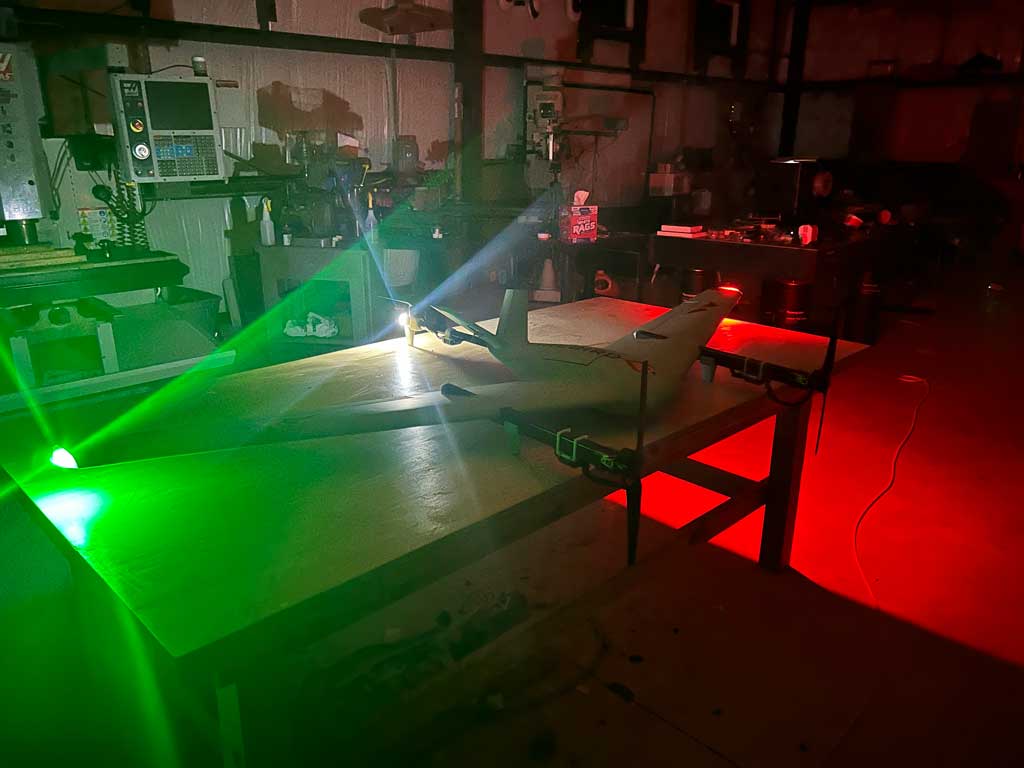

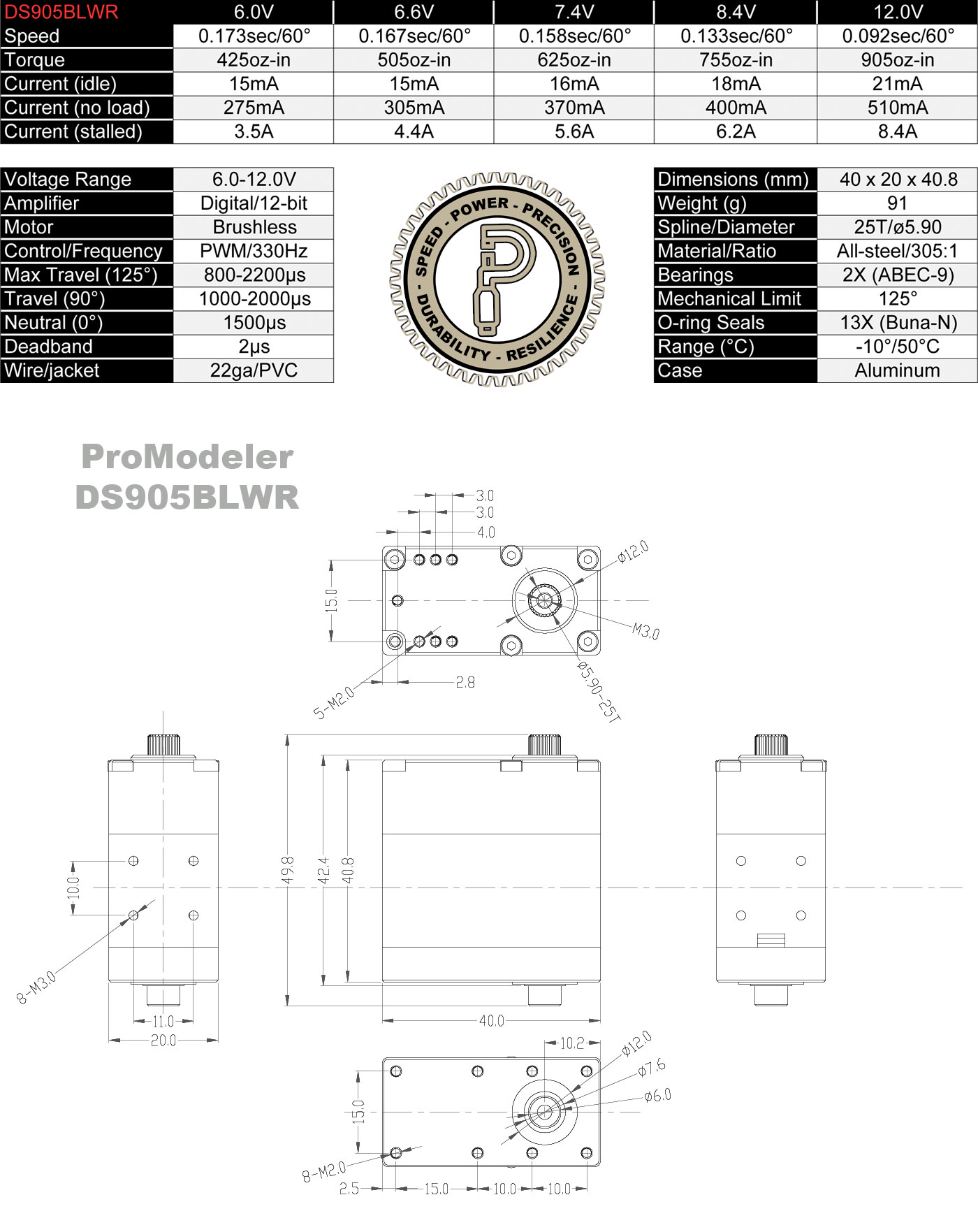

When mission value dictates a move away from inexpensively made imported tilt servos simply because failure poses too much business risk (or because mission failure if not lives on the line make you blanche), then turn with confidence to ProModeler for your military grade tilt servos. The DS905BLWR is better because it's smooth and precise, strong, rugged, and centers great . . . all whilst outputting 905oz-in (65Kg-cm).

And by rugged construction we mean things like a tough all-steel gear-train, and 6061-T6 aircraft aluminum case. This is considered a tilt servo and it's used for transitioning an electric lift/propulsion motor equipped with a propeller by 90°so as to get a lift vector, and a thrust vector from the same unit. Anyway, for the longest service life, it's equipped with a cool-running brushless motor (5X longer service life because there are no brushes to wear thus resulting in the built up of insulating brush-dust).

This dual support servo unit is offered as the ultimate solution for VTOL unmanned aerial systems (UAS), or for driving balanced brackets and joint mechanisms for robotic arms (simulating elbows, wrists, and shoulder joints when used in combination). Simply put, no detail has been overlooked. Added to which, for maximizing the versatility, it accepts a wide range of input voltages ranging 7.4-12VDC.

Bottom line? This compact dual shaft servo drive forms the foundation of a professional motion solution for the UAS industry. And to enhance its multi-role capability, we offer accessories expressly designed to make tailoring to your mission requirements easy.

Accessories include Cross-swing Beam mount, a ball-bearing supported assembly designed to facilitate tilting an outrunner motor with propeller to 24-inch diameter, the Multi-mount Beams for adding attachment points as needed, plus Drive Wheels to ease adapting to existing hardware

Cross-swing Beam mount

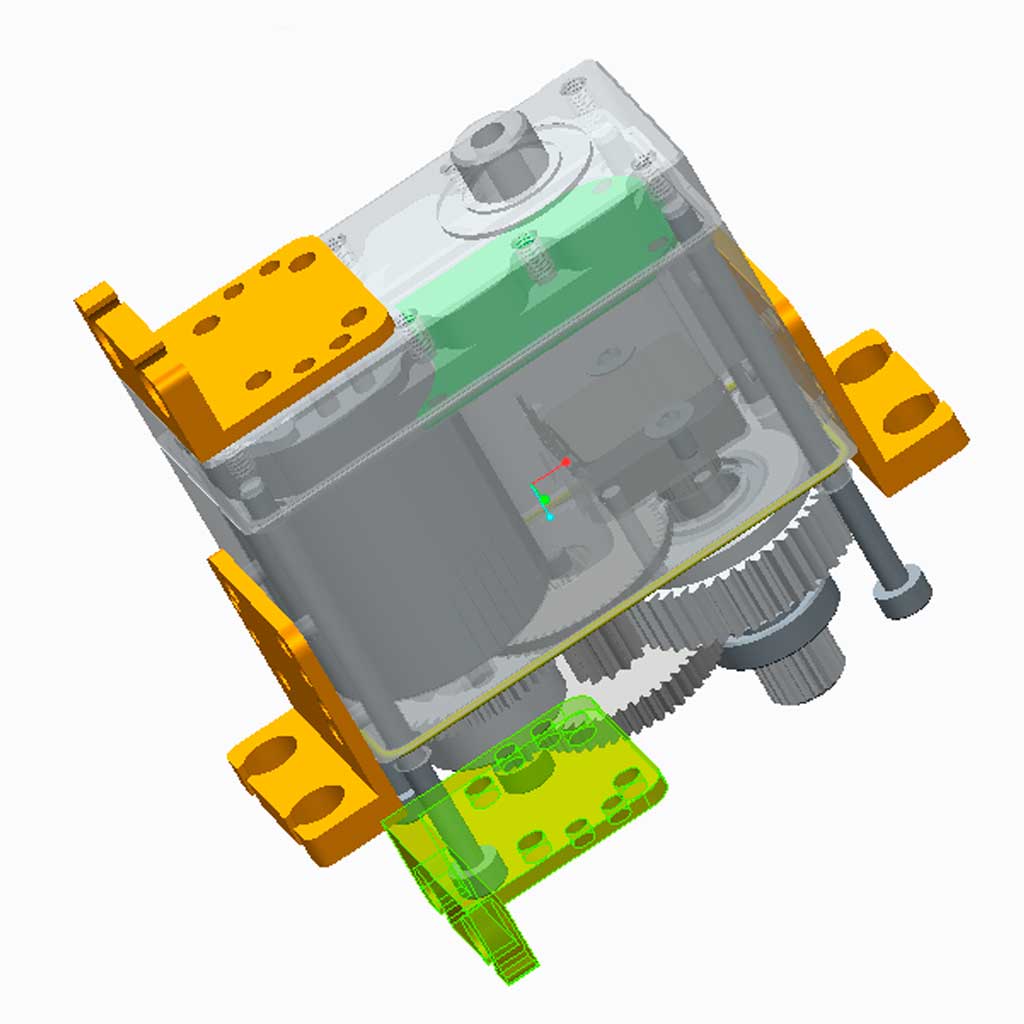

Conceptually simple, beams and wheels sets are the foundation of

making tricky adaptations. But what if you need to pivot and load, both?

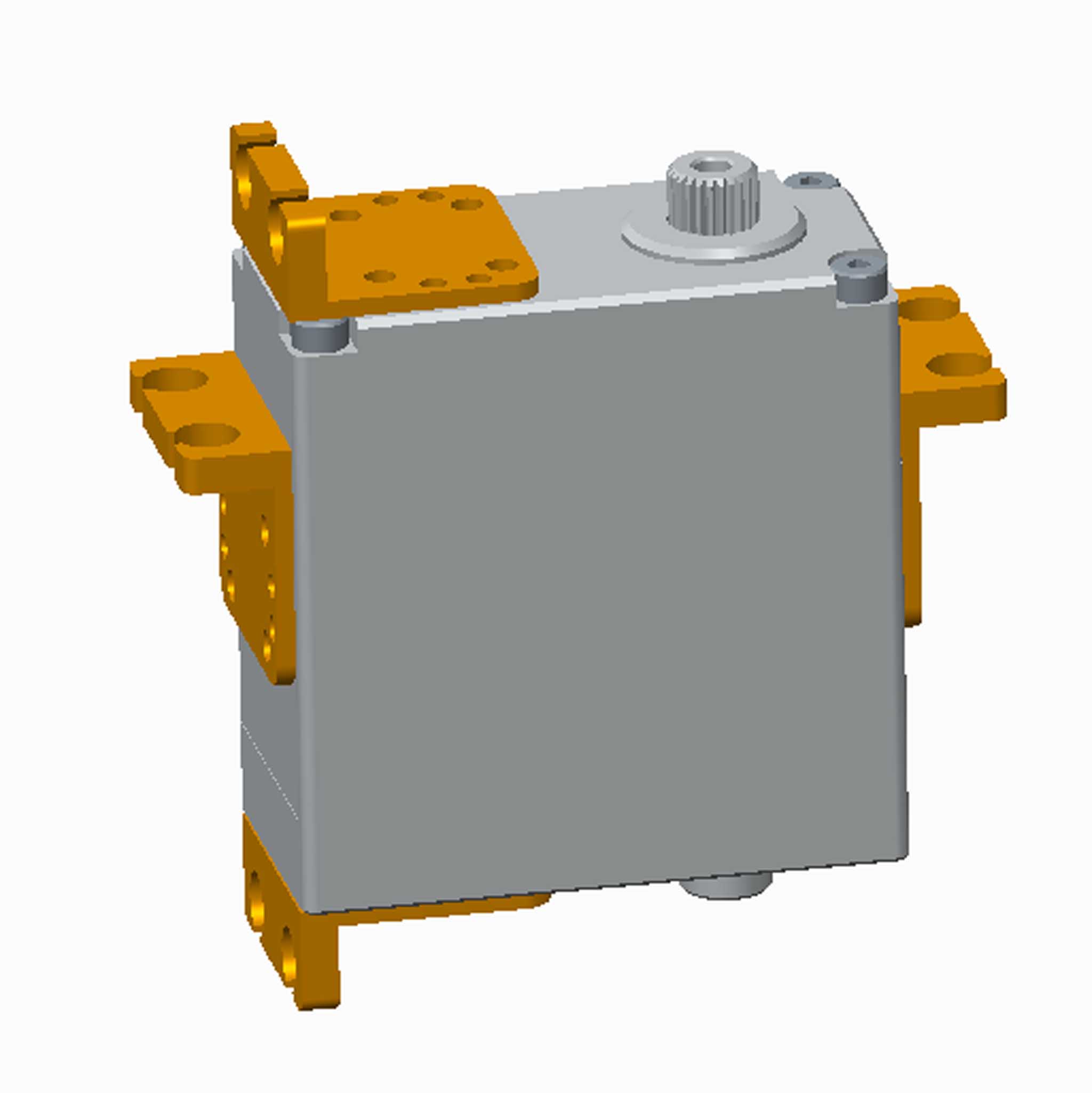

Enter the Cross-swing Beam mount, which by combining both a mount and an output arm in one,

concentrically supports the load 180°from the output. This may be one of the

most time saving accessories ever created in the motion control world.

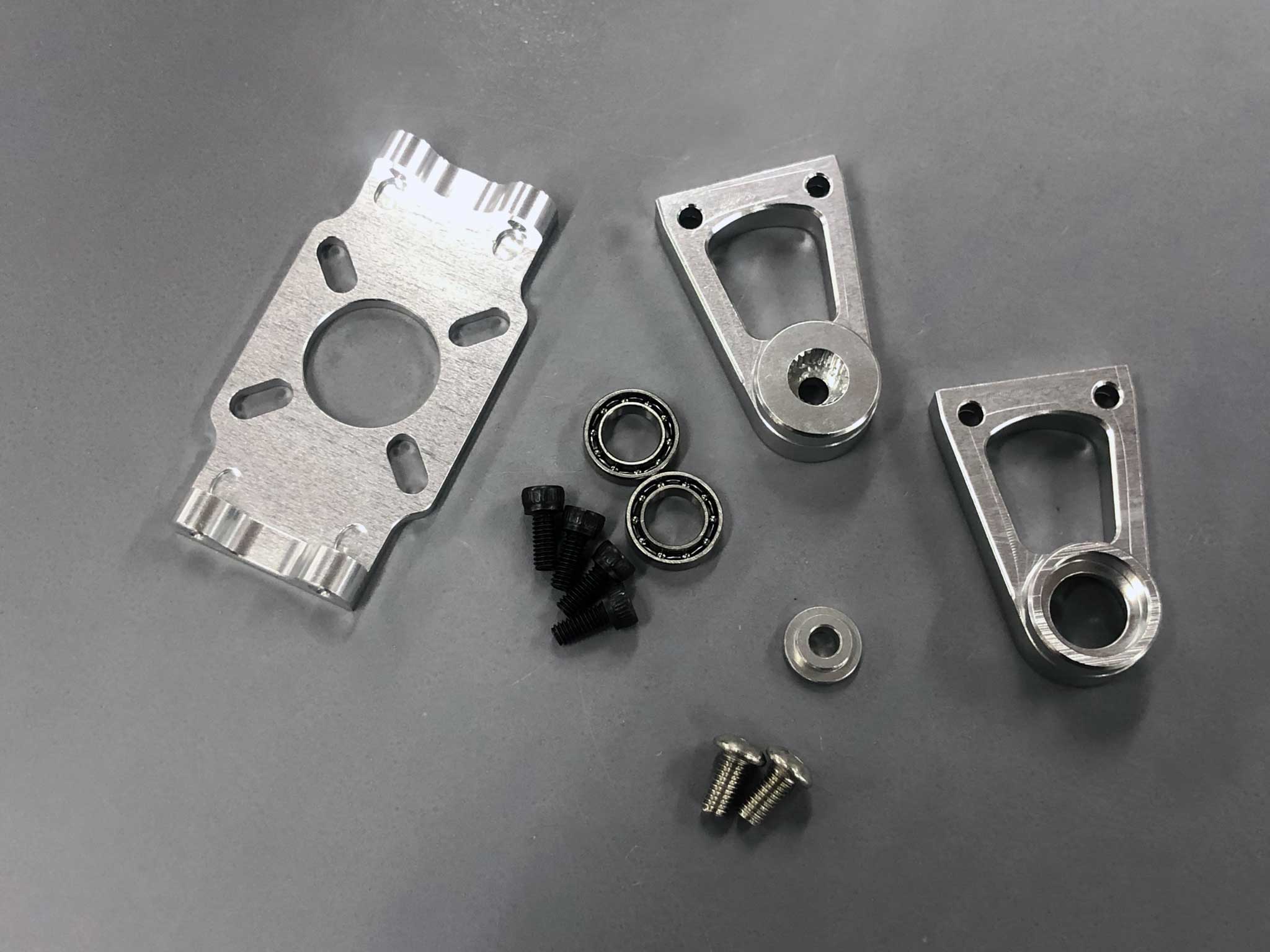

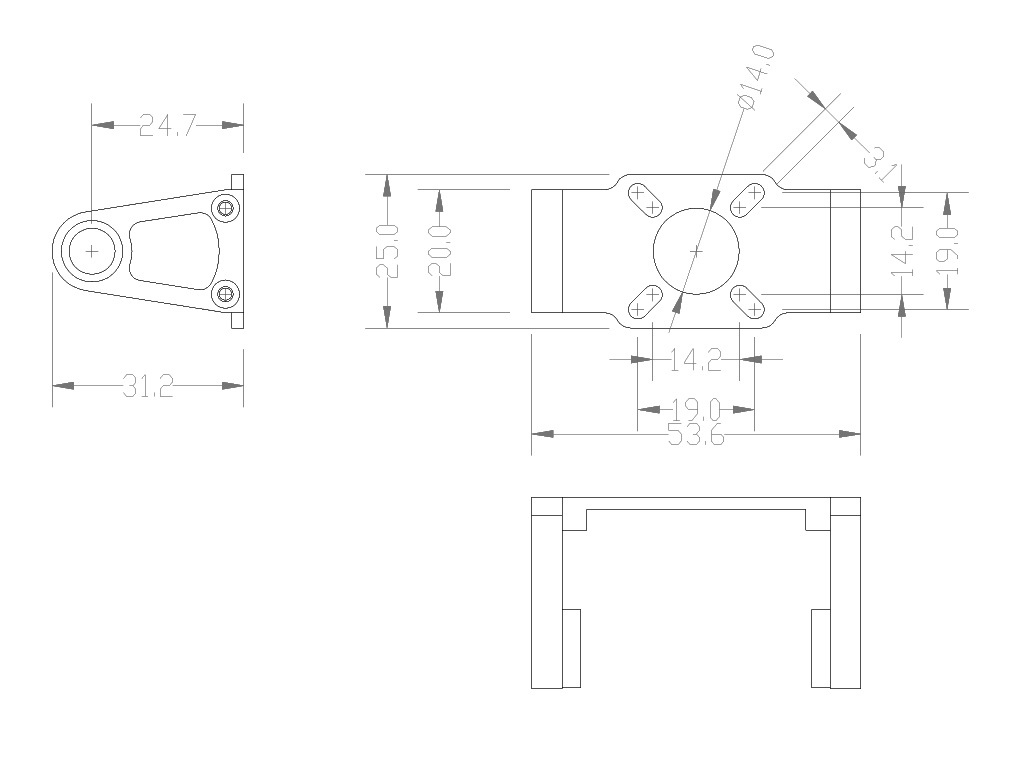

- Cross-swing Beam Mount - components

So is 'this' the best way to put this servo into harness? Well, as a

wise wag once observed . . . it depends! While Multi-mounts Beams or a set of

Drive Wheels give you a great way to grab the output of the drive unit, using a

Cross-swing Beam Mount gives you a significant head start on production because it easily bolts

together and offers you a radial-bearing supported mount

upon which your team is immediately ready to install the load . . .

easy peasy!

- Cross-swing Beam mount - assembled

Multi-mount Beams

Since it's impossible to predict the purpose to which government and industry product designers may put the DS905BLWR, we've also created the Multi-mount Beam. These nifty little accessory mounts offers a wide spectrum of possibilities for attaching a DS905BLWR to existing designs. This is aided by how the case is tapped on four sides. So whether one mount is enough, or you need a pair (or four), the purpose of this mounting beam hardware is to make the process of customizing and adapting this motion control dual shaft servo into your product just that little bit easier.

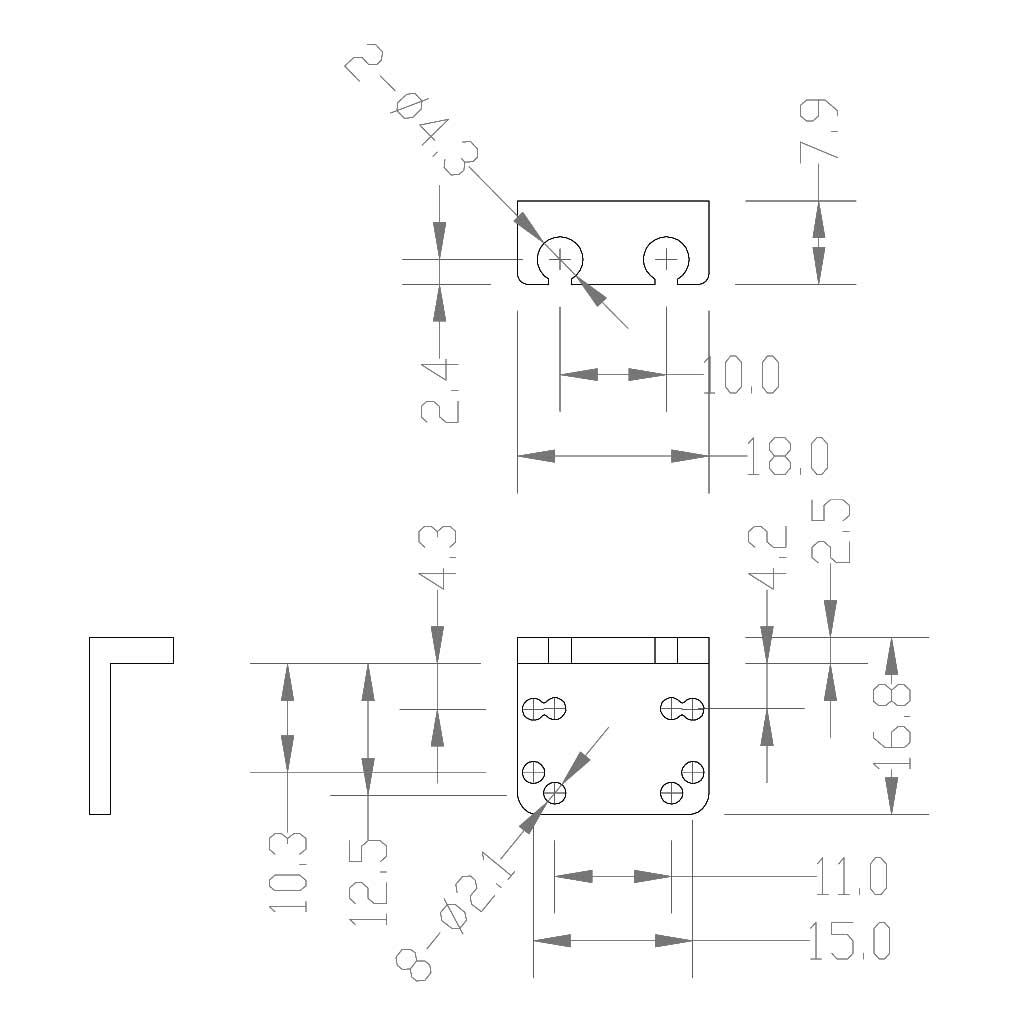

- Multi-mount Beam accessory

Note; Multi-mount Beams are packaged individually. They secure to the servo drive using M2x4 and M2x5 Phillips head screws (depending on which sides are put to use). Using these as the foundation of the mount for your installation greatly increase the versatility of the dual shaft servo drive installation because they can be quickly secured to any of four sides - or - in combination to aid in prototyping, or production use. Their existence is expressly for the purpose of helping you customize this servo installation to suit your mechanical requirement.

Drive Wheels

Once mounted, making use of the output is a matter of adapting the dual shaft to what best suits your needs. Sometimes a conventional arm or horn (of which we offer many in both polymer and aluminum) is all that's needed. However, the selection criteria that sees most using a counter-shaft equipped servo is to balance the output and move an arm or propulsion unit.

At its most basic, we offer a set of Drive Wheels. As long as you have the capability of fabricating to the required accuracy, these are a great start from which to proceed.

- Drive Wheel - accessory

One wheel is broached 25T for for the output-shaft. The mating wheel is bored for the counter-shaft. Both are drilled and tapped on a radial pattern for M3 hardware. Deceptively simple, these team up to make it easier for you to harness the motion control system.

Together with the Multi-mount Beams, a set of Drive Wheels are the foundation of

putting this servo into harness. After all, putting the DS905BLWR to work is the

purpose, right? From here, any well equipped machine shop will be delighted to

begin from here to fabricate whatever is your heart's desire.

- Cross-swing Beam mount

- Multi-beam mount

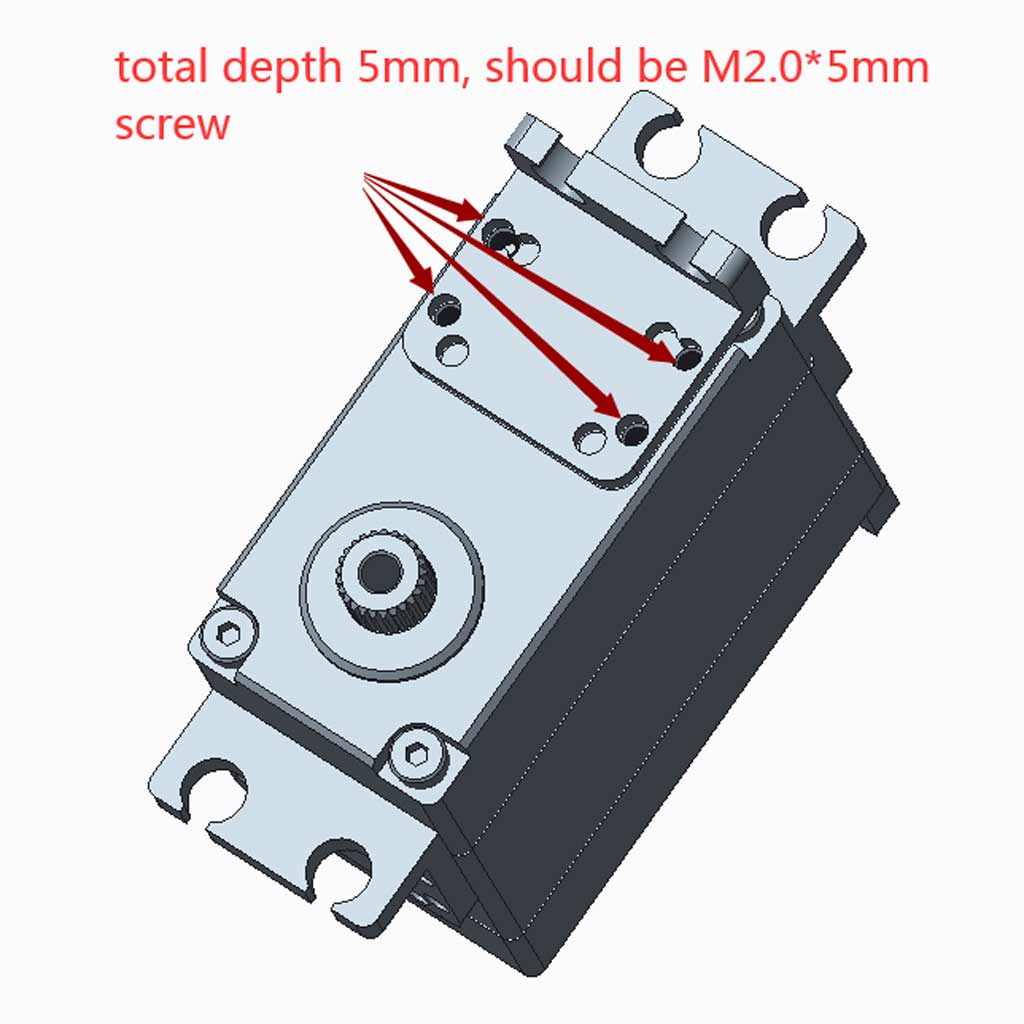

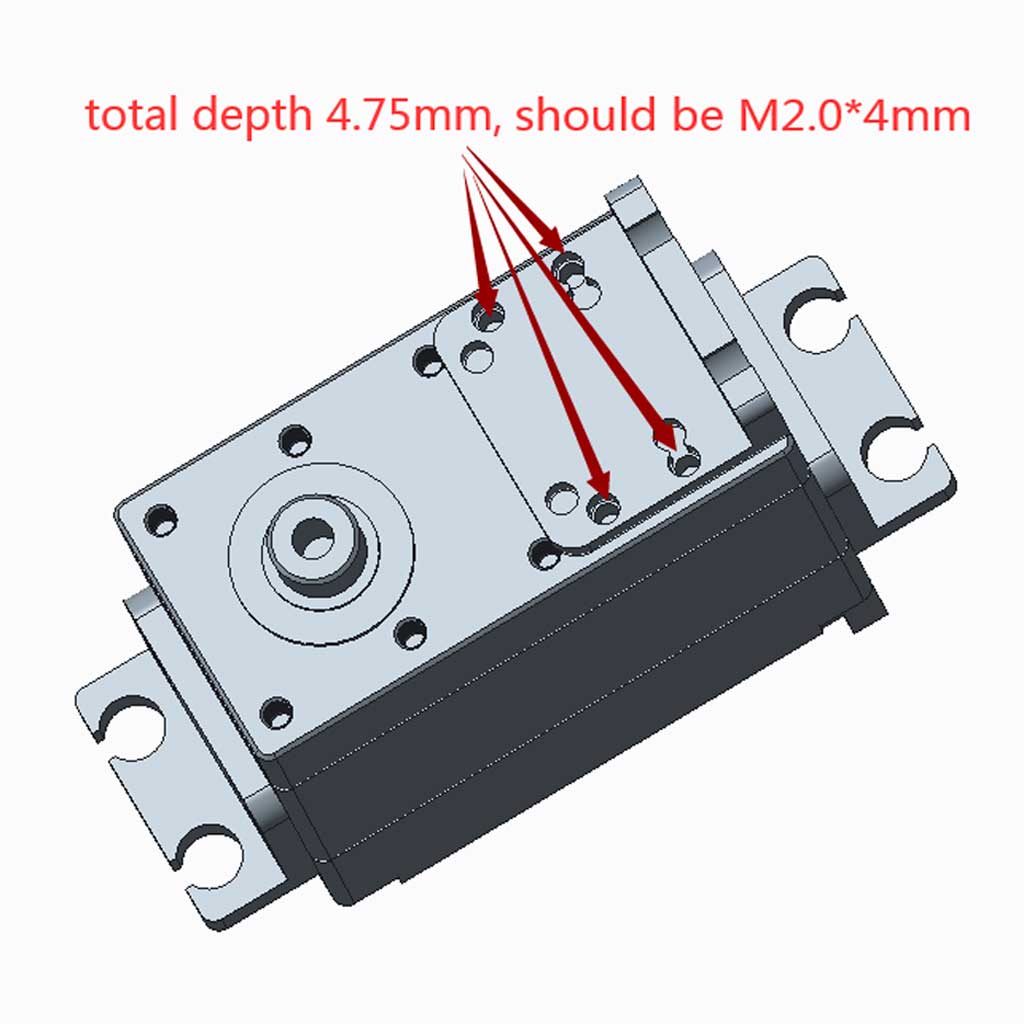

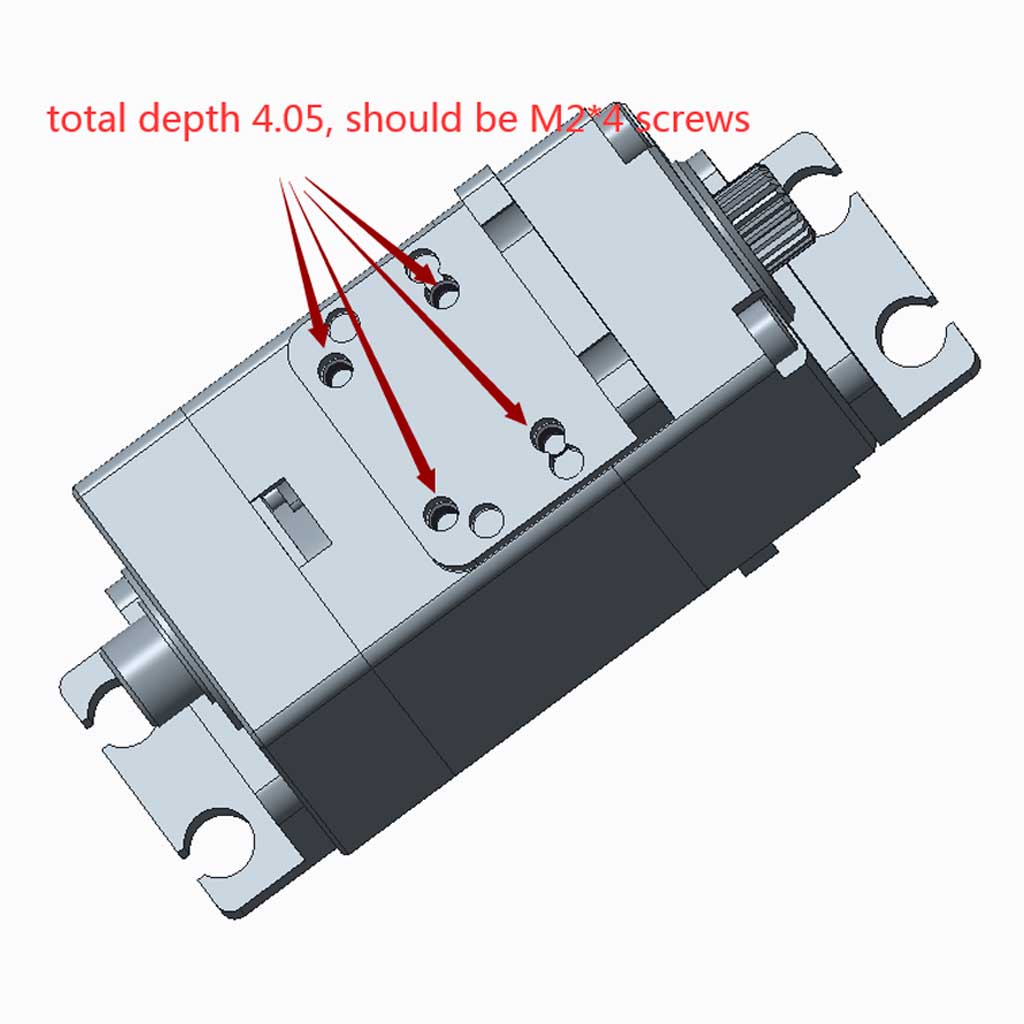

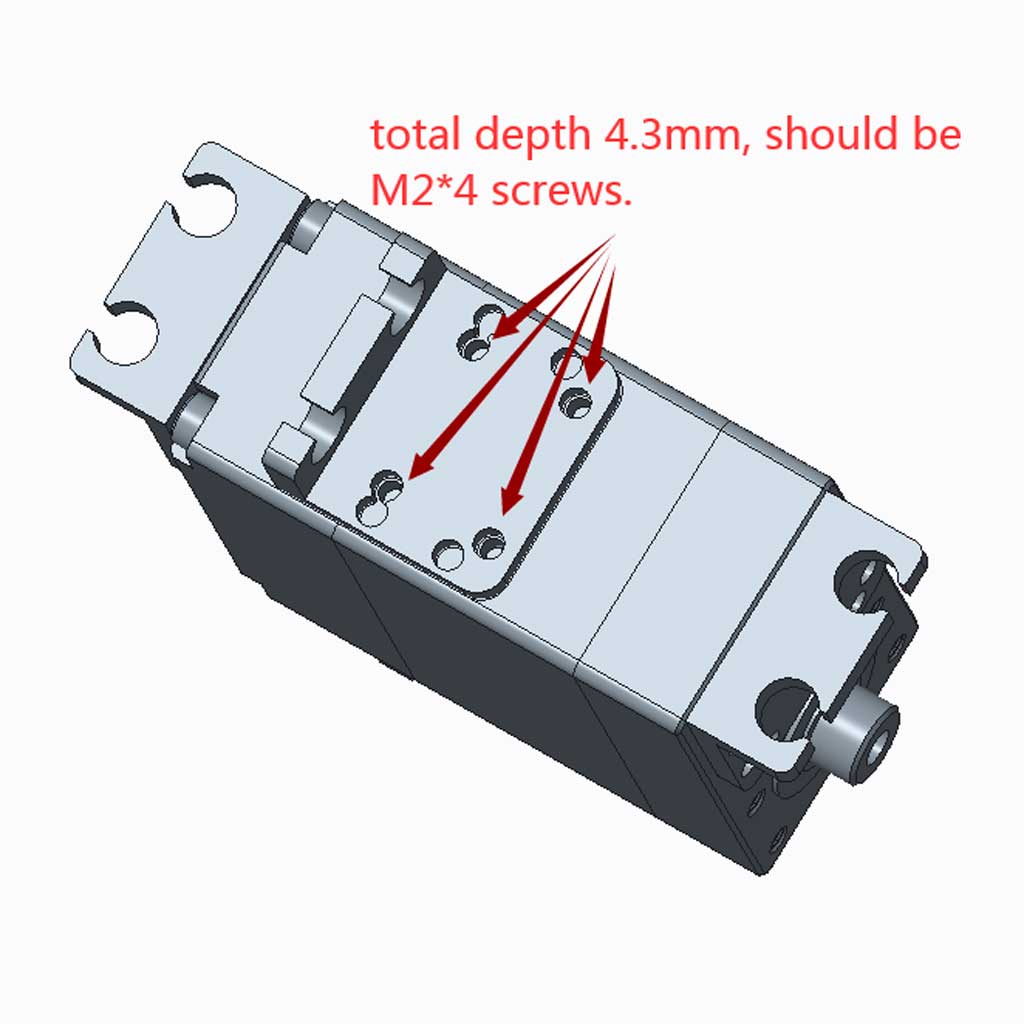

Heads up, the blind holes in the servo case, tapped M2, vary in depth depending on which side is presented. This is because there are components within the servo precluding our boring these deeper. Moreover, because M2.5 or M3 require more lead-threads, M2 is the best compromise for attaching these mounts.

So what's important about this is the 25T drive-side, the support-side, the lead-side, or the smooth-side are all different. So pay close attention - or - when installing these mounts, you'll strip out the threads by bottoming in the bore - you've been warned!

YOU, AND YOU ALONE ARE RESPONSIBLE FOR THE FINAL BOLT LENGTH. IT'S ON YOU TO VERIFY AND TOUCH UP THE LENGTH OF THE MOUNTING BOLTS PERHAPS WITH A FILE TO ENGAGE EVERY POSSIBLE THREAD - HEADS UP!

- 25T drive-side

- Support-side

- Lead-side

- Smooth-side