for the day. Not essential but definitely more convenient than rooting around at the receiver itself to make the connection. Trust me, it isn't about making a $5 sale.

Last thing; if you get a servo from us, share a photo so I can add it to a Slash document This, so the next guy with a Slash has these answers I just shared with you *and* some pretty pictures!

In closing, this is a living document. Unlike a magazine article that once it's published is done, with this we can add to it. Share your questions, idea, suggestions. What hop-up parts and mods you love . . . and why! Together we can help the next guy, the fellow following in *your* footsteps intent on building his dream Slash to his vision of perfection.

--

John