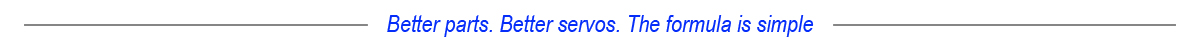

The DS105CLHV is one of four ProModeler takes on the sub-micro class,

which includes three others, the sister servo DS75CLHV, plus the

DS125CLHV (alloy case) and DS125CLHV Brass Monkey. Built for pure torque, this one

outputs 105oz-in while transiting in a blazing 0.979sec/60° thus ensuring

it handily outperforms class standbys like the Hitec HS-65MG (31oz-in

and 0.11sec/60°) or HS-5070 (52oz-in and 0.12sec/60°).

Our

remit was simple . . . produce the best sub-micro in the world. And we

believe we've succeeded with the DS105CLHV because it offers a great

balance between speed/torque and price. We offer it not for those

seeking ever cheaper servos but for the uncompromising modeler. seeking better.

For example, those

whose tastes run toward aggressive 3D maneuvers and those dissatisfied

with ordinary commercial products, e.g. as used within otherwise nice

foam models equipped with garbage $3 servos. Or as a as modeling friend of mine once pithily observed, 'Spending

nearly as much for servos as for the whole damned model seems

positively stupid until you consider it won't fly worth a shit if you

don't!' . . . and he makes a valid point, but I digress.

The

reasons for this servo's popularity principally has to do with its

build quality and astonishing torque as it manages to

make 3X the torque of ordinary hobby-grade products. This makes

it ideal for the dig and shift servos in model trucks like a Traxxas TRX4 as well as 42-48" models from the likes of Extreme Flight and AJ's

Models (plus many others). But take note, those who fly those models hard

typically use a DS100 for the elevator instead of a submicro - heads up, eh?

And

no, it's nothing to do with the DS105 having crappy gears and more to do with

the loads being imposed on by some regimens of flight being just too

much, e.g. some pilots fly the little 3D models so hard they can explore

the actual limits of the product and break it in the air. Fair warning,

OK?

Overall

this is quite the servo, especially for modelers who've been around a

while and realize not long ago standard size servos like the Futaba

S-148 (42oz-in and 0.22sec/60°) were doing 90% of the heavy lifting in

the radio control world. Yet now - in a sub-micro package - you are

being offered a servo that's about 2.5X as strong, nearly +2X faster, but

that only weighs about 1/3 as much! It's really quite the tour de force in miniaturization.

Don't believe us? Survey similar size competitors. What will you

find? Nothing as advanced as what this servo represents. Bottom line?

You get more for your money from ProModeler. Add to it the recognition

the DS105CLHV is flat out built to a much higher standard with better

component parts.

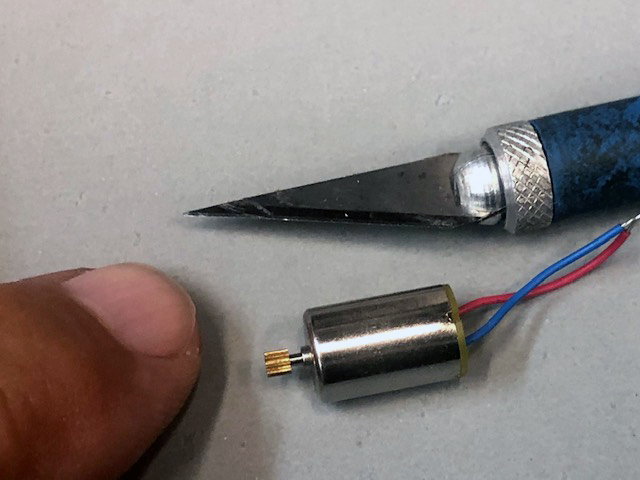

The build standards

For example, there's an aluminum

center case (where they use plastic). We also opted for steel gears

(where competitors use aluminum and brass). Then for increased

durability, we reinforce the polymer case with SAE65 bronze hard points

(while competitors are content with letting the metal gear shafts fit

directly into plastic bores that quickly wallow out under load). What

the bronze inserts bring to the game is enhanced gear mesh, which stays

constant over time. But there's more because there are also 13 o-rings,

which seal it from the environment. Plus a conformal coating on the PCB,

which adds protection against vibrations. In the end you get tank-like

durability built on a sub micro scale!

And the harder you look the more there is to see. For example, take

note of how that center case isn't merely made of aluminum, perhaps a

cheap extrusion, but has actually been 100% CNC-machined. Where the

other guys use pass through bolt holes, this one has been tapped for 10

machine-screws to keep them as short and stiff as possible. Plus there's

an added advantage of hogging the case from a solid billet of 6061-T6

aircraft aluminum - it's those cooling fins.

The cooling fins are the key to the high performance because without

them the motor wouldn't survive when you're really pushing things hard.

After all, heat is the enemy of all things electronic, right? So keeping

the motor cool is a fundamental aspect of achieving high performance.

But the other guys skip this! Perhaps because it's hard to maintain the

tolerances. Or maybe it's because this is expensive to do (it doesn't

matter because those of you who want the very best available immediately

recognize these for what they are, excuses).

Then to help keep the weight down, we use polymer components for

some of the case. However, just as with our larger servos, we reinforce

plastic bores where the highest stresses are created by the steel gear

shafts. How? Through the use of Swiss-machined SAE65 bronze inserts.

This added reinforcement is another reason why you get more for your

money with ProModeler. And it's another part of why we earn a solid

reputation for ruggedness and dependability. Note; we work to earn it

with every servo, but with the DS75CLHV you get a level of precision and

toughness just not found in other brands of servos designed to such a

miniature scale.

Outputting +6 pounds of force there's basically nothing else like

it in the whole world (unless you look at the sister servo, the DS75

and either DS125) so if you love small models 'and' have become

disenchanted by the el cheapo type sub-micro servo offerings

(like what's found in otherwise quite nice ARF foamies), then this is

the best upgrade you can make! Moreover, if your tastes run to extreme

performance wood/carbon fiber air frames, then getting the best air

frames only to equip it with inferior servos really makes no sense. If

you want sub-micro servos built to the highest standards, then the

DS105CLHV is the right servo for you.

Note the tabs above.

- Specs - useful if you're curious about the raw numbers, dimensions, etc.

- Comparison - a guide regarding how it compares to other products.

- TL;DR - gets down into the weeds with the nitty gritty - it's for the detail-oriented.

- Reviews - short and sweet with real names and places - no BS.

SUMMARY:

Part of what makes the ProModeler DS105CLHV submicro better than competitors is that unlike hobby-grade

servos, it's built to meet military standards (and meets these requirements).

MIL-STD-810G-Part 16

- Shock - Test Method 516.6

- Vibration - Test Method 514.6

- Rain - Test Method 514.5

Note1

Note1

These

are tiny servos with even tinier gears and operating them manually via

the servo horn may damage them. This damage is not covered by warranty.

Please do not treat these like a standard size servos. If you fit a

servo arm and zing is back and forth to feel the compression (just

kidding) and damage it, it's on you. You've been warned.

Note 2

Operating

voltage is 4.8-8.4V, but optimal performance is obtained with a 2S LiPo

instead of a BEC. This is because LiPos deliver the required current

without voltage spikes, noise, or otherwise adversely affecting the

delicate avionics (15C or better is recommended). After all, synthetic

orange colored Tang may have gone to the moon, but it doesn't compare to

freshly squeezed orange juice. Same thing when it comes to feeding your

avionics! Learn more by reviewing these articles;

.

. . major point being, individually these things can draw a bit over an

amp so if you have a model jet with 9-10 of them, or a 3D model with four,

which is not hard at all, then exceeding the 3.5A rating of the

connector going between speed control and receiver (the throttle lead is

how the receiver is back-fed power from the ESC through the

BEC-circuit) then it's pretty easy to exceed what is safe. Heads up, OK?

Note 3

We're often asked why we say not to

use this for the throttle servo of model

airplanes/boats/helicopters/trucks since a carburetor only needs maybe

10oz-in of torque. The reason has to do with the tiny component size and

withstanding vibration. Even when we protect the PCB with potting

compound, what we can't protect is the potentiometer because it directly

links mechanically to the output gear. So even when protected with

rubber isolation (which we offer as an option but don't supply as

standard equipment since these things mostly go into small electric

models with relatively low vibration levels), an internal combustion engine (gasoline or nitro, no matter) is feeding vibration into the pot via the throttle pushrod. This *will* destroy the servo - and really really quickly. Point being, we

have too much experience with this and thus, while we love you as a

customer, we don't love you enough to be warrantying what we know will

break. Thus, we'd rather warn you off the product thereby risking the

sale from the get go, capisci? What would we suggest instead? Maybe a

DS100 is the better alternative but in truth, we'd really rather guide

you to a standard size DS90DLHV equipped with a PDRS105 servo horn.

Review this article to learn more.

. . . and note,

while this is aimed at modelers with gasoline engines, the same holds

true for cars and trucks, boats, and helicopters with high RPM nitro engines which typically also use a very short 1/16" steel pushrod to make the linkage. Trust us we know what we're talking about . . . please!

Ownership Considerations:

Competition pilots - especially those who fly precise maneuvers - prefer ProModeler servos

because we use MIL-SPEC components (plus a genuine Japanese Nobel-brand

potentiometer). Others? They're satisfied with a cheap clone, a magnetic/

inductive pickup, or some other cost saving variation of a potentiometer. Also, and especially important for IMAC and pattern competitors who fly a lot and thus, go through and R&R their servos each winter, we offer spares. And not just the case and gears like everybody else, but the spares that count - to include the potentiometer and the servo motor. Plus little things like o-rings, bolts, and even the label. So instead of being forced to return your servos for service, if you can DIY, you can save money!

Why the emphasis on competition pilots? It's because these folks fly 30 times a week (and do it week-in, and week-out), e.g. it's de rigueur

to practice 3X a week and twice on weekends. They work servos harder than mere mortals and it's because of them that we make the rugged foundation of this marvel a CNC-machined case. Beginning life as a solid billet of 6061-T6 aircraft aluminum, when we're done it's a work of art.

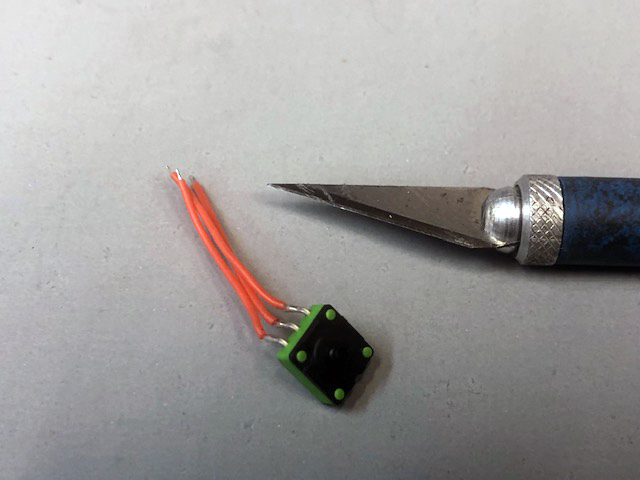

In fact, the DS85CLHV servo is

ideal for 48" 3D models, but because it outputs 5+ lbs of

force, then it means you could actually install it into a .40- .61 size model, maybe even larger depending on how you fly! At its heart is a incredible creation in miniaturization, a high performance coreless motor!

Basically, this servo has been expressly

crafted to meet your needs whether you're a beginner looking for your

first set of high quality submicro servos, or an experienced sportsman who attends

several fun flies each summer, or an

all out pro.

DETAILS:

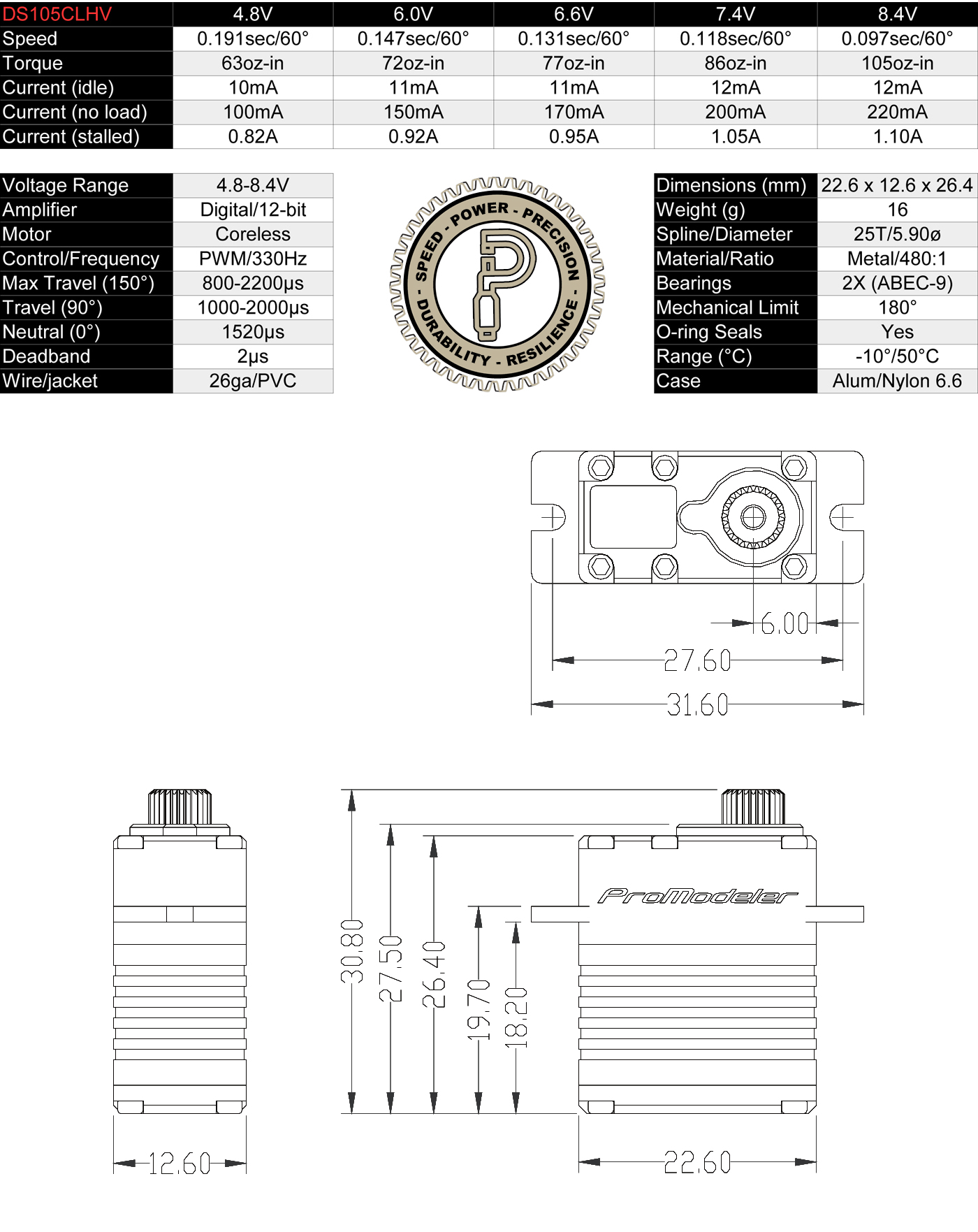

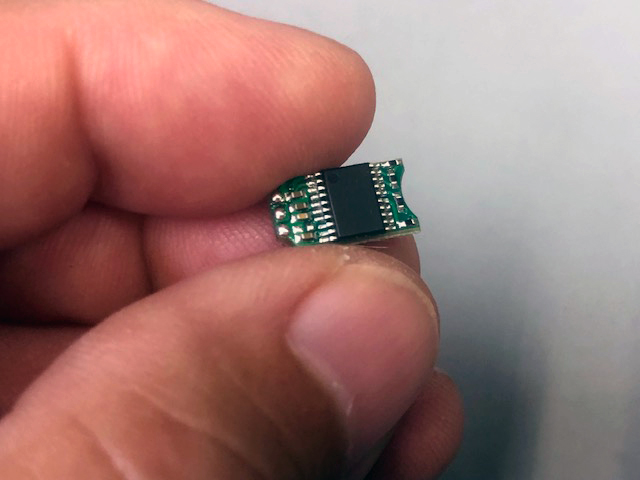

If

you're an electrical engineer you'll immediately notice we protect the PCB

from vibration with a conformal

coating instead of a little square of foam rubber. Referred to as

potting compound on the civilian side, we call it monkey-snot because

it's such a sticky mess to apply. This stuff is applied to the PCB and

oozes between components and once it sets is what lets our servos thrive

in harsh high-vibration environments. This is an aerospace-grade

technique and it makes ProModeler servos more valuable.Anyway, this is without question the smallest motherboard we've ever created and it's so small it about the size of you pinkie's fingernail, maybe smaller!

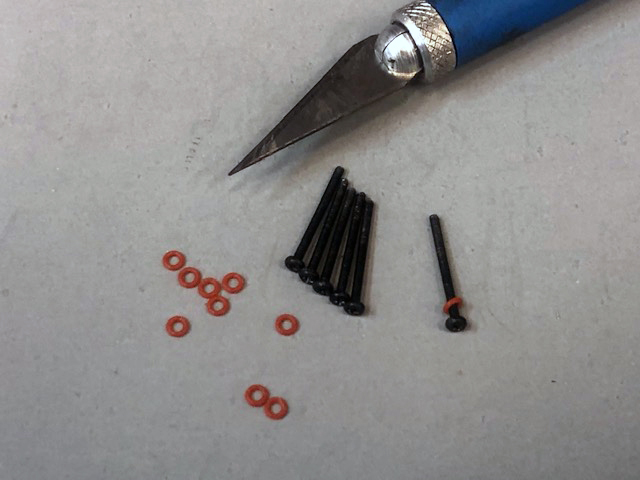

Another area where a ProModeler servos stand out is protection from

environmental contaminants, typically dust,

water, and exhaust-oil. The assembly of the DS85CLHV is protected with

o-rings - basically at every opening - even beneath the screw heads! We

all know how pernicious water can be with respect to penetrating where

we don't want it so this detail helps make ProModeler servos better. It's a no brainer . . . and these o-rings are microscopic in size!

In learning how well the DS65CLHV servo is made you'll understand why it's the sub-micro servo that expert modelers select the most for a

wide variety of sport and scale models. For example, ever taken a servo apart? The metal gears rotate on steel shafts. The end of the shaft fits in a hole in the case, what's called a pocket. In cheapo servos, the steel fits into a plastic pocket but in a ProModeler servo, there's a brass insert reinforcing the plastic. Basically, we produce ProModeler servos with the expectation of a service life measured in decades!

USE CASES:

So

who

uses these servos? In light of the MIL-SPEC and MIL-STANDARD test

methods, you won't

be surprised to learn the government has driven a lot of our product

development. They're our biggest customer. So are universities, plus

commercial UAS operators in agricultural and pipeline inspection ops.

We've branched out to the civilian world, so our customers now include

hobbyists.

This customer is often a highly experienced modeler,

but also includes savvy beginners who realize just because the servo

will first be used in 40-size trainer doesn't mean you throw them away

when you transition to a higher performance model. Anyway, you may use

this servo in a wide array of sport

and scale models - with wingspans ranging from about 48" on up.

SUMMARY:

We believe finding another that

offer everything these do is impossible to the point we believe there

isn't a better servo available for any amount of money on the planet.

Period. No other servo offers

this level of power, precision, quality, plus tank-like durability (and

nobody else lets you completely

rebuild them yourself). So if you're

an experienced modeler, and if you are mechanically 'ept' this is yet

another consideration (if you can do

basic soldering but naturally, you can also send them to us for R&R

if

you aren't comfortable doing these things).

Better

components. Better servos. The formula is simple. Decisions regarding

what goes into ProModeler servos aren't made in accounting to optimize

price and profit, but in engineering. We feel this is the best

sub-micro servo available. Add a set to your cart -

you're going to love them!

Overall Customer Rating of 1 Reviews: