What's this servo for?

Suitable uses for a DS2180BLDP include large unmanned vehicles for civilian consumer, defense contractors, ordinance disposal, and industry like;

- High performance RC trucks ranging from 10-20KG

- Fixed-wing tactical UAVs grossing 25-250Kg

- Squad-level remote sensing/surveillance

- Rotary-wing agricultural-spraying to 400Kg

- Ordinance disposal manipulators from 20-80Kg lift

The DP in the model number means this servo requires Direct Power. It uses a 2S pack. We have them in capacities ranging from 650mAh to 6000mAh. The most popular pack is the B2S2500 and if you want one, then remember to add it to your order. Or select it from the pull-down menu under Power Options. Anyway, whether you buy a pack from us, or not, just so you know, the 2500 is the most popular size, and it uses an XT30 - keep this in mind.

Also, if you have other ideas for powering it, like maybe using a stand-alone BEC like a Castle Creations CC BEC 2.0 or similar, it's unlikely to have the stones to run the servo at full power. Or if in the alternative, you're thinking of just tying into the propulsion pack, instead (by tapping into two cells via the balance connector), then please be aware ripple (electronic noise) due to the motor/ESC (as it varies throttle position) will backfeed into the circuit (on the servo) and damage a component on the PCB. We're expressly warning against doing this so you know in advance that repair cost won't be covered by warranty. Not trying to be an asshat, but also don't want this to become a problem, so heads up, eh?

Click Specs next.

Specifications

MIL SPEC

MIL-STD-810G-Part 16

- Shock - Test Method 516.6

- Vibration - Test Method 514.6

- Rain - Test Method 514.5

Making the ProModeler DS1735BLDP better is that unlike hobby-grade servos, it's built with MIL-SPEC components and tested to these MIL-STDS (military standards).

These are real world ownership considerations applicable to civilian-use, also.

Product Details

The principal DS1735BLDP use in RC trucks is steering. Big fast powerful rigs abuse steering servos like nothing else on Earth, but durability is the prime consideration.

Demanding applications like an SCX6, 1/5 EXB, or DBXL-E (and a host of others in the heavyweight-class) require the best performance considerations - like centering, power, and speed - but always rugged durability above all. This servo is engineered to deliver in spades! Let's see where the ruggedness is built in.

For example, the all-alloy case looks trick, but lots of imports servos have alloy cases. What separates ProModeler is how it's built.

Case has several jobs . . .

- Mounting tabs

- Cooling fins

- Transmission section

- Hard points for gear shafts

- Steel gears

- Environmental protection (seals)

Electronics Section

- Million-cycle potentiometer

- Potting compound on PCB

- Slip-fit brushless motor

To begin, the foundation is the 10-bolt construction. It's one where Allen head machine thread fasteners thread into the center case. This makes it more rigid in torsion (twisting force that's trying to lever the case sections apart and screw up the gear mesh). Reason this is important is if the gear-mesh changes under load it creates bad wear patterns leading to failure (basically bad juju for any servo).

Speaking of gears, they're all-steel. Why steel? Simple, because it's the best and most durable material available. For example, did you know NASCAR, drag racers, Ferraris, and Corvettes use all-steel gears, also? There's nothing better. Fact.

But equally important is where the steel gear shafts are anchored. In this servo, the gear shafts are anchored withing bronze hard points embedded into aluminum. These reinforce the case and spread impact loads. Servos without these soon end up with round bores for the shafts that get pounded into an egg shape, thus allowing the gear mesh goes to Hell.

Believe me, if that happens then it's new gears 'and' a new case because you can't put new gears into a case with worn bores (you can but they'll get trashed really quickly). So what this really means is those servos are throw aways. It's out view you're better off if we reinforce the case to begin with, agreed?

Installation - Axial SCX6

Installation - Losi 5iveT

This area will contain installation tips for this servo.

Installation - Losi DBXL-E 2.0

TEMPORARILY shows DS1885BLWR being installed but the DS1735BLDP fits similarly

Installation into this Losi DBXL 2.0 is a doodle. Basically you're going to shim it 5mm higher and replace the stock arm with one of ours along with a pack of adjustable links to compensate for the slight difference in output shaft position. That's it, easy peasy!

So the first step is to survey what you have, often a Spektrum SPMS906 steering servo.

- The stocker is a Spektrum servo, not bad per se but no pork belly, that's for sure!

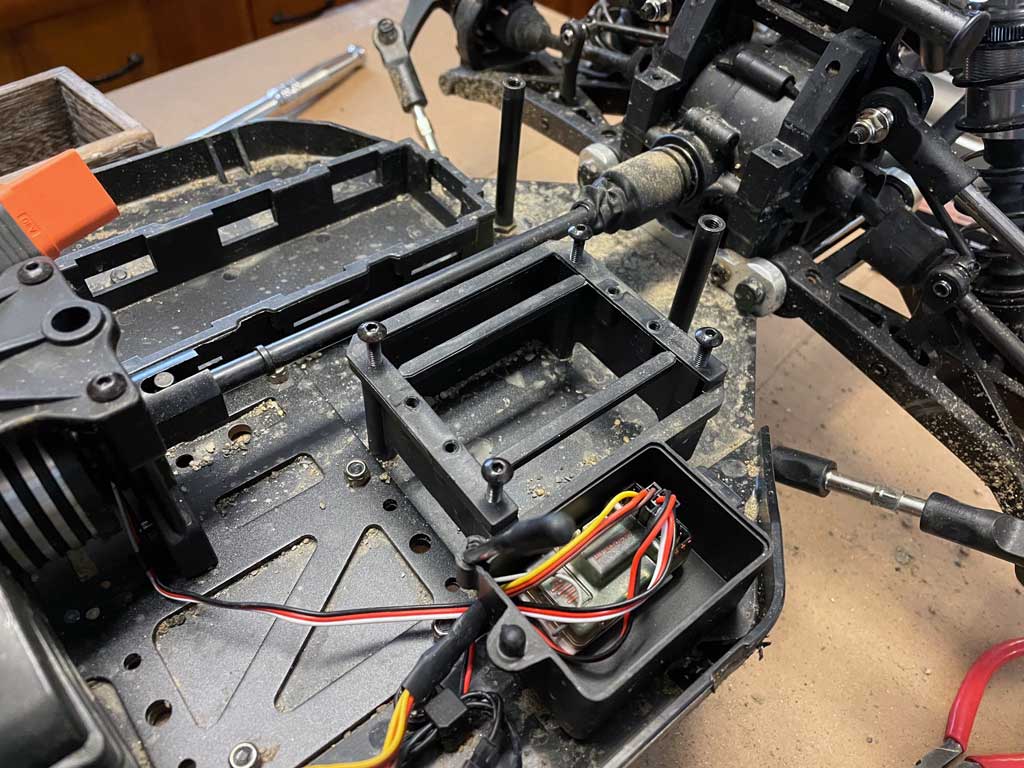

Step two is removing the stock servo, which is so easy we won't tell you how. Please excuse the dirt!

- Look at the size of the installation bay - it's ginormous.

So next you're going to fix the beam mounts to the servo. A small drop of threadlocker is all that's called for, word to the wise.

- One the beam mounts are installed we're almost there.

All that's left is to shim the servo. Some 5mm thick shims will do the trick (hardware store item)

- Looking pretty good sitting there, eh? The Losi DBXL-E 2.0 is very generous in terms of space with which to work.

So we're almost done. All you need is a set of dual-linkages to replaced the fixed length plastic pushrods with ones you can adjust.

- While there are tons of available linkage kits, Losi's LOI351014 work just fine

So the last step is to install the linkage rods onto a servo arm and a PDRS40D-15T will do nicely.

- Subtrim the servo center, and set the end points and you're done!

Installation - Kraton 8s EXB

This area will contain installation tips for DS1735 servo as soon as we receive

What you get

This area will contain what you get for this servo.