Bottom line? It's bad ass but not unbreakable? We say this to cover our ass with car/truck guys whine like little kids having a bad day when their 40mph rigs hits a root or fence post and they think an expensive servo should have held up. Physics don't care and we're using the best possible materials so grow up. This puts you off our stuff, so be it. Don't know why but the airplane guys know not to whinge at us following a crash. So to reiterate, great servo but it's not unbreakable (just hinting at it would see some treat this as a challenge).

- So, we'll never say it's unbreakable because we're not stupid.

However, it's a very tough to beat servo in the +900oz-in class because beyond the best materials and design, we nail the price point, also. Feel free to look around because we're not shying away from anybody's product. Not even at this price point because we think this DS930 is the best in class your money can buy. Period!

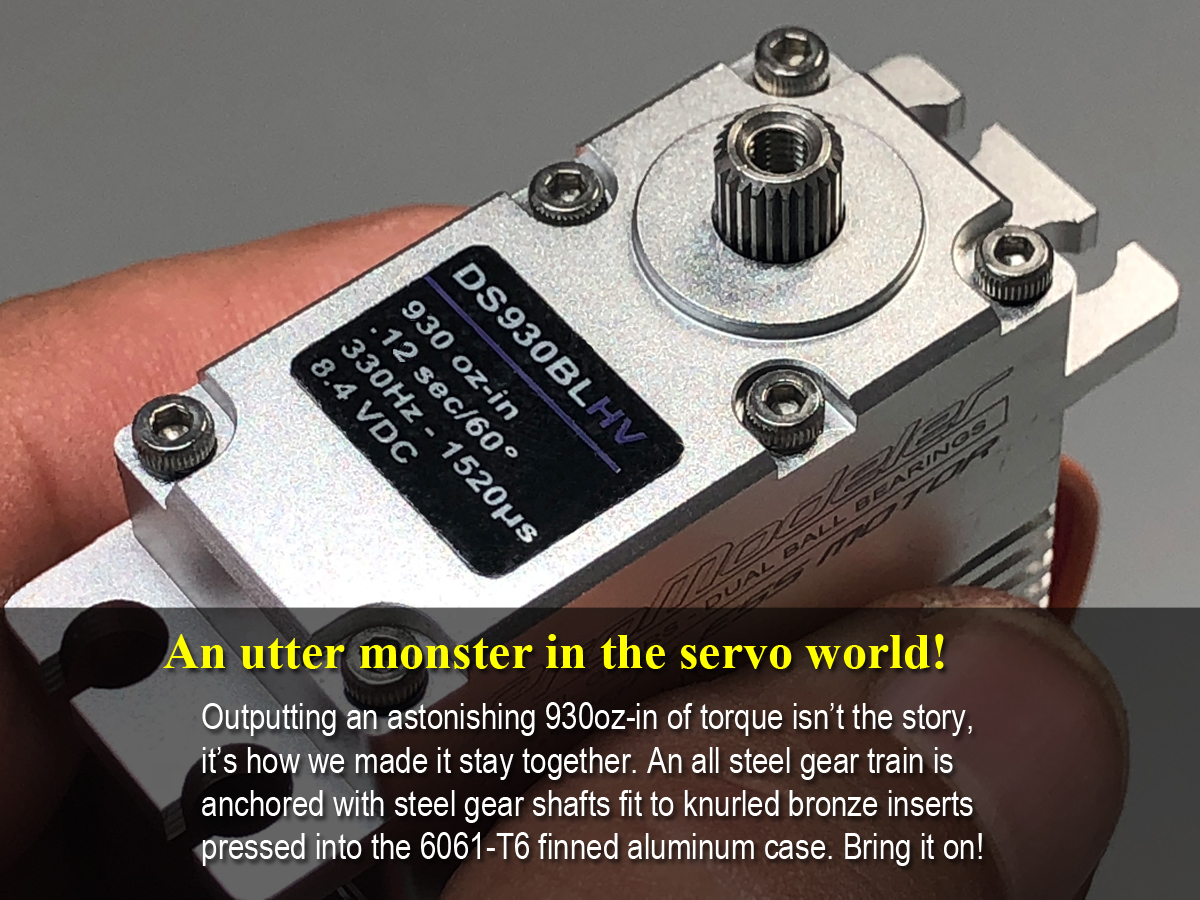

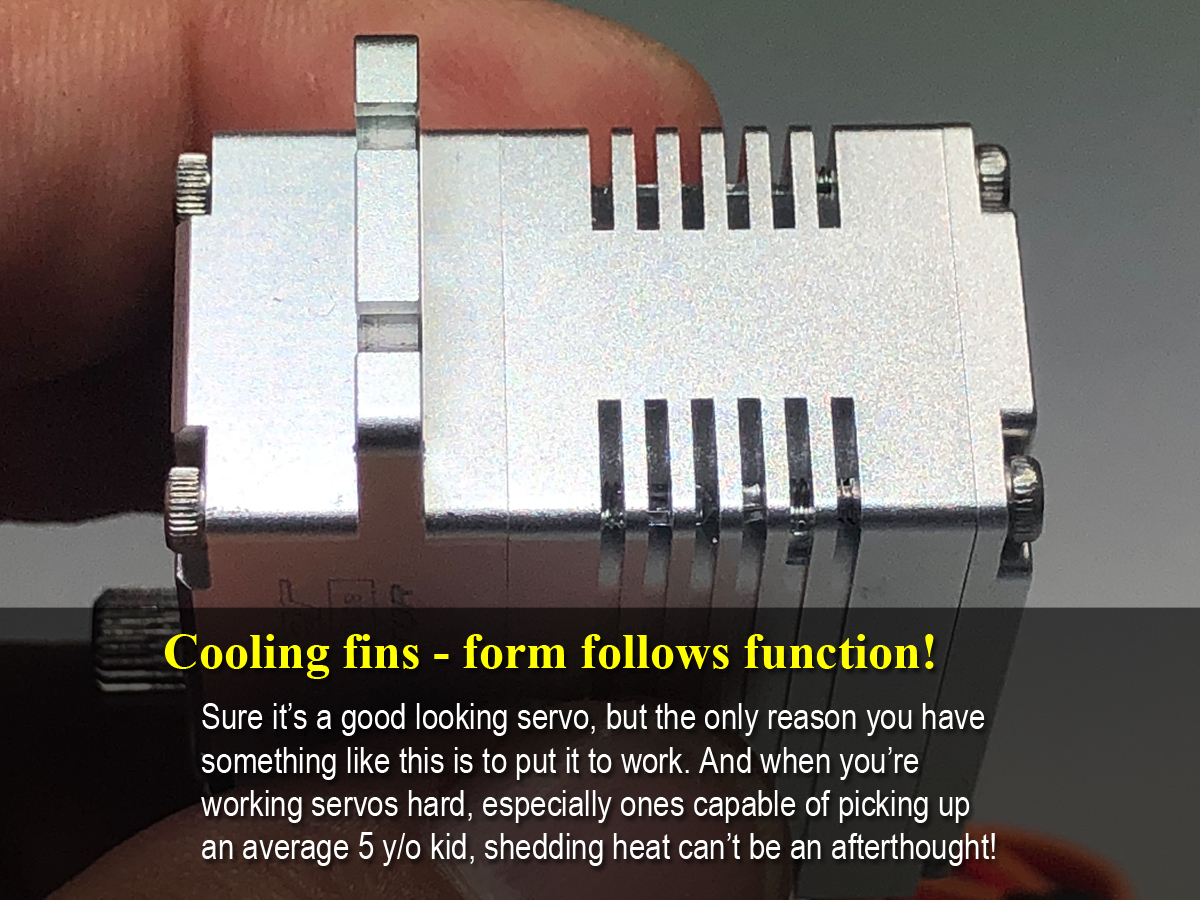

Read on to see if the DS930 fills your bill of requirements because beyond outputting a stunning 930oz-in, is very fast, and has an all-steel gear train. It's basically, a bad boy in our standard-size lineup. About 0.09' taller than the DS630BLHV, this is because it's got a longer motor (extra power has gotta comes from somewhere).

What goes into this servo includes 6061-T6 aircraft aluminum, 35NiCrMo16 steel gears, SAE 660 bronze bushings, ABEC-9 bearings, BUNA-N o-rings, DIN-912 18-8 stainless socket cap screws, brushless motor, million-cycle potentiometer, gold-plated connectors, surface-mount components, plus a conformal coating. But what you can't see or measure is an intangible because you also get our best effort and dedication - our heart and soul.

If you fly IMAC maneuvers, centering is your single-most important consideration. After all, you can't possibly fly precise maneuvers otherwise. For you, one of the principal reasons for wanting this servo are the MIL-SPEC components and genuine Nobel potentiometer. These are game changers for the sport and while we pioneered their application expressly to suit our largest customer (the one delivering ordnance on a target 8000 miles away via GPS-steering), the intense R&D required just happens to suit your needs as well. Think of it as a little lagniappe derived from your tax dollars at work!

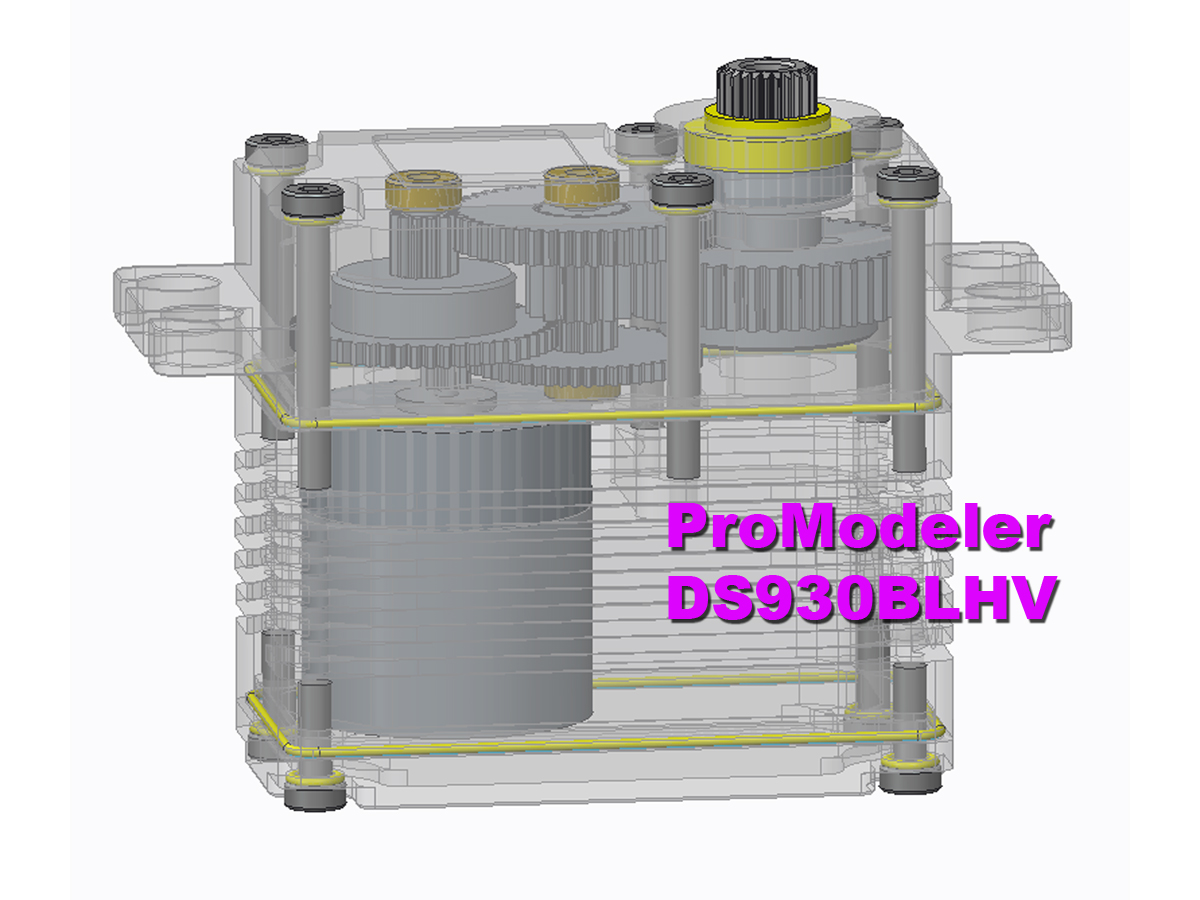

We also pay very close attention to things like making them nearly impervious to dust, water, and exhaust-oil. How? Through the use of o-rings for sealing (a total of 13 of them) plus - where the wires exit the case - a custom seal and a special 3M-adhesive. By the way, notice how the wires aren't perfectly square where they exit the case. This is because the leads are soldered to the PCB by hand (to include both left and right-handed technicians) and before the glue dries, the wires relax to their natural set and rotate a little bit before the glue sets up. As it turns out, this results in a better seal than forcing them to stay 'square' to the case so it's an instance where ignoring our inborn OCD is a good thing!

Driver information

I have to discuss things with drivers that I don't, generally, with pilots. Pilots know good and well when they tore up a servo in a crash not to come whinging to us. After all, unlike roots, curbs, and fence posts which aren't compressible, air is quite compressible so you're never gonna break the teeth off these steel gears in the air. Ain't happening!

However, drivers often include a younger demographic. Kids occasionally demonstrate behaviors in which, our grown ass customers don't engage. For example, young guy sent in this DS930 from steering his RC truck; says, 'I wasn't doing nothing but driving it up and down the street and then it wouldn't turn.' only to see this when we received it. That's a 6m steel shaft twisted like this and he claims he, 'didn't do notin' and it just happened.'

Same holds for the DS930 as the gears are very similar.

- The best steel gear money can buy aren't proof against curbs and roots

So either these customers are lying, or maybe they don't appreciate what the forces involved are when an 8-12lb vehicle kisses a curb at 25 mph, or when they launch their X-MAXX 50' and it lands on one front wheel (quite likely as they're not airplanes and have no rudder and elevator controls). Or, they're lying and trying to pull a fast one, or maybe they're just that dumb. Either way, when we receive a servo for warranty and it looks like this, we ain't paying, it's not warranty and we can fix it usually, but it's on your wallet, not ours!

Another example are gear teeth broken like this . . .

. . . and it's a steel gear! Best we can lay hands on. And no, it didn't just happen, and we're not going to warranty this kind of damage.

And if our telling you this up front is off-putting such that you'd rather buy an Asian-import servo instead, then please go ahead because we aren't in the business of paying for some knucklehead's definition of fun involving launching your rig. Tricks that raises costs for everybody else. Because that's what you're really asking us with your stupid tricks; to pass the expense on to others. No offense but we're not playing and we'd rather alienate you now than play make believe. Blunt? We're a company made up of engineers. Blunt assessment is what we do. Fairy tales are for others.

Another example is we open it and it's fried. For example, this servo dies during a 5A event. Doesn't happen just sitting there. Something bound up, wiggled wheels back and forth trying to get unstuck, or maybe an end point wasn't set properly, whatever. Ain't on us. In other words, this isn't on us to pay for the repair. Don't even try because we know our product. Don't like it? Buy an import. We don't make what you need.

Everybody else? Please keep reading because as long as we're clear, we don't offer an unbreakable product, we're good. So what's the warranty, and who pays?

Warranty: 1-year parts and labor against defect in materials or workmanship

You ship it to us, we'll fix, and ship it back. And while nothing's unbreakable, we really do try to make the best possible.

Look, our servos are built like a brick shithouse. As you read you'll learn it got a steel gear train because there's nothing better. And that said gears are supported better than popular competitors like a Savox 2290SG.

But if you ask us to warranty a breakage, it'll be clear whether you broke it, or whether under a microscope, we see an occlusion or defect in the metal in which case, we'll repair it and return it under warranty, no expense to you. But if it broke due to external forces, you pay. Clear?

What if it just doesn't work? Again, return it. We'll figure it out quickly and return a warranty repair promptly. But if you burned it up, we don't want to hear the excuses and BS. Cry online about it all you want because everybody that owns the product will recognize a cry baby because it's clear what we're making. No offense.

Where do we specifically recommend against for our DS505/630/930 Series I servos? Anything big, fast, and heavy like an KR8 or an X-MAXX where this servo is NOT recommended (we recommend the Series II servos, instead, like DS635/845/1155 or go for the big guy, the DS1885 which is specifically made for the X-MAXX). All of these are sort of bolt-ins (some plastic gets removed in an X-Maxx). But if you're experienced or a racer-type guy, e.g. into modding, then these are easy jobs. And look, we're still not saying these are unbreakable because guys can break ANYTHING, it's just that these Series II servos (and the pork belly plus all the mega-class servos) have larger gears and shafts) so they're tougher and more durable. But still, if you break it, it's still not our fault because nothing is unbreakable, capice?

Look, regarding a warranty for gear breakage. When we see deformation and fracture due to external forces that's not warranty. Damned good servo, absolutely the best steel money can buy for the gears, but not warrantied against breakage. Our 1-year warranty is for both labor and materials against defects in materials or workmanship.

Look, we've been doing this a long time, we know what we're doing. We'll always be fair but don't try to take advantage of us. Ask around.

Better components. Better servos. The formula is simple. Decisions regarding what go into ProModeler servos aren't made in accounting (where they always optimize price and profit) but by engineering where they don't give a damn what things cost because it has to suit the mission. Of course we know this servo is a little pricey, but it's because we gave engineering a free hand. Sure, hobby-grade servos may offer similar torque and speed specs . . . but the difference is in how ours are built. It's a gut level difference!

For example, marketing wondered why we didn't use titanium gears. It's sexy, they said. It's easier to sell, they said. Well, the reason has everything to do with steel having better mechanical properties for gears! Sure titanium, like carbon fiber, is sexy and easy to sell but if titanium were the be-all, end-all for gears, then in Formula 1 racing where it's very much a 'cost be damned world', they'd be using titanium gears, right? They don't for the same reason we don't, our engineers are of the opinion our steel alloy (nitrided 35NiCrMo16) is better . . . so engineering told marketing to stick it in their ear!

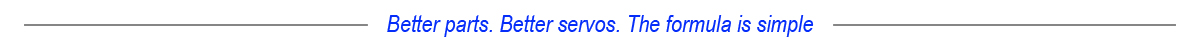

Then there was the time accounting wondered why we use pricey Swiss-machined bronze inserts (we press them into the case for reinforcement). The way it works, under the kind of loads this servo may encounter, the aluminum pockets where the steel shafts fit are pounded so hard sometimes they go egg-shape (because steel is harder than aluminum). Since these are the shafts upon which the gears themselves rotate, once that happens gear wear accelerates because the gear-mesh has gone to hell (meaning a new set of gears won't solve the problem because the case itself is deformed).

So engineering addressed the problem by reinforcing the aluminum bores with SAE 660 bronze bushings, which nobody in the hobby-business does to their aluminum servos. Granted, accounting had a point - the bushings 'are' a little expensive (and we use 3 in each servo) but it's only because they're very small parts (and thus, more difficult to handle which makes them more costly).

Ultimately, their complaint boiled down to, "Our competitors fit shafts directly into the aluminum bores!" to which we politely observed, that's because we don't build hobby-grade servos! So basically, we told them to go pound sand - but very politely because they do the paychecks!

So how strong is this servo? Well, 930 oz-in ÷ 16 oz/pound results in nearly 60 pounds, which is significantly about what two concrete blocks - or about as much as a 5 y/o weighs!

Final note: operating voltage range is 4.8-8.4V, but optimal performance is obtained with a 2S LiPo instead of a BEC. In part this is because we don't know of any BEC that can reliably supply the clean current our high performance servos need at the same time as the drive motor is making it's maximum demands on the propulsion battery. Moreover, even if we knew of a BEC (either incorporated into the ESC, or a stand-alone unit) whose output wasn't garbage compared to even the cheapest LiPo on the planet, our advice is still . . . you're way ahead of the game by isolating control-electronics from noisy propulsion-loads. Yes, we know this means charging two separate battery packs, and yes, we know this is more trouble, but a dedicated battery for the radio is better. More here: The case against synthetic voltage Resources

For detailed specifications and dimension drawings, select the Specs tab above. If they match up with your requirements, then pull the trigger and add a set to your cart. You're going to love them!