UPDATED 3-13-2024

As is usually the case, one of these articles comes about after someone asks my opinion regarding one of our servos. This time regards using a DS630BLHV for steering a Traxxas Sledge. Note; the D630 and the DS505 are sister servos differing only in their motor, so mechanically, when we're talking about one, it stands in for the other, also. Anyway, to get an idea of how they're built inside, then review this article where we repair a couple of very badly damaged units.

And I bring this up because before this update, I actively steered folks away from the DS505/630 and toward our BLS2 servos, instead. Well, crap, it seems this wasn't such smart advice because I've had LOTs of folks reach and say, 'Hey, John, what are you talking about? My ProModeler DS505/DS630 has been working fine for a year!', or words to that effect.

So a bit of further digging revealed the obvious, the best servo for the Traxxas Sledge depends on you, and 'your' needs, and not just what the rig may call for. Like this is so obvious I feel embarrassed but sometimes I can be a duh, so . . . Mea culpa, mea culpa, mea maxima culpa!

Here's what we did. We reached out and touched a couple dozen Sledge owners and quickly learned what should have been obvious, we have three fundamental types of customers. We'll split them up into groups or classes.

Class 1

A fair number are running a pretty stock rig. The Traxxas 2275 servo broke. They experienced a variety of failures like gears broke, case cracked, or just up and died (proximate cause unknown). Many/most got a replacement under warranty and once it went south again, they figured time for something else. A defining characteristic is they bash the rig but relatively lightly. That, and they simply do NOT want to spend a lot of money on it, or time making repairs. They're basically happy enough with the stock 6V radio - they just wanted something 'better' servo-wise. These are basically happy, fundamentally-satisfied, Traxxas customers running our servo at 6V on the stock BEC.

Class 2

This group can be broadly classified as into modifying their rigs, but lightly. More aggressive tires, maybe a nice brushless motor and better ESC, possibly a few aluminum accessories, and definitely a nicer radio. One that's 8V capable and costs maybe $250-300. And they're driving the rig harder. Let's call them a more wild than mild, but not gozo nuts or crazy. They folks are out bashing with their friends, and pretty hard sometimes, but in a way I would maybe define as relaxed and gentlemanly. Fun with their pals, but not at the crazy, 'Hey guys, watch this!,YouTuber-level.'

Class 3

Then there are the guys, what's the word? The ones who may be fairly referred to as hooligans. They maybe aren't crazy, but intense is fair. An $800 radio? Yes? How about a $400 motor/ESC combo? Yup! And if not insane speeds, definitely going a lot faster and hitting skateboarder ramps to catch air! Their rigs are as far from stock as you can get, e.g. M2C chassis, upgraded shock, axles, gears, where Hot Racing and Vitavon are all over their rigs. And they're hard on their stuff. Like they tore up the stock servo the first day. Have tried and broken imported badge-engineered servos and now they're hoping - not for an unbreakable servo because they're savvy enough to realize 'that' doesn't exist - but will happily settle for as close to bulletproof as man can make. They reach out to us for advice, or often just buy a BLS2 without our recommendation because they know what they want without our input.

Summing up where we are

So because a Sledge above all is a pretty big and fast - and capable - rig, right out of the box, we're making some adjustments in our advice, All three classes still need a mechanically strong servo, but some, mostly those in Class 1 are fine with a BLS1 servo, those in Class 3 are the very definition of drivers leading us to create the BLS2 servos. There is a far bit of crossover in Class 2 and Class 1, with some being fine with a BLS1 and others definitely being BLS2 users. And anybody in Class 3 should get a BLS2 but some Class 2 are OK with a BLS1. As always, it depends. On what? On you and how you drive.

Since we've never driven with you or know you, then we're going to stick to the question and answer format to help you define your own needs based on what others do.

Just remember, the defining difference between BLS1 and BLS2 servos is the latter have bigger gears and shafts plus a larger output spline! And they cost more.

So for the more nuanced take, read on . . .

Q1. I've heavily modified my Traxxas Sledge with aluminum upgrades. Thinking of an M2C chassis next. I broke the 2275 and wonder if the DS630BLHV is a good choice since it has steel gears. Also, I've heard ProModeler servos won't work when plugged into the receiver, so I'm confused about this. Also, what's the warranty?

Q2. I am running a modded Traxxas Sledge with Hobbywing 5EZ package. Can I plug the DS505BLHV straight into Futaba receiver and use it? I've seen something about you recommending a separate battery so what's the real story? Also, I originally bought a servo off Amazon and couldn't get warranty help when I tore it up so is there any warranty for ProModeler products? Thank you.

Q3. I'm buying a Sledge but don't have it yet. Everybody says the stock servo won't last but when I look around for a replacement I hear so many things I'm a bit overwhelmed. I'm also building my stash of upgrades. My buddy says Vitavon and Hot Racing and best and I'm looking forward to tricking out my rig. He just got a ProModeler DS845 says this is what I should get, also. And what other items would I need?

Q4. I've been running my Sledge about 6 months and just broke the servo. The case cracked when I crashed jumping off a skateboard ramp a neighbor loaned me. I want something built stronger but I don't really want to spend a lot of money for it. I've been pretty happy with the stock servo so what do you recommend?

Q5. My neighbor got a Sledge so I got one, too. Then a couple pals from work got one and we meet after work at my place because there's a overgrown BMX track at neighborhood park we're running around on. We've been carving the curves and shooting rooster-tails more than 5' behind us and we're thinking of bringing in a few loads of dirt to make some jumps but there's a HOA and the President say no. Our track is fast and two pals just got Savox 2210SG and the specs are a lot better than the it didn't really seem to make much difference until one upgraded to a Hobbywing ESC and motor. Now we've all Hobbywing G2 ESC and motors so I want a servo to beat him like I did before. Someone on Facebook recommend ProModeler but you have so many servos that will fit, I don't know which one is best.

There are actually 6 maybe 7 questions within these five queries;

- Is a DS505 or DS630BLHV a good choice for a Sledge? Maybe but all these folks say modified rigs so probably not. Q4's servo lasted six months, and he's basically happy but wants something more rugged so he's definitely a candidate for a DS505 or DS630. Probably the DS505 since he mentioned price.

- Does it work when connected straight to receiver? Yes, but . . .

- What's the warranty? 1-year

- Which servo do you recommend for a Traxxas Sledge? BLS2 . . . DS635/845/1155. Which is best? It depends on weight and how hard you are on the gear. And do you have how to feed it enough, current-wise.

Is a DS505 or DS630 a good choice? Since the only difference is the motor (otherwise, they're the same servo), I'll answer for both with . . . nope, not really a good choice. Not for such a fast and heavy rig as the 1/8th scale Traxxas Sledge loaded with alloy upgrades. These make it heavier and the heavier they are the harder they crash so it also means this probably isn't the right servo for you (sorry if it's not what you want to hear, but you did ask).

Why not? Honestly? I wouldn't recommend any of our BLS1 brushless servos for the job (DS505, DS630, and DS930) when the rig is modified with a lot of alloy and bigger tires and a brushless motor. Maybe the DS930, but even then not really because all 3 share the conventional 25T output shaft (like the stock servo). And note; we're using the best steel there is yet it can twist upon impact when a rig is either fast or heavy. So we feel the rig just needs a more heavily built servo.

Eyeball this photo of a DS630 shaft damaged by a heavy rig. It's been twisted because of the external forces of hitting a stump or a curb (most likely). And we've even seen them snapped in two! And note; anything that happens to this servo, with the best steel money can buy, definitely will also happen to the 25T output spline of any other servo on the planet.

- This is a steel output shaft of a DS630 twisted like a pretzel by an impact

Here's a photo of servos with a 25T spline shaft and a 15T. Take note the ginormous difference in the size of the spline! It's massive. In fact, it's what we use for our line of quarter scale servos, the ones outputting from 1500-2700oz-in. Anyway, once we updated them to the gnarly 15T spline, twisted shafts became a thing of the past. So the question you have to ask yourself is, how hard are you on the rig. If the answer is hard, then the smart money is on a BLS2 series servo.

- The larger shaft of the DS635 version 2 in the foreground

By the way, the spline isn't the only thing bigger about a BLS2 versus BLS1 servo, there are also larger gears inside. So let's frame this a bit better with another photo. This next one shows the relative size of DS505/630 output shaft on the left (remember they share the same gear train, just a different motor), then our DS930 output gear in the middle (also 25T), plus the 635 V1 output gear. While the 930 gears are larger than the 505/630, note how the 635 gears are a shade larger.

- ProTip: the output gear is the biggest gear in the servo because it deals with the brunt of the forces involved upon impact

- DS505/630 on left, DS930 middle, DS635 right

Background

So the output gear of the DS635 is thickest, next is the DS930 gear, then the DS505/630 which incidentally, has about the same size output gear as a Savox 2290SG. But don't mistake the DS505/630 gears for weak, just not our strongest. And don't misunderstand what we're saying; 505 and 630 are great servos, just not ideal for *hard* bashing.

Summarizing, it's my opinion, the right servo for the Sledge is going to see you stepping into a BLS2 servo instead of one of our BLS1. However, no matter what 'I' think, you're the customer - so you're always right - and if you want to use a DS505 or DS630 because you don't think you're going to stress it very hard, then KYO because you're a big boy and it's your money. But since I'm being asked for *my* opinion, then you're getting my unfiltered thoughts, capisci?

- Yes, I'm telling you straight up; don't buy a DS505 or DS630 for a Sledge, get a BLS2 servo like a DS635/845/1155, instead. Which one? It depends how heavy the rig is.

ProTip - while we offer three BLS1 servos and three BLS2 servos (DS505/630/930 versus DS635/845/1155), and while all six are about the same physical size (meaning a standard class 20x40mm footprint servo with conventional mounting beams), and while all 6 have all-steel gears, the BLS1 servos are far more suited for crawling and light duty bashing versus the BLS2, which are optimal for heavy duty bashing and launching your rig off a ramp.

So it's down to larger gears and shafts that recommend the BLS2 over a BLS1, and because of the 15T output shaft more ability to absorb impact and shake it off. So a BLS2 compared to our own BLS1, and *any* 25T servo available the BLS2 is substantially more beefy.

Note; mention of the 25T output shaft means is the same size as Futaba, Savox, et al.

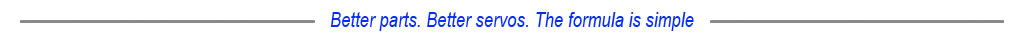

So for hard bashing, you're going to be way ahead of the game by opting for the significantly more heavy duty drive train of our BLS2 servos. Eyeball the next picture to see how they're built inside (photos of a type competing products never show you).

- Note the massive shafts and heavy reinforcements

What do you see? Not just big ass gears and larger diameter steel shafts, but look how the alloy case is heavily reinforced with bronze inserts. These are called hardpoints.

So basically, with ProModeler you're getting better parts from which to begin your adventure with your Sledge than if you bought an ordinary import servo. After all, better parts make for better servos, agreed? And we're trying to earn your business the old fashioned way . . . by giving you more bang for your buck!

DS635 or DS845 or DS1155?

OK, so we recommend a BLS2 servo instead of any of our BLS1, check. But which of the three is best? Short and sweet . . . it's our experience our DS635BLHV is well suited for the largely stock Sledge. But we don't know you. So if the servo is destined for a heavily modded rig, meaning heavier because of the addition of accessory alloy parts and bigger rubber, then we advise you opt for either our DS845BLHV, or DS1155BLHV (for the added grunt required when turning big heavy tires at high speeds).

The more nuanced reasons why . . . it's because more power is required as weight and speeds go up. Means it takes more torque from the servo to meet your expectations. And this is true even if you buy an import like a Savox 2290SG, an otherwise pretty decent servo.

Look, in offering up 22 volts of oomph, Traxxas put in your hands something which will hurtle into the 70s speed-wise! To put this into context, 70mph is about 100fps (feet per second). Since the average house is about 100 feet long, it means this thing is hustling along pretty quick at top speed . . . it's über fast (a technical term for lickity-split)

And your Sledge carries a lot of beef. Moreover, a modified version (with bits and bobs made of alloy and steel) plus larger tires? Well it weighs even more!

Why heavy and fast - together - matters!

Why? Simple, let's turn to Newton's law of Motion (there are three). The 2nd and 3rd are germane to the Sledge discussion. The 2nd states that the force on an object is equal to its mass times its acceleration. Written it looks like this; f=ma*a . . . if the mass is the same (same rig no matter how fast), as you're going faster and faster (definition of acceleration), then the faster you go the harder you hit the fence post, or plant it after a 100' jump. Means ultimately, something's gotta give! So that's 2nd law.

Meanwhile, the 3rd law states there's an equal and opposite reaction for every action. So if your rig just kisses a curb at 70mph then it's the same as if it were standing still and the curb came out of nowhere and hit your Sledge - at 70mph - it's the exact same exact thing, either way.

Put 2nd and 3rd together and it means the force being generated - maybe just cutting the wheels at a bit of speed - can be enough to overwhelm the gear train and spline of a conventional servo. Conventional being our BLS1 servos (as well as competing designs like Savox 2290SG, MKS HBL599, or Futaba CB700). Why? Just because a lot of mass at speed is harder to steer because it imposes higher forces!

This next photo shows the comparison of the Savox 2290SG gear train to that of the DS635 and take note of the relative size of the final drive, the output gear, the largest within the servo. This is an example of how bigger is better. Our series II servos are beefier inside and just more durable.

- 2290SG gears juxtaposed with DS635BLHV gears

Continuing with comparison to the Savox 2290SG (a good servo, we're not saying otherwise), but this time juxtaposed with the DS630 (instead of the DS635 we recommend), and which to remind you, differs in the motor only from the DS505, note the construction . . . one is reinforced, the other puts the steel gear shaft directly in the aluminum.

Steel, bronze, and aluminum - of course - are metals, but the bronze is second only to steel with regard to hardness within our servos (and both are FAR stronger and harder than aluminum). So putting a harder metal (steel or bronze) in place (an insert) to shield the soft aluminum is called metal reinforcing. So we use bronze (and sometimes, steel, or even bearings) when reinforcing our aluminum alloy servo cases where shafts fit in the highest impact location. In fact, we're unique in the industry in bronze reinforcing even our entry level $29.99 servos!

Which is best? Honestly, any of them are way better than the big fat nothing you find inside more cheaply manufactured products (to include the no-names on Amazon) plus a host of servos available by online hobby shops (ones who instead of handling quality brand name products seek a low cost manufacturer in Asia to produce their private label offerings). And note, since we buy competing servos and no-names to inspect for what we may learn, we weren't surprised to discover the hobby shop brands are actually made pretty much exactly like the el cheapo no-name products (and in one instance we know with certainty, by the very same Asian manufacturer).

Anyway, to the question of, is a servo better if it's made with reinforcements, or would you rather have a servo where the steel shafts are fitted directly into soft aluminum? We think the answer is a no-brainer but it's really up to you to decide, not us. Point being, when shopping, just because it's shiny and pretty on the outside doesn't mean jack!

Why the larger spline shaft and bearing?

Because all else being equal, when it comes to trucks, bigger is better . . . and yes, we have a Sledge horn available to suit. Part number PDRS16F-15T. Click the link and it'll open a separate browser tab so you don't loose your place.

- PDRS16F-15T Sledge servo arm uses the ball from Traxxas 2742

Recapping:

So we went bigger with the internal components expressly with the series II in order to handle the forces being imposed by faster and bigger rigs. Recall, Traxxas set about standing the 1/8th scale off-road world on its head with the Sledge. How? By redefining the entirety of the concept through their engineer's bag of tricks.

Tricks? Yes, because the Sledge is a monstrous rig operated at seriously fast speeds on high voltage. Honestly, just making it and bringing it to market (from 'this' product designer's perspective), has been quite an impressive trick in the first place! So trick is the right word in many regards. If nothing else, it's quite a trick rig all in and of itself, too.

Why doesn't Traxxas equip the Sledge with a better servo?

I alluded to it above. Successfully bringing it to market involves a host of compromises. Some will buy it for a 9 y/o who will dink around in the back yard until they break it before returning to their Nintendo Switch, the Sledge forgotten. So if Traxxas used the best of everything it would cost $2000 and nobody but aficionados would buy it - and certainly not the many Moms and Dads shopping for their little kid using a credit card!

So the major difference between you and Traxxas when selecting the steering servo is they have to factor cost above pretty much everything in order to broaden the market to include everybody. Nice thing is this means you can belly up to the counter and plunk down the MasterCard to bring together your vision of the perfect rig, while they have to contend with bringing the whole thing to market . . . at a price for which folks will step up to the plate and whip out the MasterCard!

Enter our Series II servos, which is what we unequivocally recommend for the Traxxas Sledge. But let's laser in on the answer to the actual question (unasked), what's enough torque and why?

- Stock rig, light upgrades - DS635BLHV

- Modded rig, quite a few upgrades and bigger tires - DS845BLHV

- Heavily modded rig, best of the best, fast and heavy as they come - DS1155BLHV

Let's close with regards to plugging it in to your receiver and will it work? Yes it'll work; here's proof!

- But you're asking the wrong question.

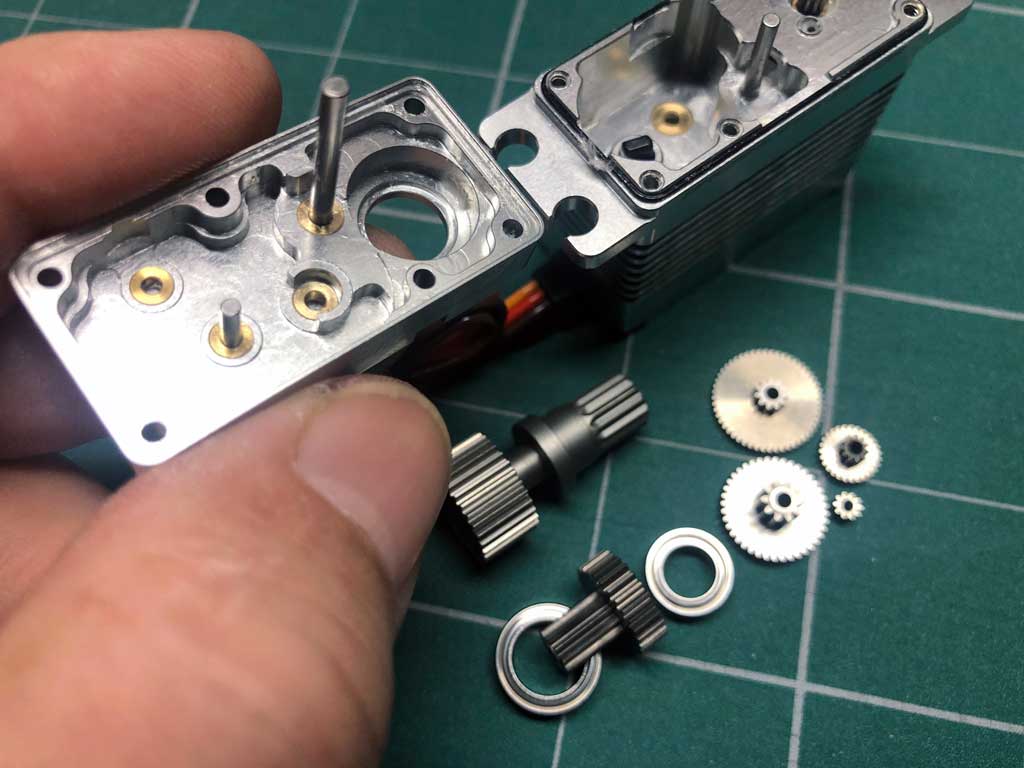

Right question is, will it make rated power when connected to a receiver and powered by the typical hobby grade ESC with a BEC circuit? Nope, I don't think so, but you're free to do as you please because as we said earlier, you're the customer and thus, you're always right.

So if it were me, then instead of relying on a free BEC that came with the ESC,or even an aftermarket one because analog juice beats digital no matter what, then I'd run a dedicated pack like a B2S850 - or - pony up for a good quality stand alone BEC (if you insist on synthetic juice).

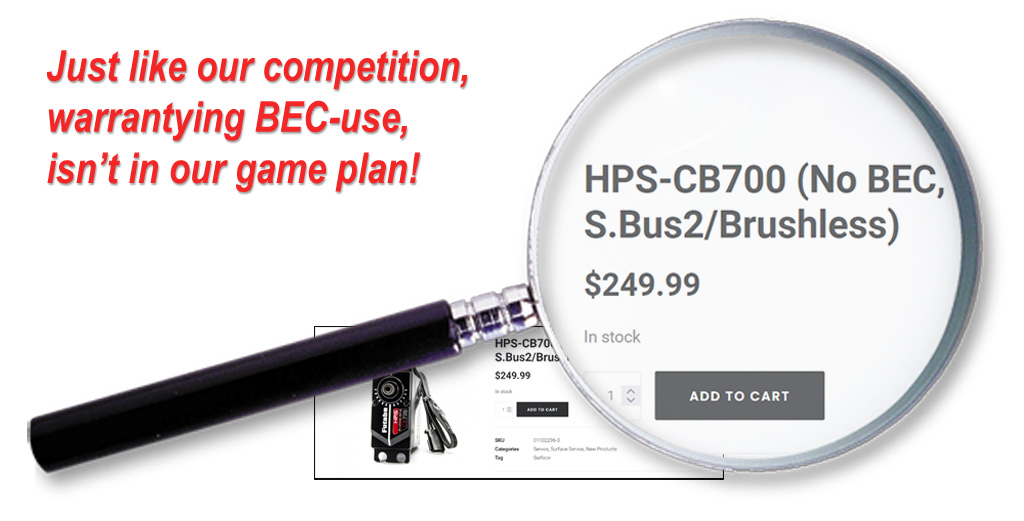

ProTip: while I recommend an 850mAh pack, our packs sizes range from 650-6000mAh, and the 850 is probably about right in my estimation (good for maybe 3 runs between charges), but if you can fit the 1500, then it'll run for about twice as long on a charge (call it every 6th time you charge the propulsion pack). Are we the only ones steering you away from using BECs with performance models? Nope, so does Futaba.

ProTip: our packs (and suggested BEC) come with 2 power leads to the receiver instead of 1. This is because otherwise, you can't comfortably get more than 5A into the receiver.

Eyeball the servo specs. Specifically, look at current draw while stalled (meaning when it's making rated power) and then you'll understand why single-lead 'solutions' are really anything but. One lead is a 5A connection to the receiver so a typical BEC backfeeding the the ESC into the receiver through the throttle channel lead limits you to 5A and begins overheating at the 3.5A the connector is rated for. So using two leads, one to the receiver at BAT and the orher connected to the receiver through an unused channel, maybe channel 4, gives 7A before beginning to overheat, a practical 10A in the real world.

A real world problem is the specs for a BEC don't mean what you think. I'm saying you can't take what marketing says as gospel because they lie. Especially companies selling inexpensive consumer grade goods imported from Asia (or even assembled in USA of imported components).

So like you read servo specs (and a Savox 2290SG, incidentally, makes rated torque at 8.3A), then you also have to read the specs of BECs, also. And if read the specs of products by the best companies, you learn 20A BECs aren't really 20A. More like 7-8 at the voltages we're concerned with. Yup, output current totally depends on voltage input. Also depends on temperature because they rate them at 77°F with a 10fps cooling breeze. Cooling breeze, under the plastic shell of a rig? Hah! Anyway, they rate them for lab conditions. You're not getting what you think and no matter what, they put out digital juice versus analog.

- BEC versus battery is like the difference between Tang and real orange juice!

That said . . . and in fairness . . . while we believe you should use a separate battery to power it, you're the customer and may instead decide to wait and see. Wait for what? Until after you run it a while.

So how do you decide? Basically, if you want more power from the servo (you'll know), then you can order the battery and harness we offer for Traxxas owners (they're a 6V system so the harness splits power so only the servo gets 8V and thus, protects the radio from going poof).

Major point being, some folks are happy enough with the power they get from the servo using the built-in BEC, so if you're one of them, then you don't need a dedicated battery! By the way, I'd share the same advice with you regarding any servo making 500+ oz-in as this is a matter of physics, not opinion so if you decide a Savox 2290SG suits you better, I advise you treat it similarly.

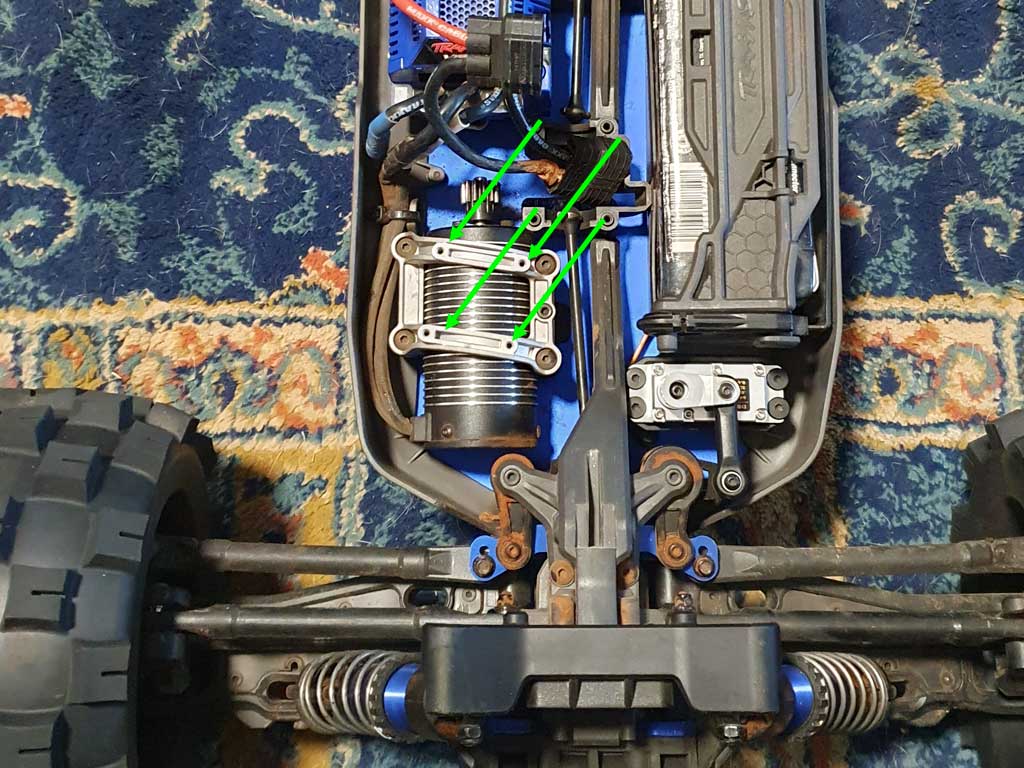

Finally, the Sledge has a pair of motor clamp mounts which have a set of threaded holes in each. This makes for a great place to mount a bit of flat stock material for battery mounting. Use 1/8" plywood from the hobby shop. They sell 6"x12" sheets for a few bucks. Anyway, after you cut it out and drill the holes (obtain by transfer, e.g. rubbing a pencil on a piece of paper), then color it in with a black Sharpie and seal with thin CA glue. That, or a bit of 2mm carbon fiber sheet. Whatever!

- Gorgeous layout of the Sledge is simple yet sophisticated

Speaking of mounting the battery pack, I like using 3M brand Dual Lock Velcro TB4575, which I buy off Amazon. This will readily hold it in place.

Also, if you're curious, these articles touch on why we believe a dedicated pack's better. And like I've said, we'd say the same if you're running a Savox 2290SG, MKS HBL55, or Futaba CB700, or anything else making +500oz-in, then please believe me, a standalone battery is a better power supply for your control electronics than any BEC on the planet.

Warranty?

1-year parts and labor against manufacturing defects and workmanship.

Does this mean you can't break it? Hell no! Why not? Because we're not stupid, modelers can break anything! This includes even our BLS2 with the gnarly gears and massive 15T output shaft.

Anyway, good luck in whatever you decide but please trust my guiding you to a BLS2 steering servo versus one of our BLS1 or any competing servo using a 25T spline because as the designer, I know what our servos can take (and that Sledge is no joke, and definitely not a toy).

Summary

For a stock Sledge I'd use a DS635 and the factory BEC system (means just plug it in where the old servo was and it works). But if you'[re pretty happy with the stock servo until it broke and you just want a better build replacement, then DS505 or DS630 fill the bill nicely. For a heavily modified rig (lots of heavy aluminum aftermarket parts, brushless motor and ESC, larger tires, etc.) then I'd use a DS635/845/1155, and the DS1155 almost certainly with a battery. And I don't advise the BLS1 servos because the more burly BLS2 servos exist for good reason.

And review my thoughts for why opting on a $60 Amazon special isn't such a great deal. Ditto the hobby shop labeled imports because they're the same kind of thing (but with some hobby shop's whiz bang label engineering). Those compared to ProModeler, Futaba, MKS, Savox, et al. Trust me, I make these things and I know more than you - it's the same advice I'd give a nephew.

Of course, you're a big boy, so it's your decision. Anyway, whichever servo you decide is best for you, if it's ProModeler, you're going to like it. Ours are better built and more durable than the imports. There's a 1 year warranty, visit the page for the details.

Last thing; if you just plug it into the receiver and go drive the rig, a DS505 or DS630 will work. And yes you'll be happy - but - I predict one day you'll wish the steering were more crisp at higher speed. You'll want the rig to cut harder/better/sharper and that's when power decisions your make before installing the servo will affect the solution.

Then it's time to either upgrade to a dedicated battery like a B2S850 or an external BEC like a Castle CC BC 2.0 (we have them, too). Or If you're using a dedicated battery or external BEC, then the solution will actually be a stronger servo.

But if the servo is running on the stock BEC, then fixing problem of it not being crisp won't necessarily mean you need a new/stronger servo. Instead, it more likely means you'll need to upgrade how you power the servo (true for any 500+ oz-in servo regardless of brand). I say this because physics affect all servos equally. Nobody makes a magic 500-1000oz-in servo that uses half the amperage of someone else's, OK?

Fundamental reason will be the Traxxas servo-power supply (BEC circuit of an ESC is called a BEC for battery eliminator circuit). Anyway, it isn't really up to handling a high performance servo (which you'd expect since they're intent on building it as cheaply as possible so it sells better).

So the upgrade involves two power alternatives, an aftermarket BEC or a dedicated battery. Or you can spend a lot of money on a new motor and ESC which has a better BEC (and maybe it's good enough, maybe). Anyway, we have both, just click these links to learn about them before ordering your servo. Note; reason we don't recommend upgrading the stock Traxxas motor and ESC is they're actually pretty decent. So I wouldn't do that until they wear out, but it's your money.

Speaking of which, if you ask around on FaceBook, I predict 9 out of 10 say they use a BEC to power their system. But I also bet they've upgraded motors and maybe use an aftermarket ESC like Hobbywing, or similar. Lot of money, and remember, some of those aren't up to the job, either because hairy ass servos consume lots of power (amperage, not voltage).

Me? I'm an old engineer and thus, I know of no BEC that compares favorably to a battery. They're just not good enough. So for my models, I'll take the quality of a battery over a BEC any day of the week. And I advise, until you know more about this than me, you should also run a receiver battery, which incidentally is exactly what all the expensive gasser-powered rigs use.