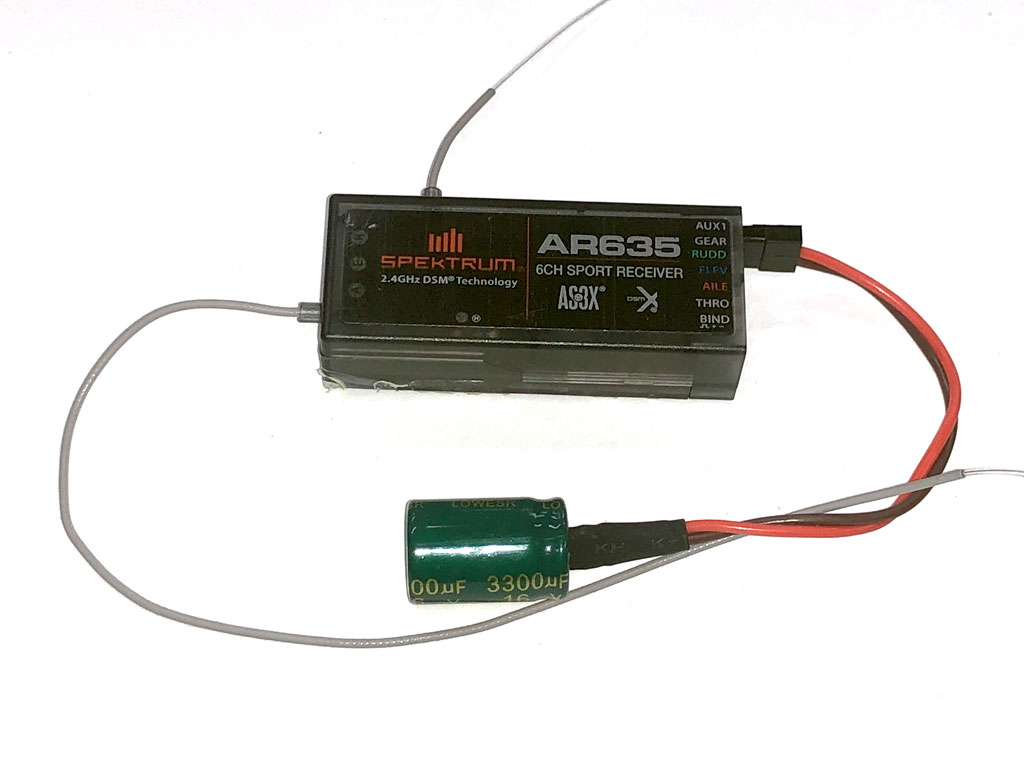

This thing is nothing but a capacitor - but - in the hobby trade they're called glitch busters. Why? Because under load some receivers will reset (brownout) leading the servo to glitch when it comes back alive. So the way the capacitor works is it gooses the receiver with enough current to keep this from happening, hence the moniker . . . glitch buster!

Caps (short for capacitors) are widely available (walk into any hobby shop, ask for a glitch buster, and they'll hand you a capacitor similar to this one).

Basically, caps solve a problem created by physics with more physics, and thus, they're brand agnostic (meaning their use applies to servos of all brands) we figure the more folks in the know, the better for the sport. An alternative to buying caps from us or a hobby shop is to order them in bulk off Amazon (or DigiKey). Them, along with some servo leads, and it's an easy DIY to solder up your own! All you have to do is;

- ensure the ones you buy are low ESR (else they're not fast enough), and

- make certain to solder the black lead to the negative (-) terminal of the capacitor

- The red goes to the other terminal.

- A bit of heat shrink to reinforce the joint, and you're done!

Why disclose the secret sauce? Because while our deal is to do with servos, we're really in the solutions business. And a capacitor resolves a problem which can rise to the level of safety. Thus, we don't just offer them very inexpensively but we disseminate knowledge regarding their use in hopes more modelers will adopt them. We think of using capacitors as best practice. Bottom line? Good business is not always about money.

So what, exactly, is a capacitor and how do they work?

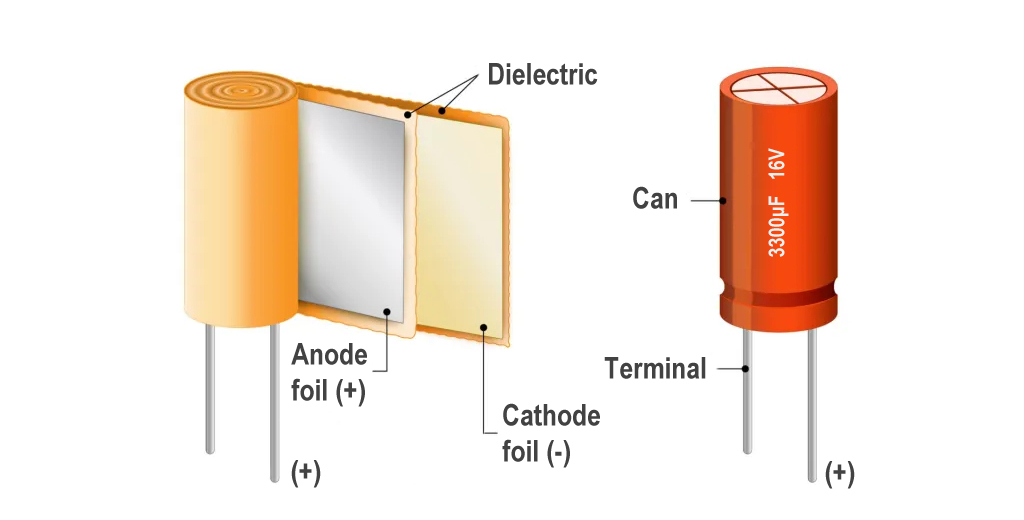

Capacitors are simple devices consisting of two electrically conductive bits of foil immersed in an electrolyte and separated by a dielectric, which is rolled up and stuffed into a small can, typically made of aluminum. Applying a voltage across the capacitor sees positively charged ions from the electrolyte accumulate on the negatively charged foil, whilst negatively charged ions accumulate on the positively charged foil.

Since the dielectric blocks charged ions from migrating, this separation of charges creates an electric field between the two foils. As modelers we take advantage of two nifty features of a cap. 1st the two bits of foil can maintain the pair of charges for a long time, and 2nd, the cap can deliver the chargevery quickly when needed. This is what they look like on the inside.

When and where do I use a capacitor, and how do I know if I need one?

These are actually 3-questions . . . so in reverse order;

- We don't have a dog in the hunt because we don't sell radio systems, so instead of telling you, we'll suggest you figure it out for yourself. How? Simple, by Googling your RF brand and the word brownout. E.g. Futaba brownout, Spektrum brownout, Jeti brownout, etc. Honestly? Complaints from 10-15 years ago aren't germane today and thus, don't really matter - but - systems with ongoing through to the present day complaints? Well, let's just say . . . heads up!

- So where do I use a cap? There are two use cases in modeling; plug in at the receiver, or added in at the load (meaning the servo). How do you add one at a servo? By using a Y-harness.

- When do I need a capacitor? The original use was RC cars and trucks. Basically, at high speed you'd cut the wheel and the vehicle would be sluggish to turn due to voltage loss under high load (physics enter this because under high current load, the voltage drops, especially true with BECs that lack the stones of a battery pack). However, nowadays, model aircraft enthusiasts are appreciating the need, also, so pretty much all modelers benefit from using capacitors to deliver a bit of juice when loads are high. More later.

Background about brownouts

If the voltage loss is enough for the receiver to brown out, then you'll almost certainly crash your model (leading folks to complain, hence the results of a Google search). With a model truck the damage is usually little to none - but - for a model airplane? It can result in catastrophic loss. A loss of perhaps thousands of dollars. Worse, there's the risk of hitting someone and causing injury!

Basically, the relatively recent adoption of HV servos by model airplane builders has led to more brownout complaints because control subsystems originally designed for servos consuming a few hundred milliamps of current are now encountering servos drawing several amps . . . each! Worse, some manufacturers haven't gotten the memo. So best practice is to add a cap at the receiver. And to be honest, if it's useful for some receivers then this means it can't hurt any receiver. Me? I use them with every receiver!

So what happens is when the load is placed far from the receiver (remember, the load in the circuit is the servo itself), so when the load is used along with a servo extension, then you also get voltage drop. In part it's just because of the extension. But also because of the load itself, e.g. the servo operating the control surface consumes current thus resulting in voltage drop. And it's worth noting, the faster the flight, or the more forcefully the surface is deflected into the air flow, then the higher the current load (meaning it needs more juice to operate) because it also means more voltage drop.

Examples

Pilots flying XA class maneuvers like Crankshafts and Rifle Rolls are definitely candidates to use caps. Why? It's because when they peg the ailerons for the Rifle Roll they're doing it at high speed and they're throwing the control surface waaaay out there into a wicked breeze and 'this' is when current draw spikes like crazy. Add to this, if you've noticed the roll rate fades as it progresses then it's probably due to insufficient current flow to maintain rated torque so the maneuver itself is telling you to add a bit of juice to the servo. But pros are one thing, what about sport pilots?

Well, ever try your hand at a Lomcovák performed maybe two mistakes high? You know, climbing line in knife edge with a bit of top rudder and carrying a bit of speed. Speed's important. Then you chop the throttle and simultaneously peg top rudder, full right aileron, and down elevator! Every model tries their hand because it's such a wild looking maneuver, so not just for pros. Anyway, performed properly your model gyrates and whips about the CG like crazy. Best part is, neutralizing the controls and the model flies out all by itself. So it's actually a pretty easy maneuver to perform. Essentially makes for a maneuver anybody can do 'if' their gear doesn't let them down.

Yes, their gear often lets them down because the ugly truth is during the period of time you're holding full control deflection the servos were drawing more current than you'd believe! And if you have problems achieving this maneuver it's almost certainly not your fault but the servos' because they weren't getting the juice they needed to operate at rated torque! Try as you might, when voltage drops off due to air speed and insufficient current flow the timing of all this becomes very, very tricky. So voltage loss is an insidious problem. And it's one affecting pilots everywhere.

In fact, even ordinary snap maneuvers, which pilots did routinely when control surfaces were normal size become especially difficult to get right when models have large control surfaces. Why? It's because snaps are power hungry consumers of current, so the voltage dips, and the combination of the servo draw and voltage loss due to long extensions make life harder than it has to be.You end up over rotating and other ugly things.

Learn more by reviewing: Thoughts on servo connectors and extension because the article delves into how to calculate the voltage loss based on the thickness of the extension wire.

Recapping; adding the high load of a powerful servo on top of the built-in voltage loss due to a long extension means your servo's performance drops due to insufficient current flow (remember, this is true for all servos, all brands, and it's 100% due to physics so this isn't a ProModeler, or Futaba, or Hitec issue, it's all servos). Added to which, using a more powerful servo makes the issue worse! So the way a capacitor helps is it discharges and gooses the load (servo), e.g. increases the delivered torque (kind of how a spotter in the gym may lend you a hand as you struggle on bench pressing a load). The capacitor is like that spotter!

So using a cap means the end of problem because it discharges when the voltage is low! Best part is a capacitor is totally transparent in operation (meaning once installed, it requires zero in the way of user intervention to activate, it just works all by itself).

So when - specifically - do you use a cap with extensions?

Basically, whenever you use an extension longer than 30" it's our opinion it's wise to add capacitance at the load (at the servo end). This, in part because the extension adds impedance as well as increasing resistance. Basically, the extension means there's less juice available to operate the servo, and this is bad juju. Allow me to reiterate, this is true for all loads to include any and every brand of servo like ours, Futaba, Savox, Hitec . . . everybody!

How do you add a capacitor - in the practical sense?

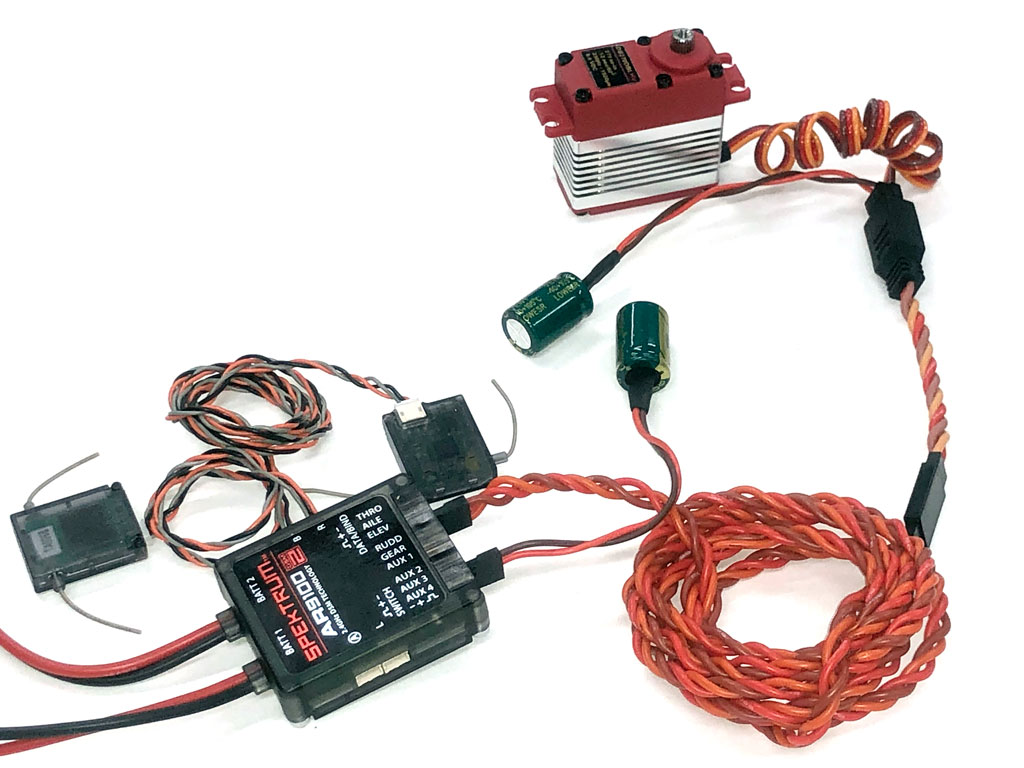

Far and away the easiest way to add capacitance is in combination with a Y-harness. Simply plug both the capacitor and the servo into the Y-harness and then plug the Y-harness into your extension. Leave it to hang loose (weighs but a few grams), or apply a spot of Goop to secure it to the air frame and Bob's your uncle!

- Cap plus load (servo) plugged into Y-harness connected to an extension from the receiver

Summarizing

In function the cap paired with the load via a Y-harness allows it to work like a power compensator. With regard to brownouts, what's actually happening is the servo's current draw temporarily exceeds the capability of the model's receiver subsystem to function in a reduced voltage environment so it needs a little bit of an added jolt. The cap does this.

Fortunately, caps are an effective solution which are cheap and easy to implement. Best part is they requires no subsequent user input, or intervention, so once you add a few capacitors to your system (one at the receiver and one at every extension longer than 30") you're done because they'll just work silently and effectively in the background.

High Voltage servos changed the game. When we moved beyond 200oz-in servos to ones ranging from 350-1000oz-in, the current demands went through the roof because power doesn't materialize out of thin air.

So now pilots and drivers justifiably concerned regarding high current draw servos, or glitches, can simply use a capacitor as cheap insurance against loss of control due to voltage draw-down during high current events leading to their receiver browning out. And whenever you're using long extensions (+30"), then adding a cap via a Y-harness is an easy way to add capacitance to overcome the added impedance and resistance of the extension. Easy peasy!

ProTip: if you're running extremely power hungry servos with an electric model (after all, high torque doesn't appear like magic) then if you're still getting weak servo response, either replace the existing ESC with a more capable external aftermarket BEC, or merely switch to using a control power battery to supply current to your model's receiver.

Finally, if you have any further questions, reach out and give us call at 407-302-3361 and we'll do our best to advise you based on your specific requirements.