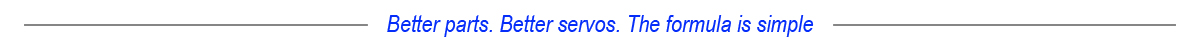

This DS210CLHV is one of 3 ProModeler hybrid-construction mini-size digital servo alternatives in the ProModeler lineup. Sharing the same hybrid construction as the DS110CLHV and DS160CLHV, this one is rated at 210oz-in, instead. Featuring the same look due to hybrid (plastic/aluminum) construction, the 110/160/210 have varying gear ratios and coreless motors resulting in sparkling performance.

Costlier alternatives in the mini-class include the all alloy minis, the 205BLHV, DS355CLHV, and DS405BLHV - more expensive due to an all-aluminum case. Anyway, outputting 210 oz-in and transiting in 0.06 sec/60°, many pilots view this DS210CLHV as our best all-arounder in the mini-class. Perhaps you will also.

Note; minis like this are ideal for 60" span 3D planes from the likes of Extreme Flight. They're also good in 80N jets and EDFs, old school 60-size pattern planes, pylon racers, 1/12th scale racers, plus 500-class helicopters.

Don't let its mini size fool you because this digital servo packs a punch. After all, 210 oz is the same as +13 lbs . . . or more than the models themselves may weigh! This means you can use them in a 89" P-51 Mustang if you're savvy enough to realize size isn't everything. Of course, a serious pilot's overriding concerns revolve around how well it centers and what it weighs, right? With respect to centering, due to our using a genuine Japanese Nobel potentiometer (the best money can buy) along with MIL-SPEC components, you get the best centering in the industry. And since the case is made of CNC-machined aircraft aluminum plus impact resistant engineering polymer (reinforced with bronze bushings at the steel gear shafts pockets), you get lust-worthy light weight plus slop-free performance that endures season after season.

Better components. Better servos. The formula is simple. Decisions regarding what go into ProModeler servos aren't made in accounting to optimize price and profit, but in engineering. The reasonable price comes about because of a better business model that eschews the old way of doing things (importer + distributor + hobby dealers). Why? it's because they all get a cut at your expense. With us you're smartly cutting out the middlemen by dealing direct so you save money while getting a better servo!

Note: operating voltage is 4.8-8.4V, but optimal performance is obtained with a 2S LiPo instead of a BEC. This is because LiPos deliver the required current without voltage spikes, noise, or otherwise adversely affecting the delicate avionics (25C or better is recommended). After all, synthetic orange colored Tang may have gone to the moon, but it doesn't compare to freshly squeezed orange juice. Same thing when it comes to feeding your avionics!

Other Resources

For detailed specifications and dimension drawings, select the Specs tab above. Also, there's an even-handed look at the competition in the Comparison tab. Meanwhile, TL;DR is chock full of nitty-gritty details so if you love delving deeply into stuff some find too tedious to read, don't overlook this tab.

Note; when the trade off between reduced torque for greater speed is attractive, eyeball our DS110CLHV because it's basically the same servo (but with different gearing). Outputting 110 oz-in at an über speedy 0.035sec/60° this servo is actually fast enough for tail rotor use - just be sure to verify your gyro supports a servo with a 1520μs neutral (most do). Anyway, aggressive 3D pilots really favor this servo.

Finally, if the thought of mini-size servos - but with brushless instead of coreless motors - are your cup of tea, our DS160BLHV and DS085BLHV (760μs) are the very top-of-the food chain. Thing is, they go for nearly 100 bucks a pop so they're not for everybody. However, with an all-aluminum case plus a brushless motor, these are our take-no-prisoners approach to a mini-size servo for those who want the very best . . . and damn the expense! You know who you are.

Note:

These are mini-size servos with very small gears and operating them manually via the servo horn may damage them. This damage is not covered by warranty. Please do not treat these like a standard size servos. You've been warned. Also, operating voltage is 4.8-8.4V, but optimal performance is obtained with a 2S LiPo instead of a BEC. This is because LiPos deliver the required current without voltage spikes, noise, or otherwise adversely affecting the delicate avionics (15C or better is recommended). After all, synthetic orange colored Tang may have gone to the moon, but it doesn't compare to freshly squeezed orange juice. Same thing when it comes to feeding your avionics!

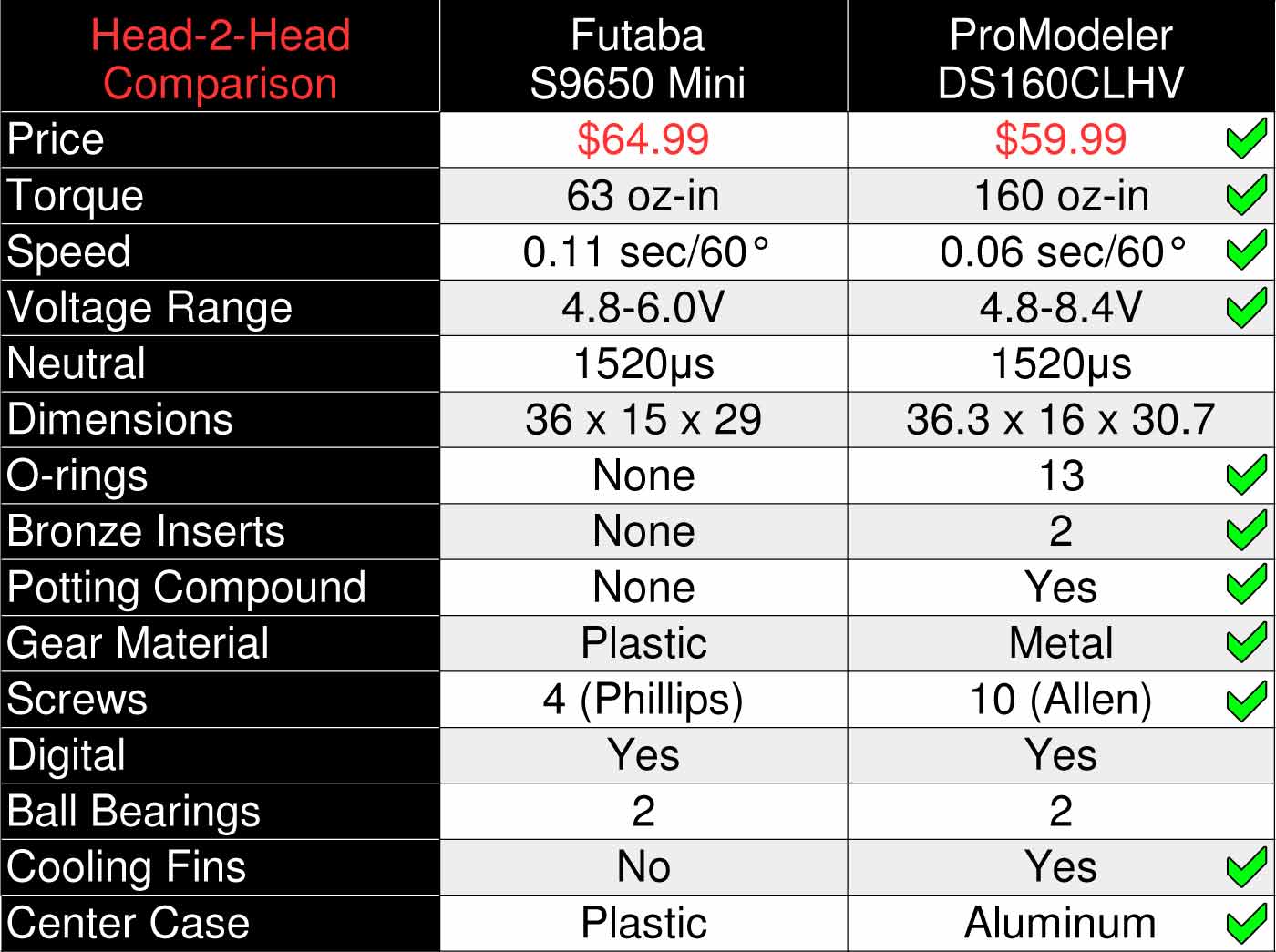

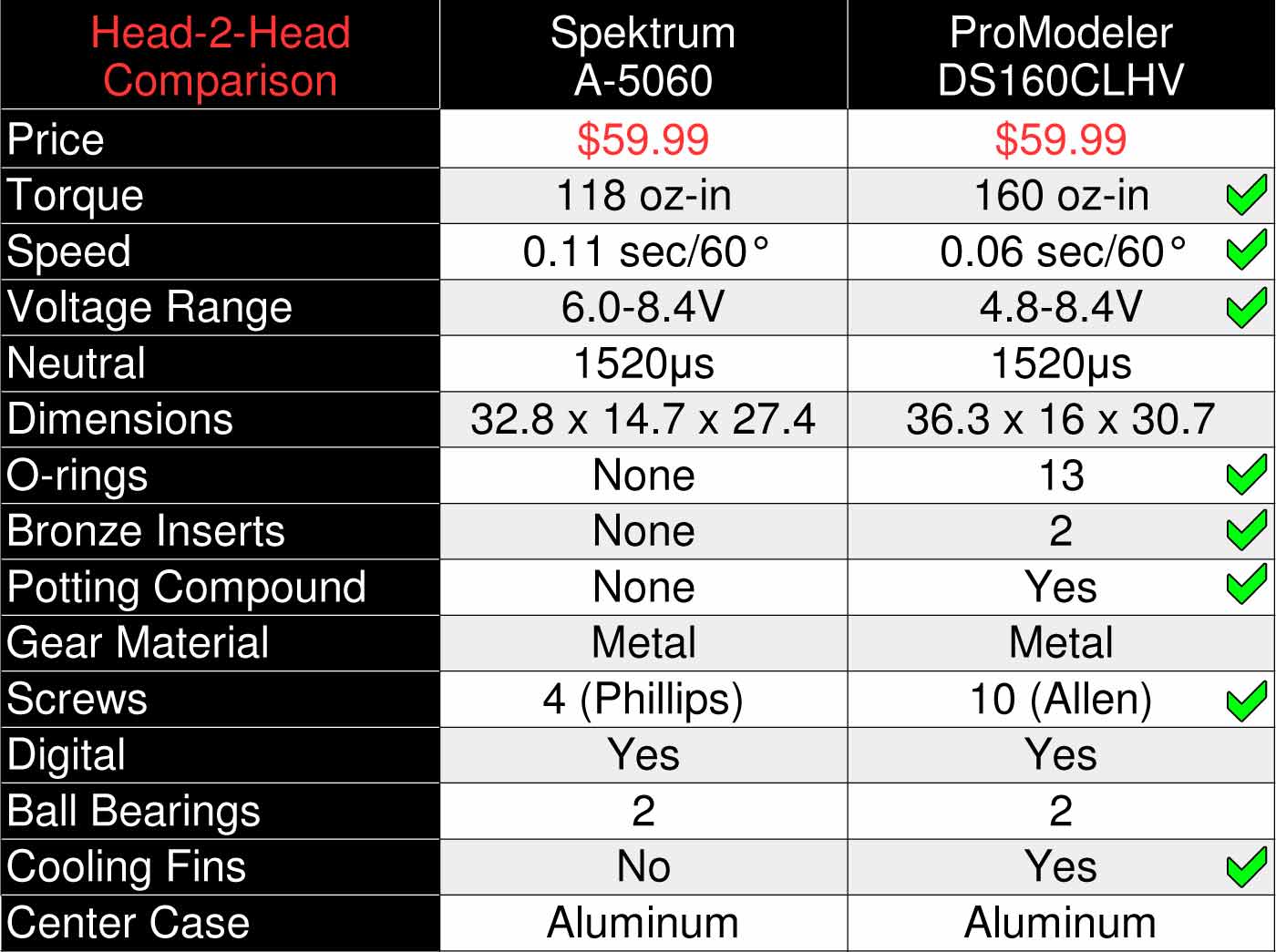

When customers mention a competing servo, they're basically asking our opinion regarding how something else compares to our DS160CLHV. What follows is a summary of our observations - offered in hopes of informing your opinion (while trusting you'll judge us to be blunt, but fair).

With so many standard size coreless-motor servos available, selecting the best one can be hard. This page compares and contrasts the ProModeler DS160CLHV digital servo with others vying for your business. While not a comprehensive market survey because we've been careful to winnow out the junk, these are ones we - as modelers - would consider buying if we weren't in the servo business ourselves (and note, despite the fact some are more or less expensive than ours, these are shown because we're not afraid of a fair fight). Servos are listed alphabetically.

- Futaba S9650 - $64.99

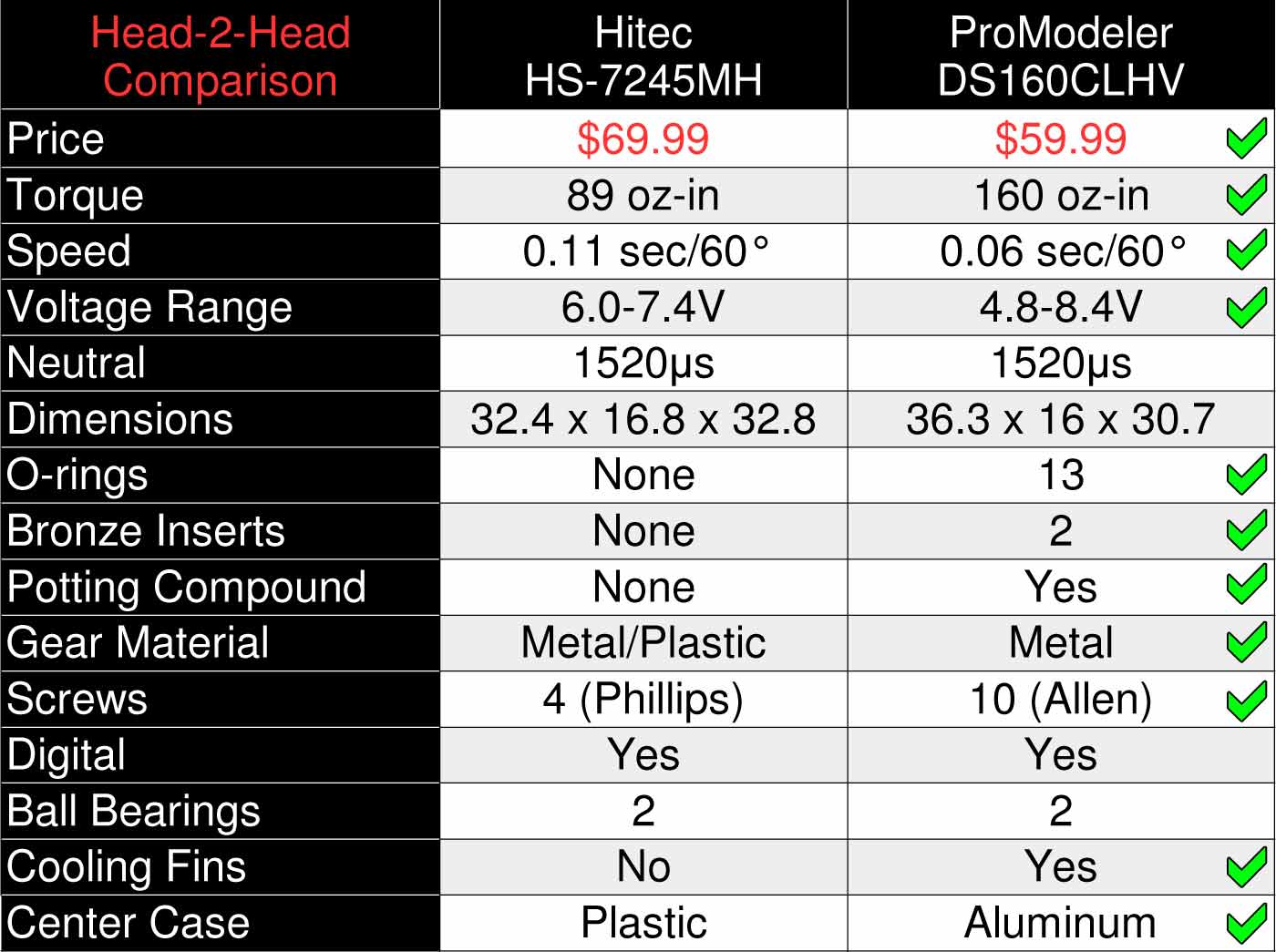

- Hitec HS-7245MH - $69.99

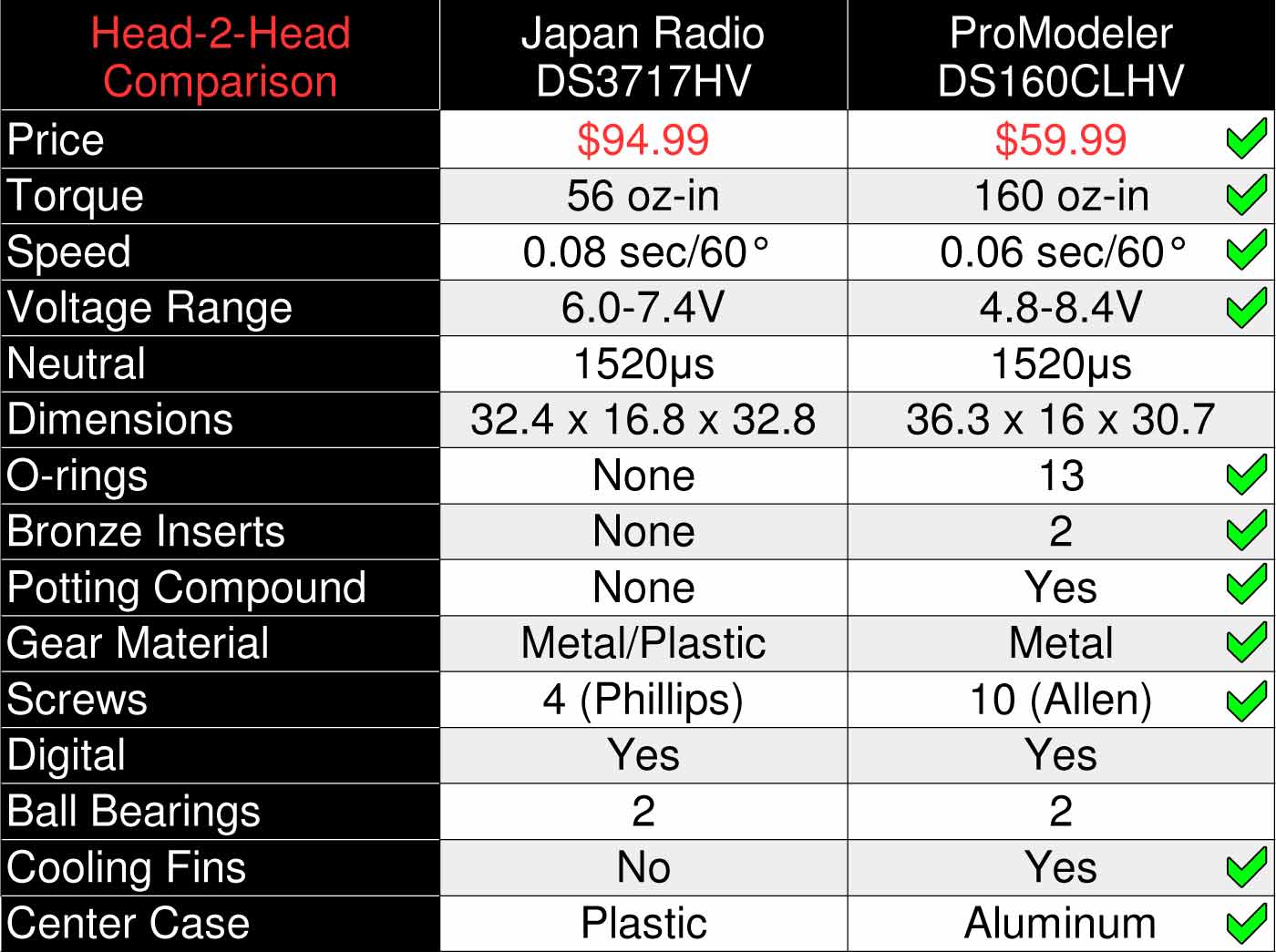

- JR DS3717HV - $94.99

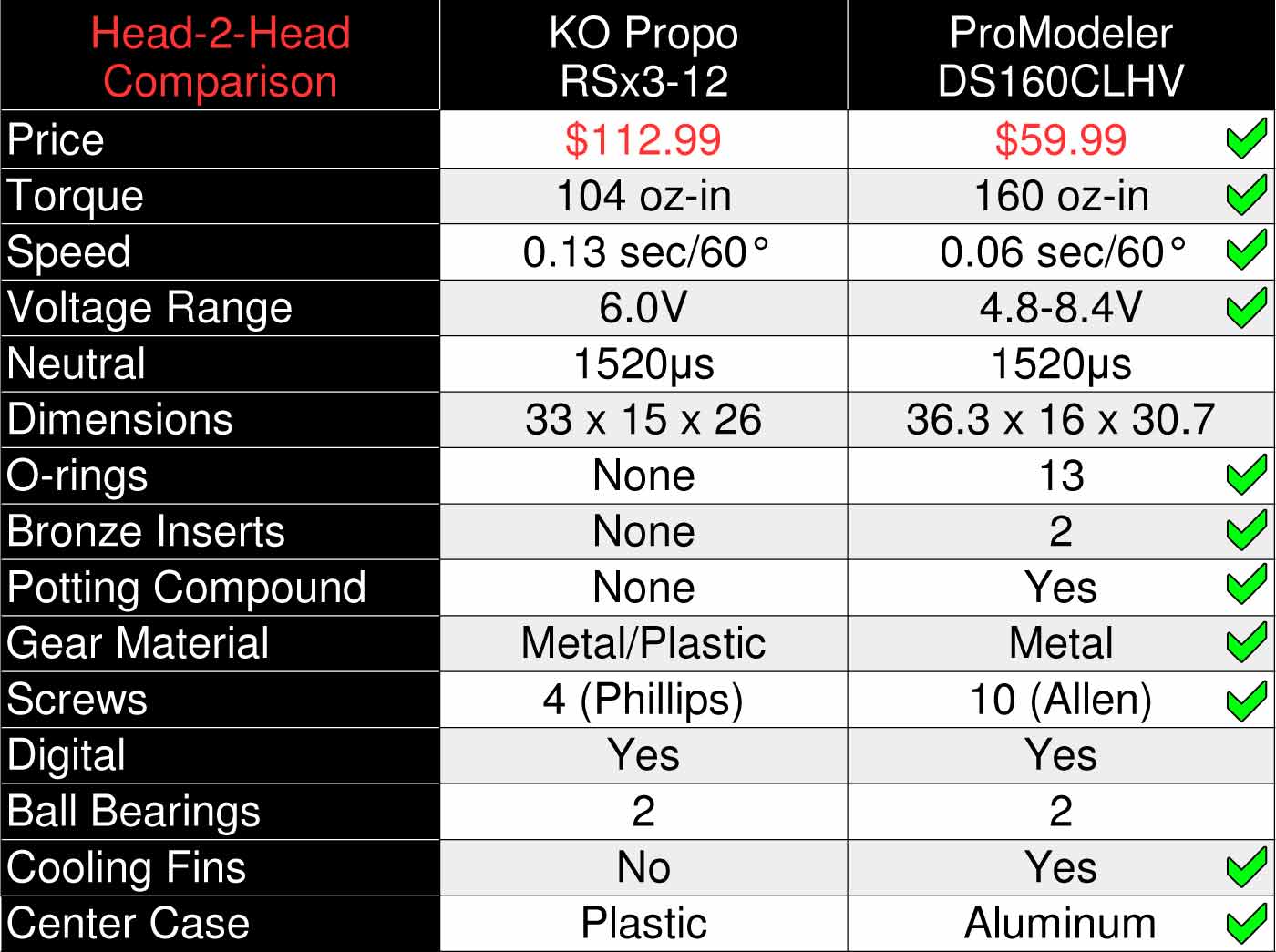

- KO Propo RSx3-12 - $112.99

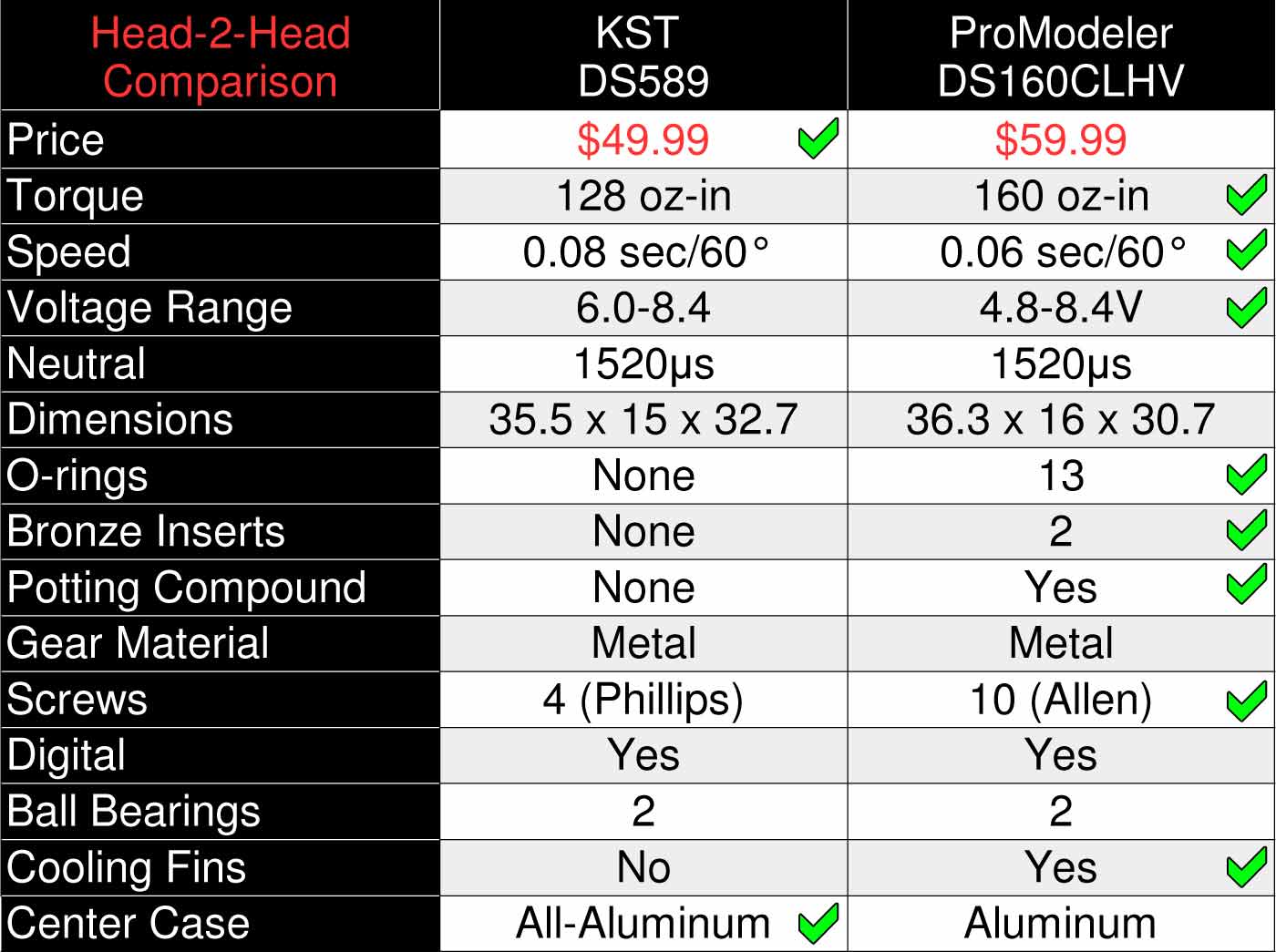

- KST DS589 - $49.99

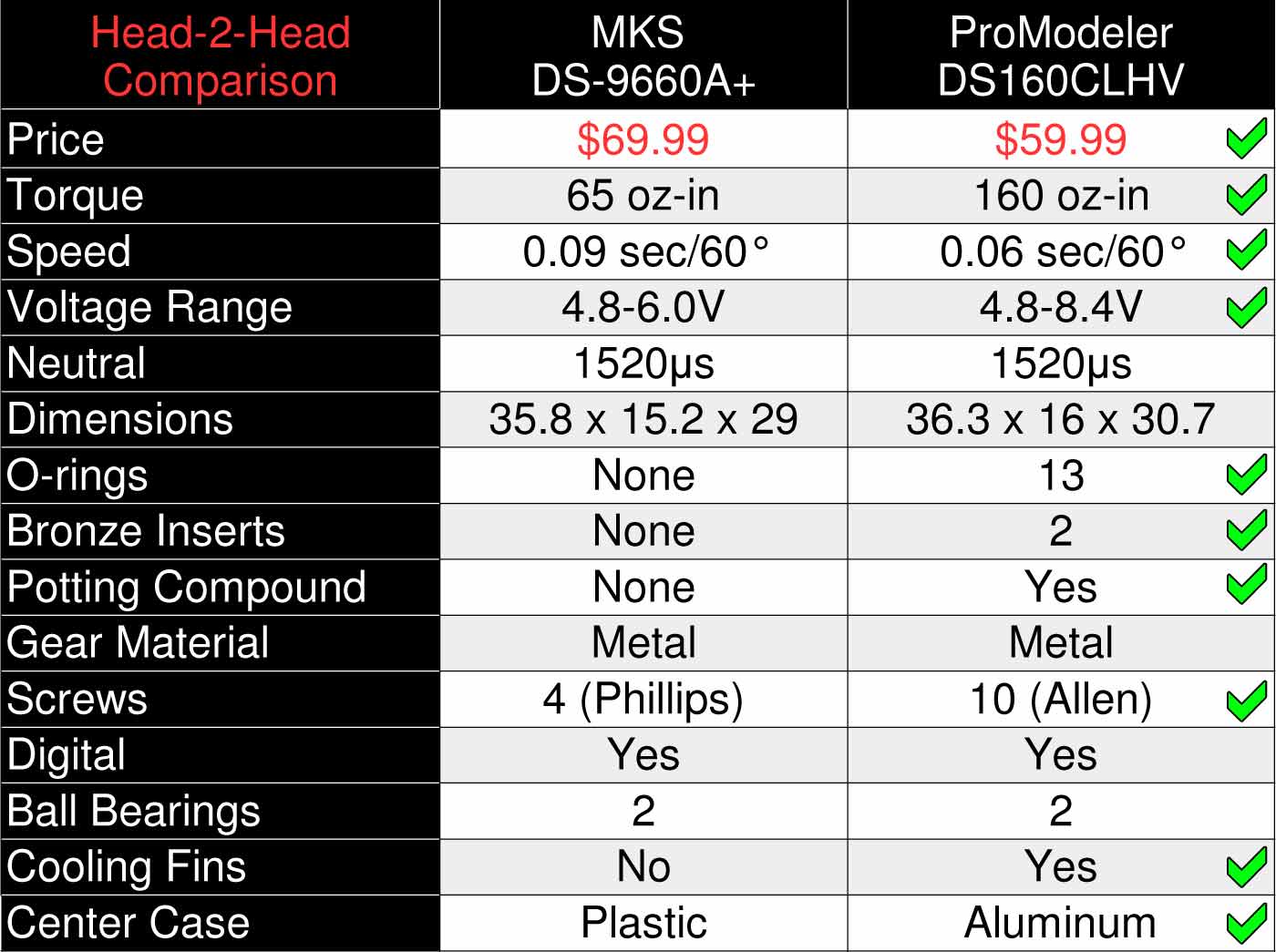

- MKS DS-9660A+ - $69.99

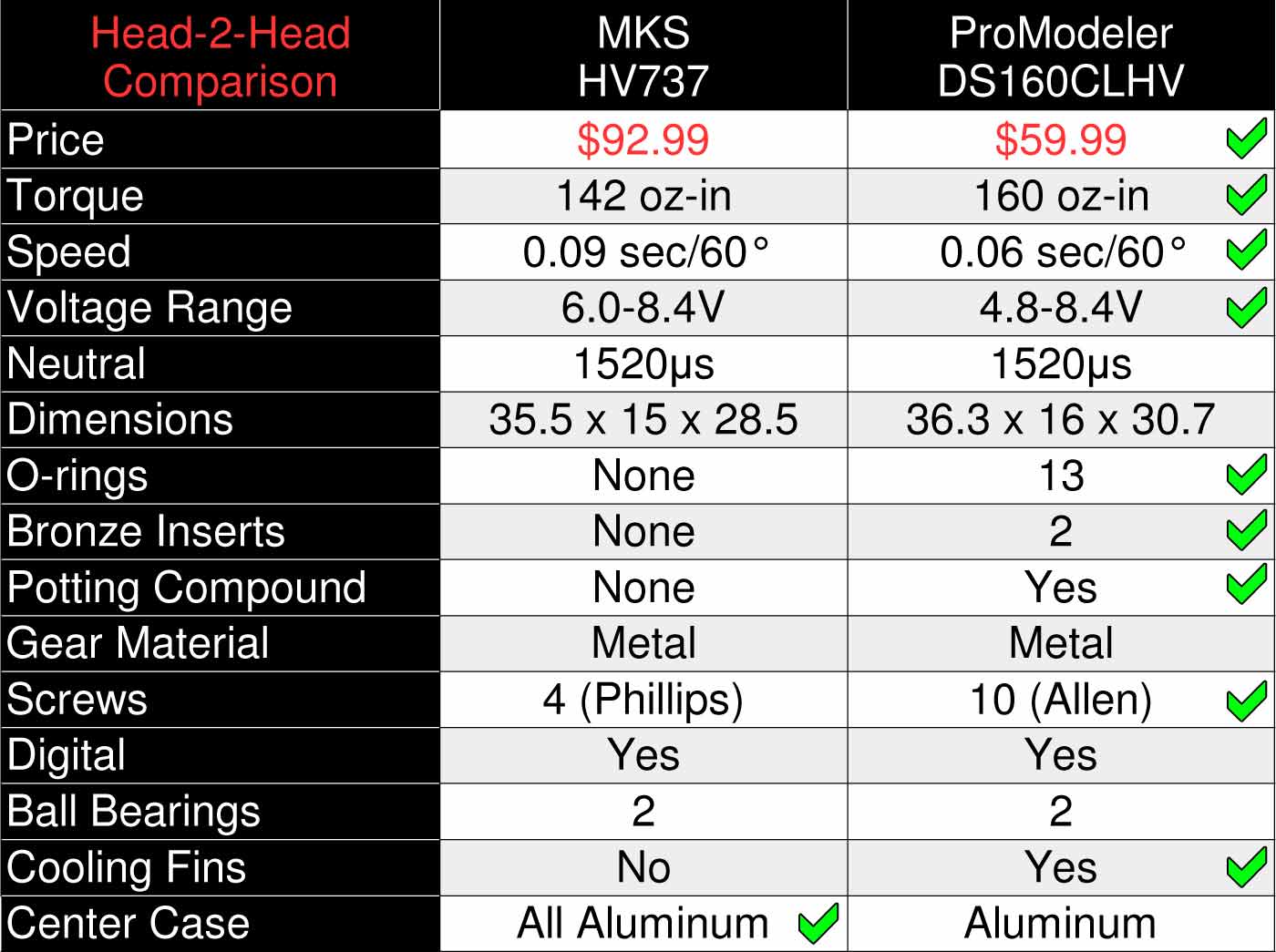

- MKS HV737 - $92.99

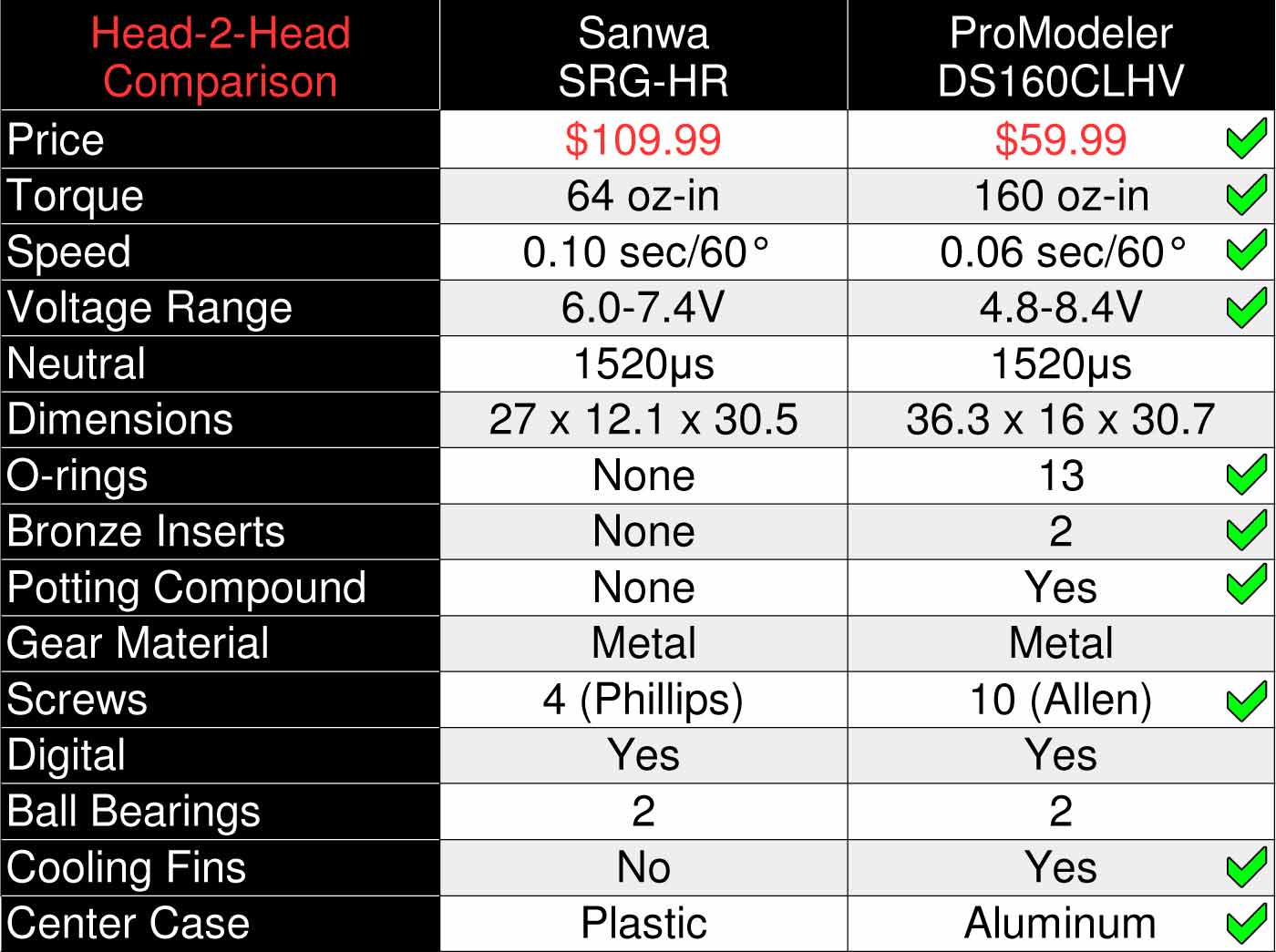

- Sanwa SRG-HR - $109.99

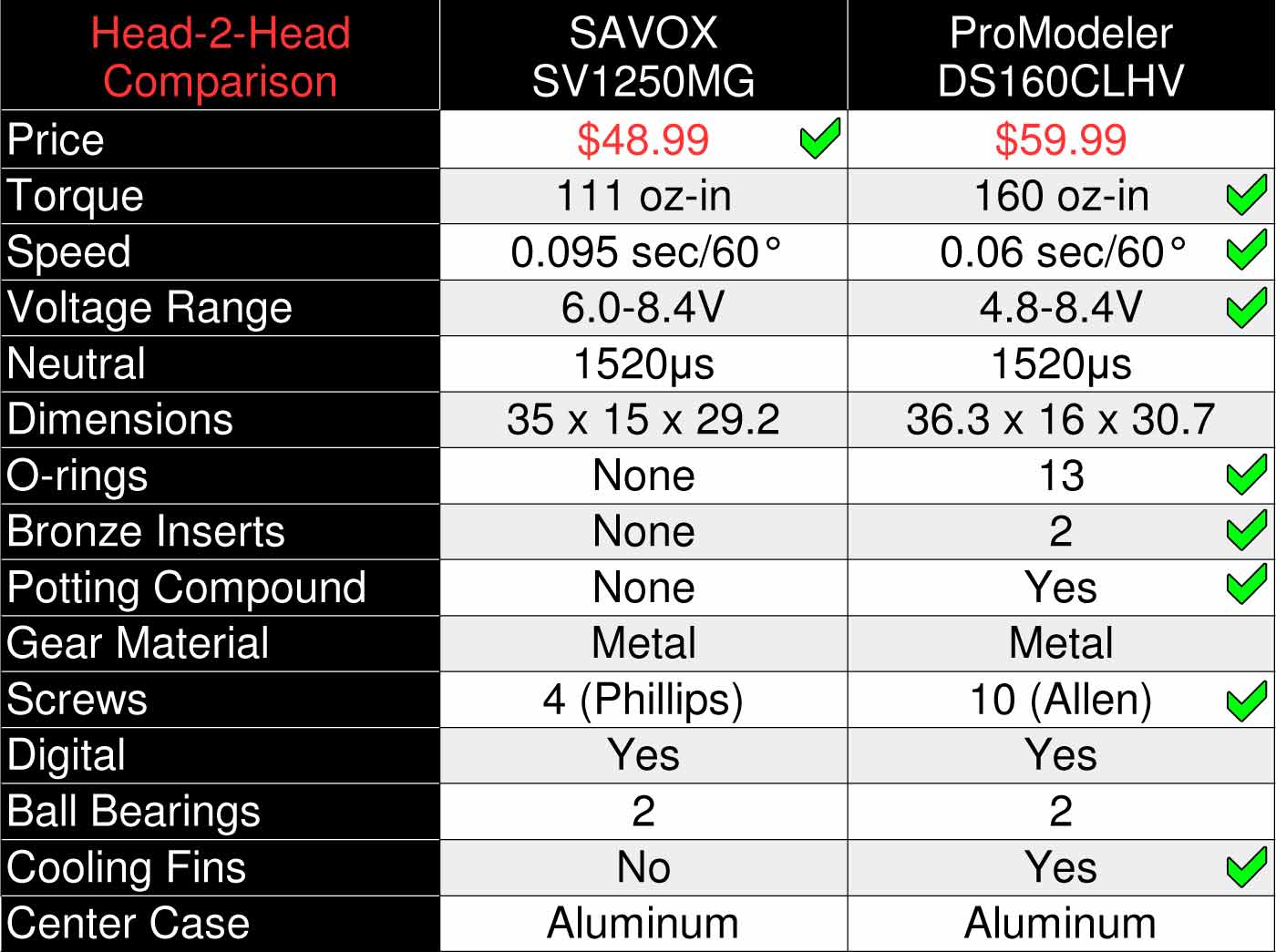

- SAVOX SV1250MG - $48.99

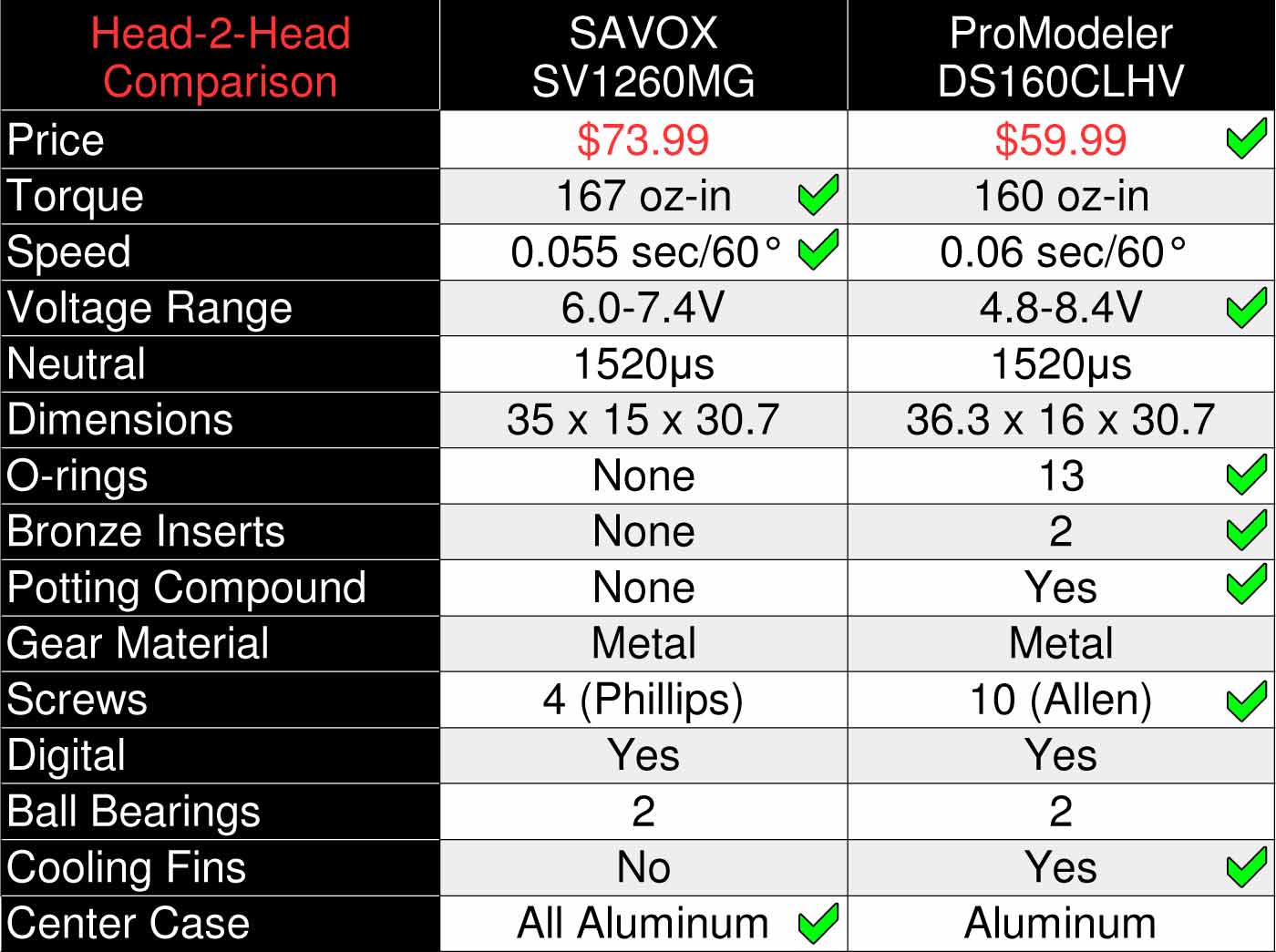

- SAVOX SV1260MG - $73.99

- Spectrum A-5060 - $59.99

First up is Futaba's venerable S9650 Mini. Our experience with Futaba-brand servos has been both long and pleasant. Especially with mini-size servos spanning back in time to when the S32H basically invented the class. The S9650 is more of the same - but digital - leading to it becoming one of the all-time best sellers in the class. However, the DS160CLHV is digital as well and handily eclipses the S9650 in both torque and speed. Moreover, ours is mechanically better too because it has bronze inserts where the steel gear shafts fit the case (so it won't get sloppy with hard use), and it's assembled with 10 bolts vs. 4 (for increased rigidity under load), plus it has a finned aluminum center-section (for better heat dissipation), as well as a PCB (printed circuit board) with a conformal coating resulting in better protection against destructive vibration, plus thirteen (13) O-rings for water resistance . . . and ours is slightly less expensive. Game over!

<

The Hitec HS-7245MH is a popular servo for good reasons. It's a solid product. However, the ProModeler DS160CLHV offers more torque, a lot more speed, and is 10 bucks cheaper to boot. Ours is also more versatile because it can be used with a wider range of voltages, and has O-rings for water resistance - important when you're dodging rain drops from a pop up rain shower one fine summer day at the flying field (or maybe enthralled by float planes and re-purposing your servos for flying a float plane off water three years from now). But what about the programmability Hitec touts? Well, with today's transmitters, reversing a servo, setting end points, etc. within the servo itself just isn't that big a deal - not like it was back in the day when transmitters were more primitive. Not that it's totally useless, but is it sufficient reason to justify buying an inferior servo? Added to which, the whole programming thing is something a moving target by which we mean, they've come out with more than one of these programmers over the years (as they evolve their software) so what guarantee do you have that your money spent for one of these things today, will still work with later generation servos? Not calling it a gimmick, but many experienced modelers believe in-servo programming simply isn't the be-all, end-all, and we concur. Moreover, with an HS-7245MH you also give up niceties like the conformal coating on the PCB (for improved vibration protection), the finned aluminum center-section (that dissipates heat better), as well as the Nobel potentiometer, plus 10-bolts vs. 4-bolts (which results in a more rigid assembly). However, even if you discount all this, then ours is 'still' better because it's more powerful, faster, and less expensive! Add one last thing, which folks bring up occasionally; when did metal gears begin to include a plastic gear? Lots of companies do this today and it seems to bother people. With respect to the HS-7245MH, the plastic gear for this servo is part #55018 and it's sold in 3-packs (for whatever that tells you). Remember this; things aren't always what they seem so be careful before reaching for your wallet.

The Hitec HS-7245MH is a popular servo for good reasons. It's a solid product. However, the ProModeler DS160CLHV offers more torque, a lot more speed, and is 10 bucks cheaper to boot. Ours is also more versatile because it can be used with a wider range of voltages, and has O-rings for water resistance - important when you're dodging rain drops from a pop up rain shower one fine summer day at the flying field (or maybe enthralled by float planes and re-purposing your servos for flying a float plane off water three years from now). But what about the programmability Hitec touts? Well, with today's transmitters, reversing a servo, setting end points, etc. within the servo itself just isn't that big a deal - not like it was back in the day when transmitters were more primitive. Not that it's totally useless, but is it sufficient reason to justify buying an inferior servo? Added to which, the whole programming thing is something a moving target by which we mean, they've come out with more than one of these programmers over the years (as they evolve their software) so what guarantee do you have that your money spent for one of these things today, will still work with later generation servos? Not calling it a gimmick, but many experienced modelers believe in-servo programming simply isn't the be-all, end-all, and we concur. Moreover, with an HS-7245MH you also give up niceties like the conformal coating on the PCB (for improved vibration protection), the finned aluminum center-section (that dissipates heat better), as well as the Nobel potentiometer, plus 10-bolts vs. 4-bolts (which results in a more rigid assembly). However, even if you discount all this, then ours is 'still' better because it's more powerful, faster, and less expensive! Add one last thing, which folks bring up occasionally; when did metal gears begin to include a plastic gear? Lots of companies do this today and it seems to bother people. With respect to the HS-7245MH, the plastic gear for this servo is part #55018 and it's sold in 3-packs (for whatever that tells you). Remember this; things aren't always what they seem so be careful before reaching for your wallet.

JR has been in the game a long time and their DS3717HV is quite a good servo. However it's pricey (about 50% more expensive), isn't anywhere near as powerful as the DS160CLHV, and it's significantly slower. But what bothers us a little is the metal gear train because hidden within the case is a plastic 1st gear! Moreover, with an all-plastic case, the motor doesn't cool as well as one with a finned aluminum case, so if you fly hard this becomes a consideration. Also, without the bronze reinforcements for the gear shafts, the case will wear prematurely leading to slop. Then because it's not water resistant, uses Phillips head screws, and doesn't have the protective conformal coating on the PCB, the DS3717HV is pretty much a lesser value by any conceivable measure.

KO Propo is a player in the 1/12th market for good reason, they make good stuff. Thing is, the RSx3-12 costs almost twice as much as the DS160CLHV while only offering 2/3 the torque - and it's more than 100% slower than ours! In addition, the DS160CLHV mini-class digital servo is more versatile because it can be used with a wider range of voltages. When bonus points are awarded for an all-metal gear train (yup, they claim metal gears but have a plastic one hidden inside), the thirteen (13) O-rings in ours for sealing, plus the Allen-head bolts, and an aluminum center section with cooling fins vs. an all-plastic case . . . it's game over with a resounding win in every single category!

KST is a new Chinese player in the market and the DS589 is a lovely looking product. We all know how they achieve their low pricing, but since we don't hide from anybody, here it is for your consideration. Obviously it's 10 bucks cheaper, but because our DS160CLHV is significantly more powerful (and more importantly for 3D pilots, 25% faster) we suspect despite their all-aluminum case, astute pilots (the ones placing a premium on performance over looks) will pass on the shiny case and opt for ours. However, posers for whom bling is more important than performance won't care and like a big-mouth bass hitting spinner bait, they'll go for the shiny object - it is what it is. The real question is this; if the higher performance of the DS160CLHV isn't worth an extra $10, will better cooling because of the finned center case, O-ring sealing, plus a conformal coating tilt the scale in our favor? How about the fact we use more precise ABEC-9 bearings, or that you get the genuine Japanese Nobel potentiometer within ours? Frankly, our potentiometer is the very best money can buy because we design with the idea that centering is the single most important thing of all - do you agree? If so, then these are important considerations, which make for an easy decision because there's a big difference between the price and its value - decide wisely.

The MKS DS-9660A+ is a popular choice with club pilots, but because of ever evolving 3D-maneuvers, ones requiring more torque for aggressive inputs on larger control surfaces, the mere fact it makes less than half the torque (65 oz-in vs. 160 oz-in) means its day is somewhat past for everybody who doesn't know about our servo (or is buying theirs out of habit). Torque, especially for IMAC pilots for whom precision is the be-all, end-all, is a big deal because torque is what allows for the very fine control inputs required when moving control surfaces precisely (remember, these are pilots flying their 60" class aerobatic models, really, really smoothly). And with respect to hyper aggressive 3D-pilots who want throws of 90° delivered 'right now', then because MKS DS-9660A+ is is so much slower, selecting ours becomes something of a no brainer even if ours didn't cost less. And all this before you take into account theirs has an all-plastic case (heat doesn't dissipate very well through plastic), theirs lacks the bronze inserts for reinforcing the pockets where the steel gear shafts fit (under hard use the case will develop slop sooner so don't forget to budget money for replacement parts down the road). Theirs is also lacking of the O-rings for sealing (ours has 13), and absent as well is the conformal coating we use, which results in a greater vulnerability to destructive shock and vibration. Basically, the DS160CLHV is the clear winner . . . even without a $10 savings!

The MKS HV737 is quite simply a great servo, and a lot of guys have bought it and been happy. Especially because it sports an all-aluminum case. While it's strong and smooth, what their customers probably didn't know is that ours is 33% faster, more powerful, and less expensive. Realizing this, professional pilots will probably opt for our servo despite their all-aluminum case - so we'll win our share of these sales. Thing is, club pilots by definition aren't pros, and because that's whose business we're really fighting for (there are way more club pilots than pros), then these pilots may find the allure of an all-aluminum case too sexy to resist. Thing is, if you're not a professional pilot, e.g. making decisions based solely on performance, then you should focus on the details like . . . why doesn't the HV737 have cooling fins? Aren't these important when the model is rocking and rolling and the control surfaces are horsing the model around with 90° throws and thus, the motor is getting hot and desperately needs to dissipate the heat better? Does this constitute cutting corners, and if so (especially because it's easy to see), then where else? For example, while it's hidden deep inside, the DS160CLHV uses the best potentiometer money can buy - a genuine Nobel that's Made in Japan and somewhat pricey. They don't mention it but if they used the best wouldn't they be up front about it? We wonder because we've been offered an inexpensive oriental clone of the Nobel (for 1/10th the price). This was tempting because it looks really, really similar - but testing revealed it's crap because it didn't last long enough. If it's your view centering is the single most important consideration of a high performance servo, then how do you justify using a cheapo potentiometer? Surely it's not just to make a shiny case, instead, right? This is also why we spec ABEC-9 bearings (the highest precision available) instead of ABEC-3 (and we aren't shy about telling you). Yet this is an area regarding which, competitors are silent. Anyway, we steer clear of cheaper components and by extension you will also when you select our servo. However, if your heart is set on an all-aluminum servo 'and' if your budget stretches enough to cover a 50% cost premium . . . then we believe you'd be well advised to eyeball our DS160BLHV also. Why? First, it's because we smoke them performance-wise. In fact, either of our minis is stronger 'and' faster than the MKS HV737. Second, for basically the same money as the MKS HV737, you not only get the pretty all-aluminum case but one with cooling fins! Third, the really big 'get' is a brushless motor! Thus, whether it's our DS160CLHV or top-of-the-line DS160BLHV, we kick butt with better performance 'and' features. So when it comes down it, do you settle for a pretty face, or go for what really matters, performance? If you think about it, your answer says a lot about your priorities.

Another player in the 1/12th racing market is Sanwa with their world famous SRG-HR mini-class servo. However, it's our opinion their plastic case is inferior to our aluminum/plastic combination because an all-plastic case can't dissipate heat as well. Moreover, theirs doesn't have bronze reinforcements at the servo shaft pockets meaning it will develop slop while ours is still tight, plus ours is water resistant, and all this before we discuss performance because theirs is a 'lot' slower, and it's got just half the torque! Then once you realize theirs costs almost twice as much as the DS160CLHV it becomes and decision because our servo wins every single category!

The SAVOX SV1250MG is a pretty good servo. However it uses an extruded aluminum center case, lacks cooling fins, and offers just 2/3 the torque. It's also 50% slower, isn't water resistant, and doesn't have a conformal coating on the PCB for shock and vibration protection. Similarly, it's lacking in bronze reinforcements (within the plastic case pockets where the steel gear shafts fit - meaning it'll develop slop and need a new case sooner). Anyway, while you save $a bit of money, considering everything that's missing 'and' that it delivers inferior performance, you'd be forgiven for wondering if it shouldn't be a lot cheaper! While only you can judge what saving $11 is worth in the grand scheme of things, we think opting for ours is a no-brainer!

The SAVOX SV1260MG is truly a worthy competitor to the ProModeler DS160CLHV. In fact, it's a little bit stronger and faster for a modest price premium. That said, the real question is; 'How long will it last?' and it's fair to ponder this because of what's missing. For example, the conformal coating of the DS160CLHV means you get better protection against destructive shock and vibration with ours. The cooling fins on ours are really important because they dissipate heat much better (especially important when you're flying hard because heat can lead to premature motor failure). Theirs also rely on Phillips head screws while we believe in using hardened grade 12.9 Allen-head bolts but what's really important about this is why; it's because instead of using 4 bolts we use 10 - and this makes a huge difference in how rigid the gear assembly is under hard loads. Also, our servo has has thirteen (13) O-rings for oil and water resistance, and this may well be crucial one day if a pop-up rain shower develops before you can land. And maybe that's not a big deal for you, but what if one day you wake up to float planes on the brain? If that happens, with the ProModeler servos you're locked and loaded but with theirs the future happens to you and thus, you have to buy servos yet again. Regardless, if your heart's set on an all-aluminum construction, we understand. Thing is, if you're willing to spend a little more to get theirs (and are willing to give up the rest of the goodies), then for just a few more bucks, our ProModeler DS160BLHV gives you something really important. First, you get the all-aluminum case, but ours has cooling fins. Second, you get a brushless motor, and this is very important. Ultimately, remember that old saying, 'You pays your money and you takes your choice' or put another way, pick your poison. Just remember; all that glitters isn't gold.

Last, but not least, is the Spektrum A-5060 mini-class servo. This is a great choice for most club pilots - but for exactly the same money - the DS160CLHV represents a better value. Why? To begin, the ProModeler servo is built better. How? By virtue of details like bronze inserts reinforcing the plastic case. Basically, this means theirs will have slop sooner because of case wear. Added to it, with 13 o-rings for protection against water and dust intrusion, ours is better again - especially if your interests broaden to include flying off water. Similarly, because of the conformal coating on the PCB of our servo, it makes it less vulnerable to high frequency vibration. Add bonus points to the DS160CLHV for the little touches, also like 10-bolt construction. And don't forget, our aluminum center-case has cooling fins to better dissipate destructive heat and thereby promotes longer motor life! All this, of course, before you consider ours wipes the floor with the A-5060 in the torque department while being nearly 2X as fast! Anyway, considering the price is the same . . . is this really a difficult decision?

Have we been fair, or unfair in our assessment? Have something to add? Perhaps you have a question we haven't answer. Fire away because we're here to help!

TL;DR means too long; didn't read. This is the section of the product page where we show what goes into ProModeler servos. You can the big picture by eyeballing the photos, or get down in the weeds regarding the nitty-gritty by delving deep to read every word - your choice. We offer this to inform you regarding what makes ProModeler servos better for your application and to help you decide what's really important.

Mechanical Details:

Comprised of 3 sections, the center-section of the servo is the foundation because it's where everything attaches. It's important to realize the difference between using an aluminum extrusion sandwiched between two plastic bits with 4-screws versus what we do, which is to fully CNC-machined the center-section from a solid billet of 6061-T6 aircraft aluminum. Basically, all ten (10) screws in our assembly thread into the aluminum instead of passing through it and thus, it's much more rigid. This is better. Also, because heat's the enemy of anything with electrons, note the cooling fins. Servos with extruded aluminum cases don't usually have cooling fins so bear this in mind as an easy way to identify the difference. These are important considerations if you're the type of pilot who flies hard because a stiffer assembly doesn't develop play and fins keep the motor cooler thereby extending its lifespan.

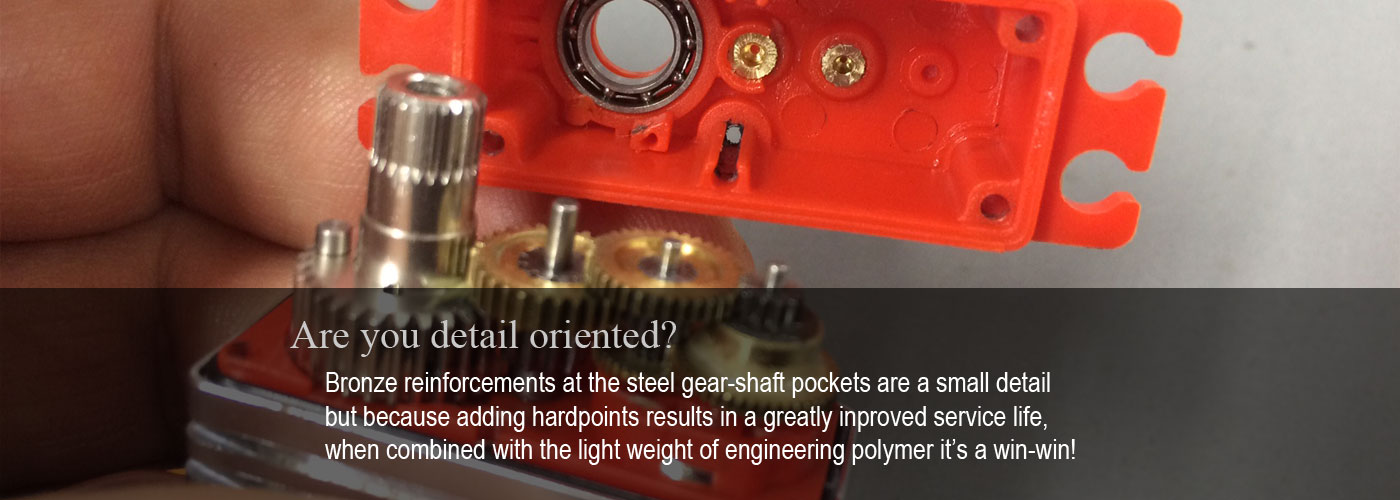

Next, in the interest of reduced weight, the upper and lower case components are injection molded of impact resistant nylon 6.6. It's not just 'plastic' but an engineering polymer like what's used in Glock handgun frames (and for the same reasons, e.g. it's tough and very durable). What makes it impact resistant are tiny fibers acting much like fiberglass cloth within the resin. At ProModeler we go one step further and further reinforced it with tiny bronze bushings. These are insert in pockets where the steel gear shafts fit so they won't go egg-shaped under stress resulting in a case that's both strong and light - and really, really durable.

Since it houses the gear train, the upper polymer case is referred to as the transmission section. It's secured to the center case with 6 screws because it delivers an 80% improvement in torsional rigidity as compared to ordinary servos with just 4 screws. Bear in mind this costs more and it's better, which is why our engineers (and folks who tend to buy the best of something and try to keep it in service forever), believe 6-screws for the upper case are a must have feature.

The mechanical assembly is water and dust resistant via captured o-rings (13 total). Captured means you can't see them once the assembly is bolted together (which also means it's harder to damage them in a crash). Riding on dual ball bearings, the output shaft of the all-metal gear train has 25T splines (making it Futaba-compatible). The lower case covers the electronics section. It's secured with an additional 4 screws (sealed with a tiny o-ring beneath each head) plus a large o-ring. An important detail we've touched on is that instead of using four (4) coarse-thread Phillips head screws, the servo is assembled with ten (10) fine thread machine screws. Moreover, there are hardened (grade 12.9) and have an Allen head (no more jabbing yourself when a Phillips screwdriver slips off). We admit these are small touches, but since we set out to build the best servos instead of the cheapest, details like these are what separates the wheat from the chaff.

To recap, better mechanical design is what differentiates ProModeler servos. Mechanical superiority is achieved through close attention to the details. Things like 10-screws vs. 4, sealing the assembly with 13 O-rings instead of none, a CNC-machined center-section instead of cheaper aluminum extrusion, Allen-head versus Phillips head screw, and especially little touches like reinforcing the plastic case with bronze hard points instead of relying on plain plastic pockets where the steel gear shafts fit. One thing is certain, if you're a detail oriented modeler, these things count.<

Electrical Details:

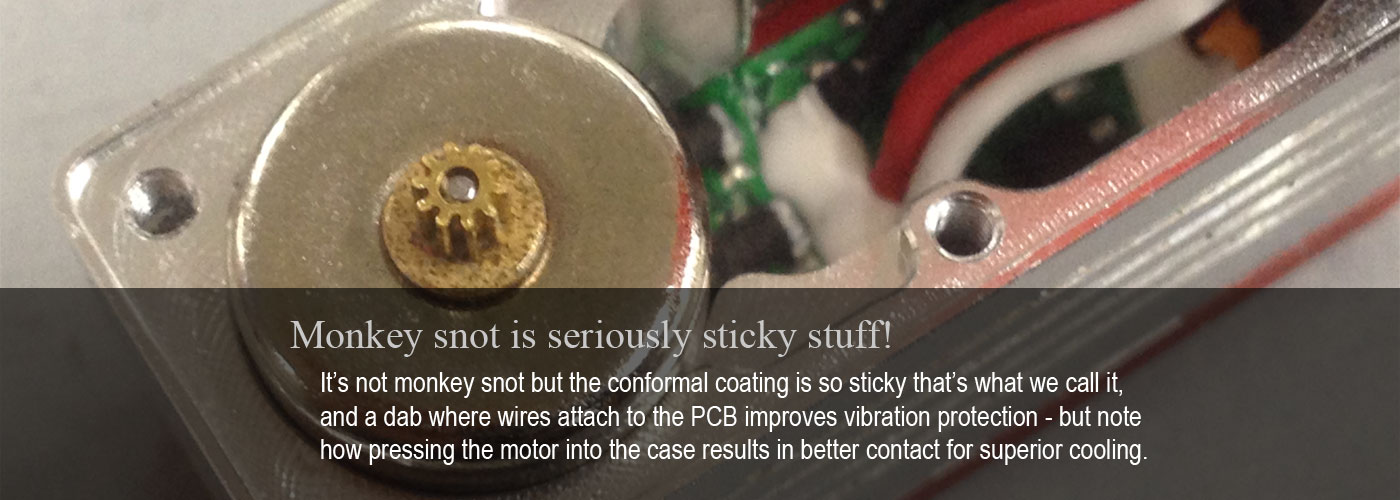

Electronic-wise, servos are pretty simple. While completely future-proofing your investment is an impossible standard, because radios are 1024 or 2048 systems, the 4096 (12-bit) core at the heart of the DS160CLHV servo offers plenty of headroom. Regarding the coreless motor, because it's lightly pressed into the aluminum center case to maximize contact area, you get the best possible heat transfer for superior cooling. Combined with cooling fins, this means the longest possible service life, which is a big deal amongst modelers in the know.

The vast majority of customers buying our products are sport modelers. Thing is, some of you may be using our servos for pylon racing or an EDF jet, which means our servos may be exposed to piston-powered propulsion (or electric motors) spinning over 30,000 RPM. These present the real possibility of destructive vibration. Here's the rub; we don't know whether you're using our product for a sport model . . . or to make a world record attempt. We're in this to make the best possible servo instead of the cheapest. This means we had to decide whether to build servos for the lowest common denominator, or to the highest possible standard. Do you take our meaning? The point is, we're really getting low in the weeds with the technical details of what goes into ProModeler servos. In part it's because we're proud of them, but in part it's because we want to inform you regarding the difference between us and the other guys.

Of course, we know everybody won't buy our servos. However, when armed with enough information, astute modelers tend to buy ProModeler servos. And those who go ahead with another product, well at least they can't argue ignorance regarding what they're not getting! Yes, it's convoluted logic, but the gist of what we're trying to do is show how we're about building the best - or nothing at all.

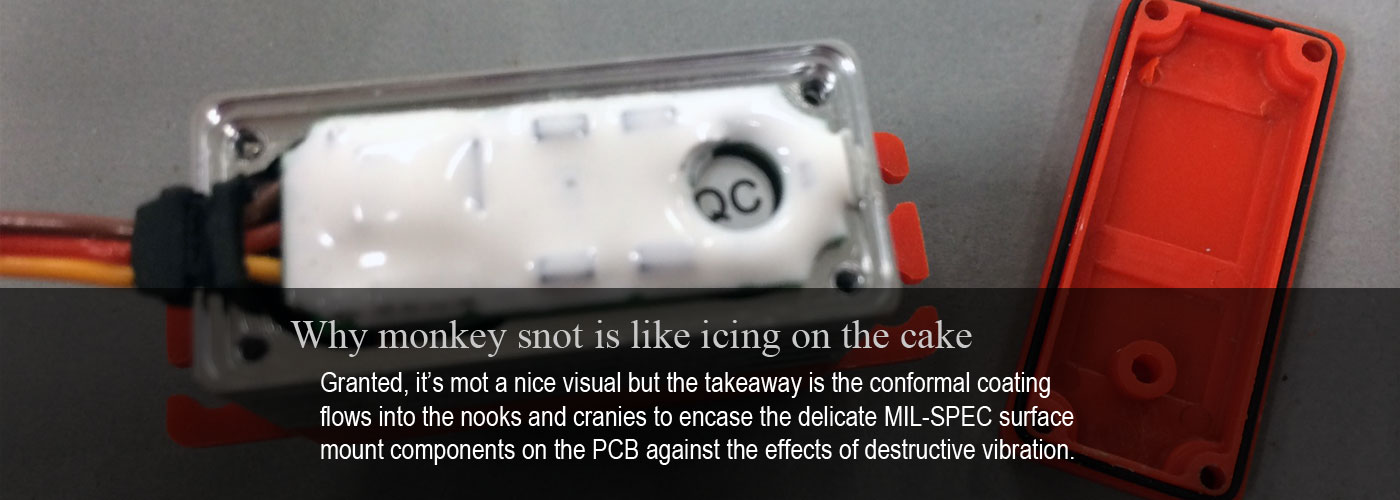

Here's an example. We use a conformal coating to protect the PCB (printed circuit board) against vibration because it flows (or conforms) to encase the delicate electronic components. Is reliability a big deal with you? We suspect the answer is yes and thus, if you can appreciate the fact monkey snot is hard to work with because it's sticky and time consuming to apply during the assembly process, then because time is money, the mere fact we use it instead of a little piece of foam to damp vibrations is tangible proof we really do go the extra mile. Ultimately, because aerospace electronics use this kind of protection, it's the gold standard at ProModeler . . . and if you're considering servos without it, tell us why. Anyway, consider yourself fully informed.

In summary, the presence of vibration protection in the form of a conformal coating is a pain in the hindquarters to apply but it's something we do because it's the best way to get the job done - not the cheapest. When considering how primary and secondary harmonics propagate throughout the model (and into servos despite the best efforts of rubber mounted mechanical isolation), you really want the delicate surface mount components fully protected by a conformal coating. By the way, when an EE (electronic engineer) calls to order servos, we often hear them mention liking the conformal coating (and stating this is reason enough to prefer our servos). Anyway, the reason you buy a ProModeler servo is because you're buying the peace of mind you get when you buy the very best. The fact it's not the most expensive means you're savvy enough to grok the difference between price and value.