As is often the case, these askJOHN articles come about because of a problem someone's having. A fairly common issue regards wanting to use a HV servo - like everything in our lineup - perhaps a DS1155BLHV - with the stock Traxxas X-MAXX radio system (6V). Your hobby dealer offers a nice solution in the form a new radio system. This works because any aftermarket radio system designed in the last decade is optimized for high voltage servos. What this says about Traxxas is not our remit to comment.

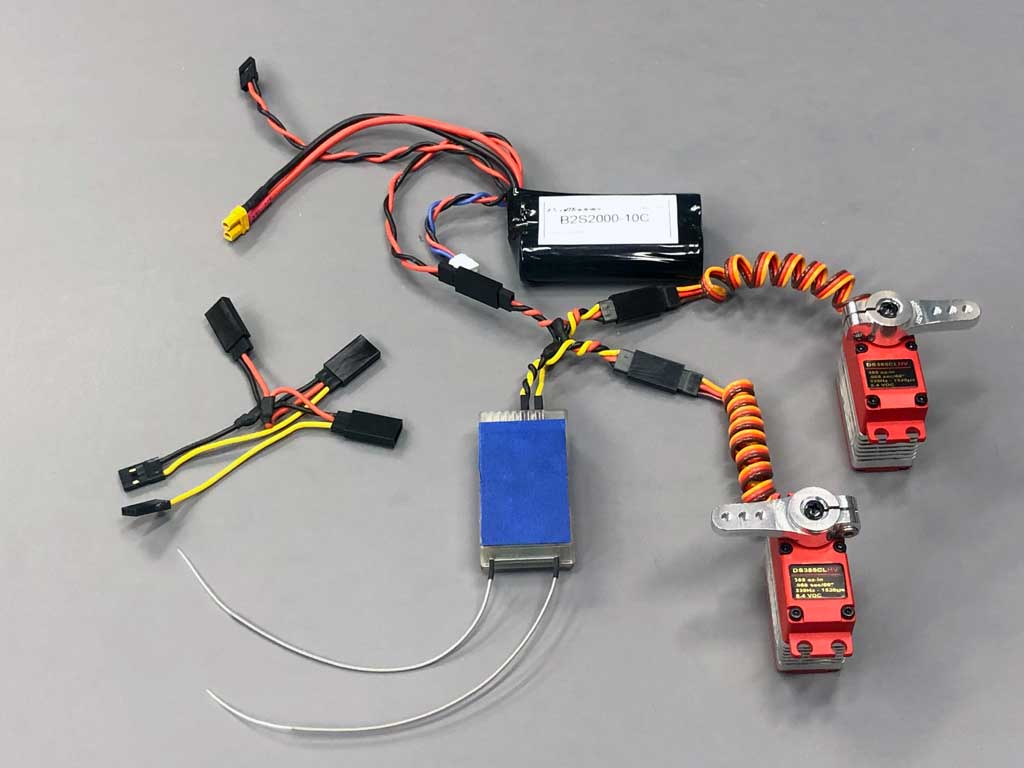

However, this power adapter is all you need to power a HV steering servo

separately from the 6V radio system without burning up the receiver/ESC.

- This adapter gives the servo 10A of HV while the receiver runs on a BEC

Background:

The stock TRAXXAS radio system operates on 6V. The 6V-receiver is

backfed through the throttle lead coming from the ESC (through what's

called a BEC-circuit). BEC stands for battery eliminator circuit and ESC means electronic speed control, or throttle (for the propulsion motor).

Basically, a BEC is like a parasite because it steals juice from the

propulsion batteries (the ones that power the rig's drive wheels) to

supply control-power for the radio, or control-system (this also costs

you some running time, of course). Thus, it's through a BEC that low-end

radio systems (and the steering servo) are powered.

While this

is fine for toys because it's a cheap solution (remember, the whole

package price is what they're concerned with), once you want to install a

high performance steering-servo, the whole house of cards falls down

because SV-systems (standard-voltage, or 6V) as produced

by a cheapo BEC is simply not powerful enough (it also doesn't have the

balls to power a real servo even at 6V because it doesn't produce enough

current).

Recap:

So the problem is, when it's time to upgrade the steering servo,

because the best servos are optimized for 8.4V (what's called HV for high voltage),

then the dealer chuckles and reaches under the counter to pull out a

new HV radio system for another few hundred bucks. This is how the game

is played, e.g. lure you in with something that's great fun and once you

discover the limits, sell you upgrades so you can really enjoy it.

Solution:

Thing is, you don't have to do that because there's another way. Best

part is, it doesn't have to cost much! This little adapter divorces the

control power (for just the steering servo) from the receiver. Now you

can connect an 8.4V source without frying the 6.0V receiver! And note,

unlike cheapo imports, this one's made with 20AWG vs. thinner 22AWG

leads for higher current handling capability - details matter, right?

- Using a 10A HV2SV power adapter is slick solution that saves money!

ProTip; the high voltage source can either be a reliable 2S2000 battery pack, suitable for 6-8 runs between charges - or - an aftermarket BEC.

Servos don't really care, and both of these links will open a separate

tab in your browser . . . but sensitive electronics do better with clean

battery power. Fact. Anyway, we offer you both (BEC and batteries) so

we don't really care which you get, but we recommend the battery.

Yes, this means powering your radio system just like the gas-powered

trucks but because batteries are a significantly less noisy power source

than anything synthetically derived from the propulsion battery, the

system isn't stressed as much. Basically,

a BEC (and we mean any BEC regardless of how expensive) when compared

to a battery (even the cheapest) outputs junk, e.g. very dirty/noisy

electricity (click the link to learn more). Why? Physics.

- 2S2000 LiIon cells (durable steel shells) secured with heavy duty Velcro

Bottom line? Your money, do whatever you want but we don't ever

recommend anything but a battery to those who want the best source of

electric current possible. Anyway, with this adapter, your poor receiver

won't go poof as it suddenly releases the magic smoke from inside,

which keeps it working (just kidding of course, the 'poof' is the 6V

receiver frying from over-voltage, e.g. burning up, if you were to try

using 8.4V).

- Doesn't look like much but it works and saves from buying a pricey radio!

So what if you have a TRAXXAS E-Revo, which uses two steering servos? Well, guess what? We've an adapter to simplify your life with an E-Revo also!

- Just what the doctor ordered for an E-Revo, the HV2SVdual power adapter