ProModeler's founder is John Beech. A modeler and tinkerer who can rarely leave well enough alone. Individual servos are improved bit by bit until they're world class - by his definition - the best bang for your buck in each and every category.

Born in the Panama Canal Zone, at age 5 his parents moved stateside. Him to enter kindergarten, them seeking to improve their lot in life. From a penniless position (his mom holding down two jobs while his dad graduated with a masters in physics, University of Miami), eventually, John an

engineering graduate of the University of Alabama. He went on to found ProModeler - a company creating value by developing several dozen servos that meet eight MIL-STDS (some in the service of our government and allies).

Along the way, getting married (45 years and counting), and helping bring us a daughter into this world. Meanwhile

following his faith in God, he says . . . "I've grown up with the ultimate privilege of our nation. That of founding a business and creating value for others. But in truth, this is an ordinary story in America where we're free to improve our lot in life by dint of hard work and a spot of luck.

What's more, I see a beautiful future for America, a nation, which despite the moaning of wokesters, I don’t believe is in decline. Instead, I see us rising in ascent. We're a nation whose best

days are still ahead and I'm proud of my small part in the story.”

He continues, "I've been an RC modeler since 1972. Following a crash of

my favorite model due to switch failure, I added a 2nd lead to a battery

pack because two switches in parallel provided redundancy. My

flying buddies immediately grasped the benefit and some asked me to build

2-lead packs for them. Word got around and before long I was getting

orders from all over the state! This led me to form ProModeler in 1983

and just like that, I was in business!

In 1993 I got a video camera and

editing equipment and formed Panache Productions. This, with a focus on providing how-to

and event videos. One day the phone rang and it was Great Planes

interested in becoming our distributor. By 1998 I had started ModelSport

video magazine, and in 2004, I founded Audacity Models our model

helicopter company.

By 2010 the natural progression saw us expanding the ProModeler range of

products to include mufflers, blades, gyroscopes, plus servos. This basically served to vertically integrate

the helicopter product (e.g. one box, all the goodies required to go

fly). However, with professional UAS-interest in our servos, these eventually became the

tail that wagged our business-dog.

Today,

we continue offering 2-lead battery packs (because good ideas don't go out of

style), plus our helicopter (Pantera P6), and ModelSport DVDs, but our

focus is on servos. Ranging from a tiny 105oz-in sub-micro to a

mega-class servo outputting over 5000oz-in. We produce some three dozen different servo in our lineup. And due to our principle customer, our servos meet eight MIL-STDS. . . and we're pleased

to offer them to hobbyists, too.

Getting to know us

It's been said perfect is

the enemy of good. And while only God is perfect, we shoot for

perfection by relentlessly focusing on the details – no matter how

nuanced. Our goal is simple. Every single product should be

pick-of-the-litter compared to our competition.

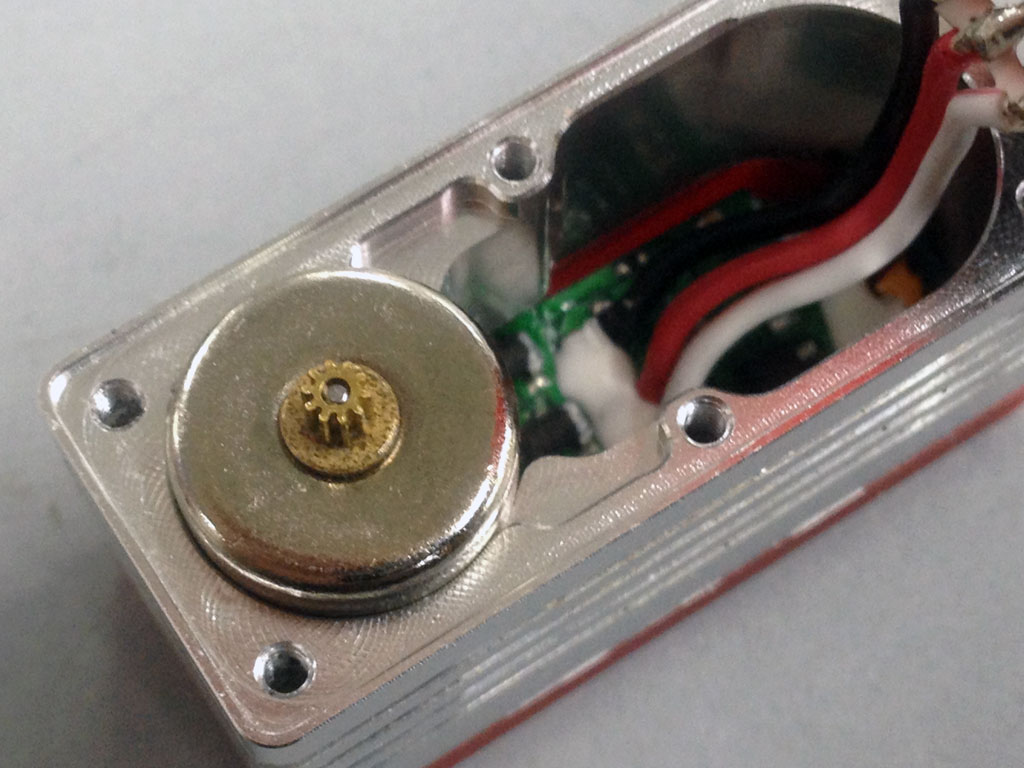

Take this $40 servo as an example, the DS180DLHV. You get a standard size servo equipped with an all-steel gear train that gives you rugged durability with a tight backlash. Using13 o-rings to seal and protect your investment from the relentlessly intrusive environment, it's earned 8 MIL-STDS. And ensuring the performance doesn't fall off due to heat, cooling is via a center that's CNC-machined from a solid billet of 6061-T6 aircraft aluminum.

None of this happens by accident. It's the result of our relentlessly process of iteratively improving every single aspect of the product. In

short, in a line up of several dozen servos ranging in price from

$30-+%00, we're proud to let this one speak for ProModeler because this

one servo defines the best bang for the buck for the market of the entire world.

Things you see, things you don't, and what to look for

We

don't operate with a 'cost be damned' attitude but anyone with

an eye for detail can instantly tell our products from the

competition. For example, we assemble our servos with 10 Allen-head

machine screws despite the fact using 4 Phillips-head screws (like

everyone else) would cost 1/4th as much. We also

use genuine Nobel potentiometers when the

other guys use el cheapo Asian-clones.

While

other are satisfied with plain plastic pockets, we fit Swiss-machined

bronze inserts to serve as hard points for the steel gear shafts. This

is how we keep the gear-train from

developing slop. If you're the type that notices details you're gonna

love our stuff. And there are other examples, like how we use a

conformal-coating on the PCB (printed circuit board) for protecting

against vibration. The other guys do nothing or make do with a piece of

foam and call it good. We also we use ABEC-9 bearings versus ordinary

(and less precise) ABEC-5. Sure, 90% of folks couldn't tell the

difference in a million years, but we know. We

could go on, but if you're a perfectionist then you should know this . .

. we share the same obsession for detail.

When engineers make decision instead of the

accountants

Bottom line? We won't say the accountants

control our competitors, but if cheap and good enough were in our

vocabulary we wouldn't be known for bespoke products.

Bottom line? If you

know of any product that matches up to one of ours and beats us, kindly let us know because we won't sleep until ours is better again!

Finally, on

the personal front, the long suffering Lynn continues to

put up with me - warts and all. And I continue flying my models,

I'm also into old cars. Add to is, I fly am antique Bonanza, which I use to visit modeling friends and

customers in an around the southeast (yes, packing a model to fly). So that's us in a nut shell.