As usual, what got me started on this servo recommendation for the Flex Innovations Mamba 120 was a customer reaching out for my thoughts regarding servos for this beast of a model.

As it turned out, after he built it (but before sharing photos with me), he got talked out of the model by another of our customers. Then if not the very next day, maybe the day after, another of our existing customers reached out inquiring about servos for one of these things, also!

So I jumped into my sent messages figuring to copy-and-paste the information but unfortunately, because I had inadvertently deleted sent messages (I'm human and have feet of clay), the information was gone like it never happened. So I began putting the information together once again (and believe me, there's a fair bit of work in sussing these things out because I don't just wing it).

Instead, where possible I use my own flying experience, and if I lack that with the model in question (or one like it), then I reach out to my customers and ask. Ask what? Like if they're happy with their servo purchase, and do they maybe wish they'd done something different? Point being, our equipment recommendation is not just theoretical but involves real world experience where possible. There's actually more than a little work involved!

Anyway, somewhere along the way I decided . . . this time, instead of replying with an email, let's put together a full blown caseSTUDY. This, so the info is readily available for the next guy right on the website! Also, this means he benefits because he doesn't have to wait on my response to an email (and I benefit because I don't have to go through the exercise of saying the same thing over and over via copy-and-past from an email). After all, isn't this precisely what computers are for, to save repetitive work? Win-win!

So here's what he asked, and my response. It's offered in hopes you find it useful for your Mamba 120 build!

Q. Hi John, I've fallen in love with a Flex Innovations Mamba 120 and need the best servos you make, what do you suggest? Oh, and I'm going to need servo arms, extensions, and a battery so if you'd let me know what else I'll need, I'll order that stuff while I'm at it. Thanks!

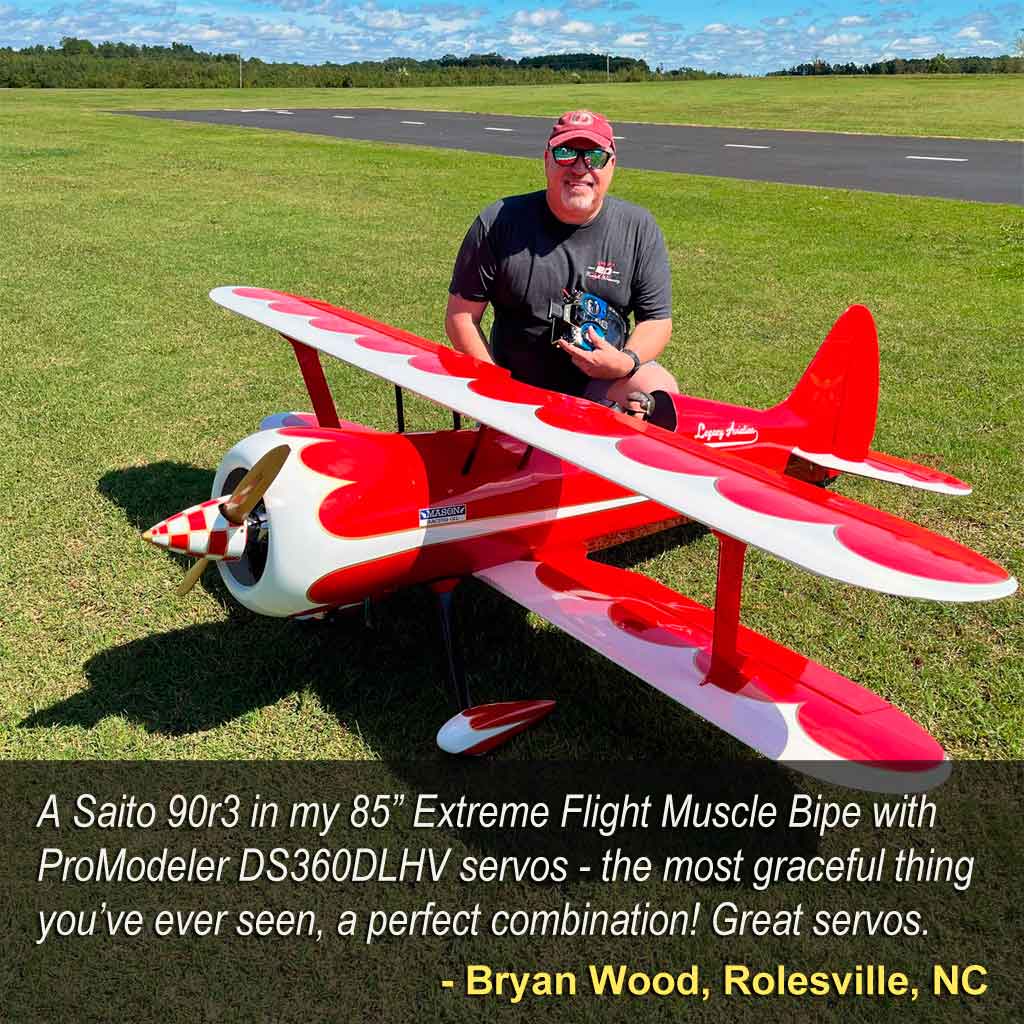

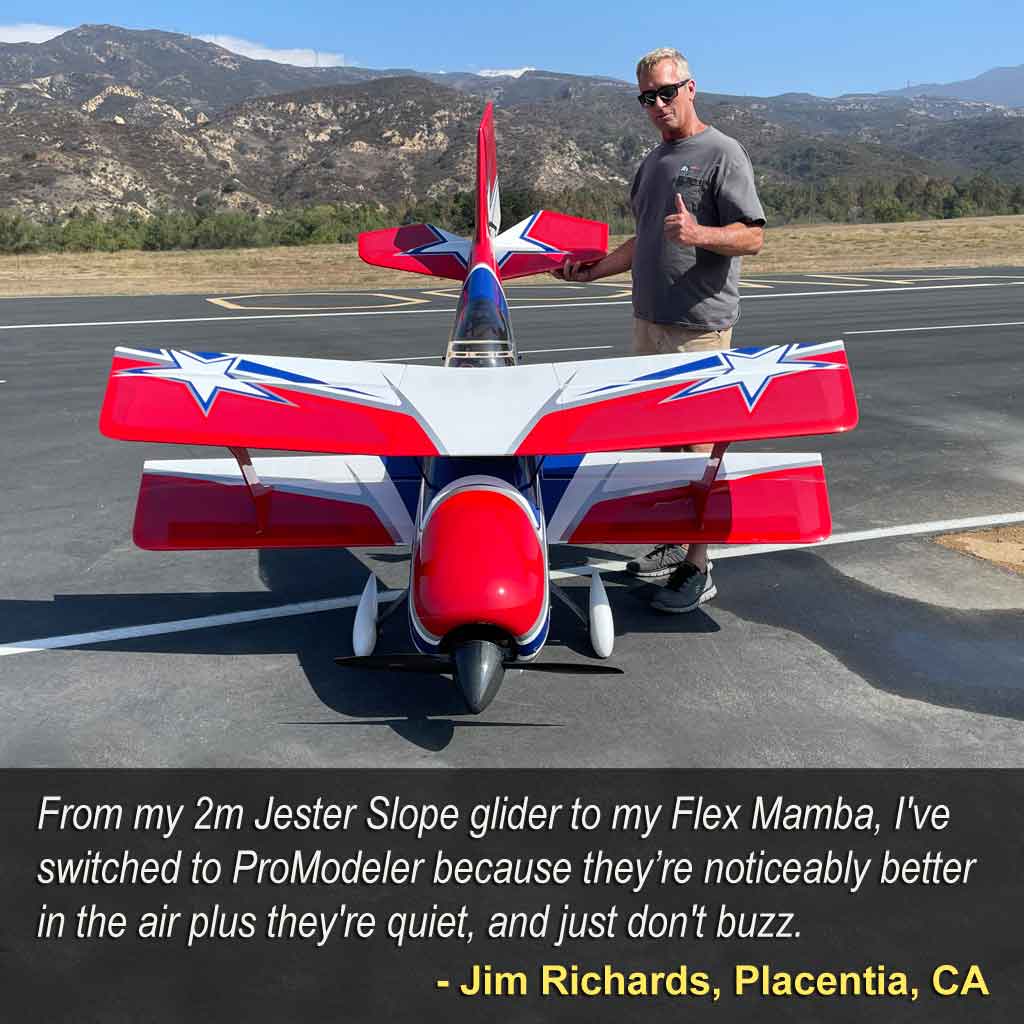

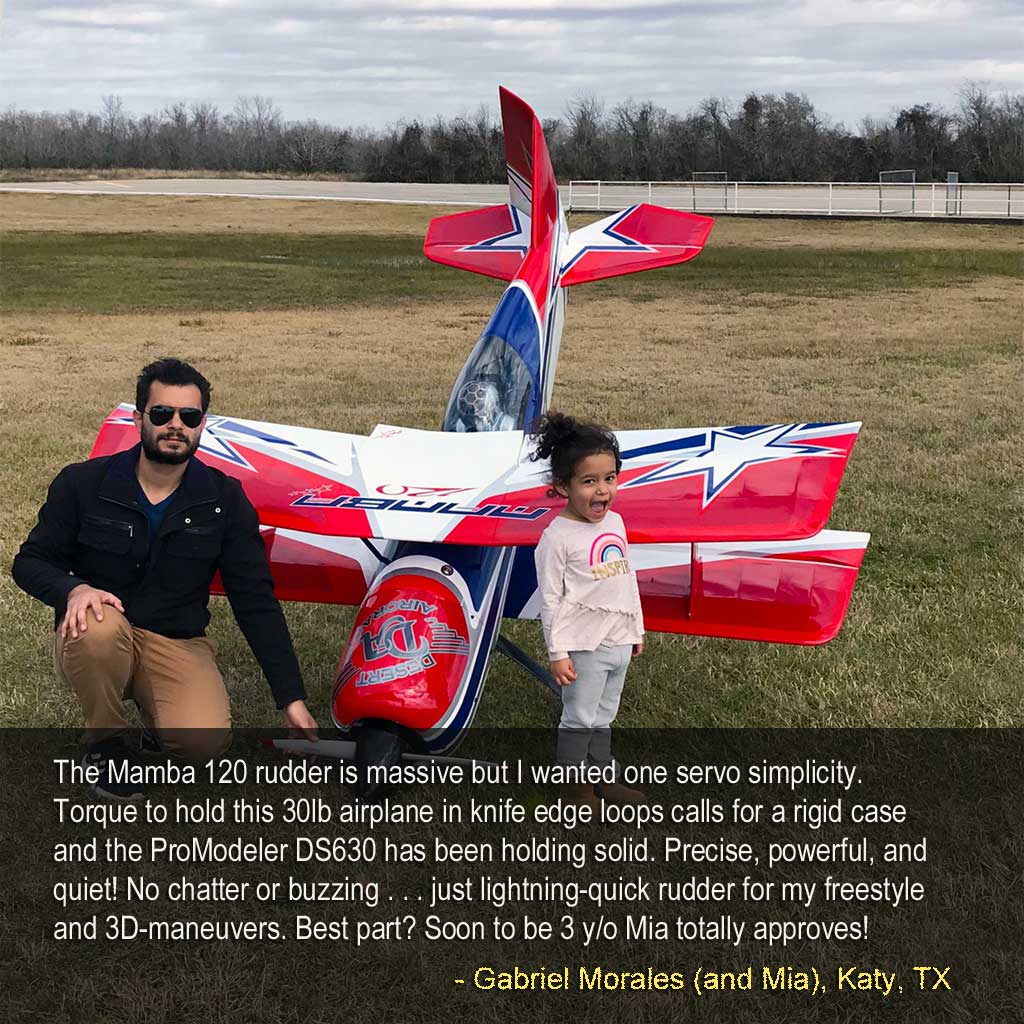

A. Hi Gabe, glad to hear from you. I trust your CARF Extra with DS1155 servos is still doing well, and this is why you've reached out once again for servos for your Mamba 120. As it happens, you're not the first to fellow inquiring about the best servos for a Mamba 120 and thus, I've helped several others in setting one up (also the smaller 70cc version). Anyway, let me dig out the info and I'll get back with you.

Background info

As you know, the Mamba 120 is a product of Flex Innovations. And these days, that's synonymous with Quique Somenzini.

As background, I first met Quique and his Dad in Costa Rica back in 1994 at Julio Pastora's fabulous international fun fly. Even then, the young Argentine was a flying sensation!

- Quique in 1994, a super nice young man with his dad - a father-son flying team

What was he like? Well, with cool as a cucumber demeanor and killer flying skills, I was actually more impressed with just how nice and approachable he was. Basically, the total opposite of a self-important prima donna if you take my meaning.

So fast forward about 30 years and he's now living in America (working first for Horizon, but now for himself at Flex). Wanna know what I especially like? This means a purchase from Flex Innovations goes to a small businessman working his tail off to create jobs and striving to live the American dream!

And you know what hasn't changed? He's still the nicest guy you could ever hope to meet. As for his flying skills? Yup, still top notch! What's more, because the Mamba 120 is his design, when you buy one you get the know-how of a truly expert pilot/designer . . . and it shows.

Equipment recommendation

So here's the thing, there's no *one* best servo for this model. Means there's a decision to be made on your part (because I don't really know you). So because we offer a range of servos, all of which are quite suitable, the decision you'll be making is based on a) your self-assessed flying skills, and b) your available budget.

So which servos are best for you? Well, as always . . . it depends!

First up, because it's a biplane, you know there are a butt load of servos in this aircraft. There's one for each flying surface. So that's four for ailerons, two more for the elevators, and one on the rudder. Plus throttle. Makes eight servos, total. Maybe nine if you like using one for choke. Moreover, I'm going to make equipment recommendations for three different set ups. And not just servos but servo arms, plus extensions, and batteries, too.

The three are the sport pilot, an expert pilot (IMAC type maneuvers, or mild 3D), and for the seriously proficient XA-pilot, the one who is maybe the 2nd coming of a Jase Dussia (flies it like he stole it and is seemingly trying to rip the wings off).

Equipment for the sport-pilot

Servos for the club level or sport-pilot are ones for the guy who loves the looks of this Mamba 120, but isn't really into Harrier rolls, and such. His repertoire may include slow rolls, loops, stall turns, Immelmans, Cuban 8s, and inverted flight. 3D? Nope, not his 'thang'.

Moreover, while he can afford whatever he wants, he's also savvy enough to know the only place he'll feel the difference between the sport-pilot recommendation and servos for the 2nd coming, is in his wallet.

So instead of our fastest and most powerful servos, because his skill set is solid, he wants a solid set of servos *but* he doesn't want to torch his wallet,

either.

Our servo recommendation is;

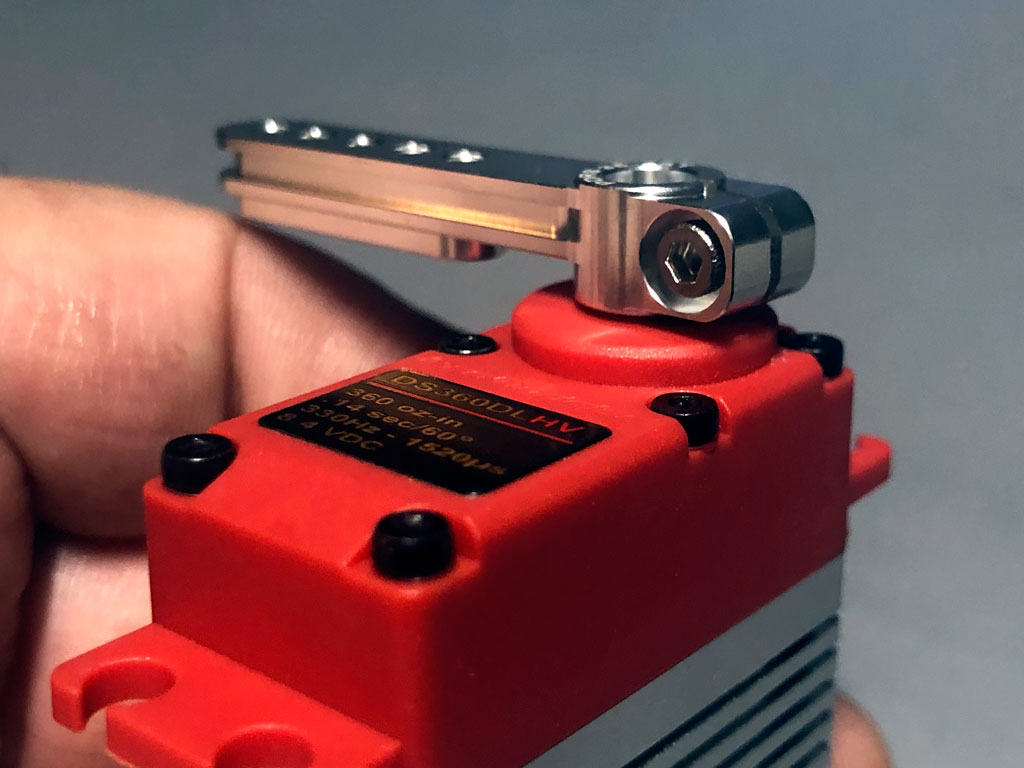

- DL-series are equipped with a durable all-steel gear train, and meet three MIL-STDS

Our servo arm recommendations are a mixed lot.

Basically, you'll need the same ones for the ailerons and elevator surfaces, but a double arm for the rudder, plus one for throttle (and maybe choke). Major point being, you're not using the same servo arm for everything. And because this model goes north of 29lbs, they need to be made of alloy, and not some el cheapo cheesy-ium but Alcoa 7075-T6 aircraft aluminum.

Ours are CNC-machined from a solid billet, tapped for bog standard M3 hardware, and feature our innovative I-beam design for strength. Best of all, they're thick enough you can forget needing to double nut the balls in place. That, and they clamp to the splined output shaft for the best security possible.

- PDRS35-25T has mounting points at 15, 20, 25, 30, and 35mm

Most importantly for a sport pilot, these are long enough to snap the model but not really long enough for an aggressive 3D setup because yes, you can opt for our longer arms and set it up for the benefit of the peanut gallery *but* if you really want the model to be smooth, then with the longer arms you'll be forced to give up resolution by dialing back ATV and add expo just to have a flyable model. So why use overly long arms in the first place if your goal is a smooth flying model? Of course, you're the customer so do as you please, but this is our recommendation.

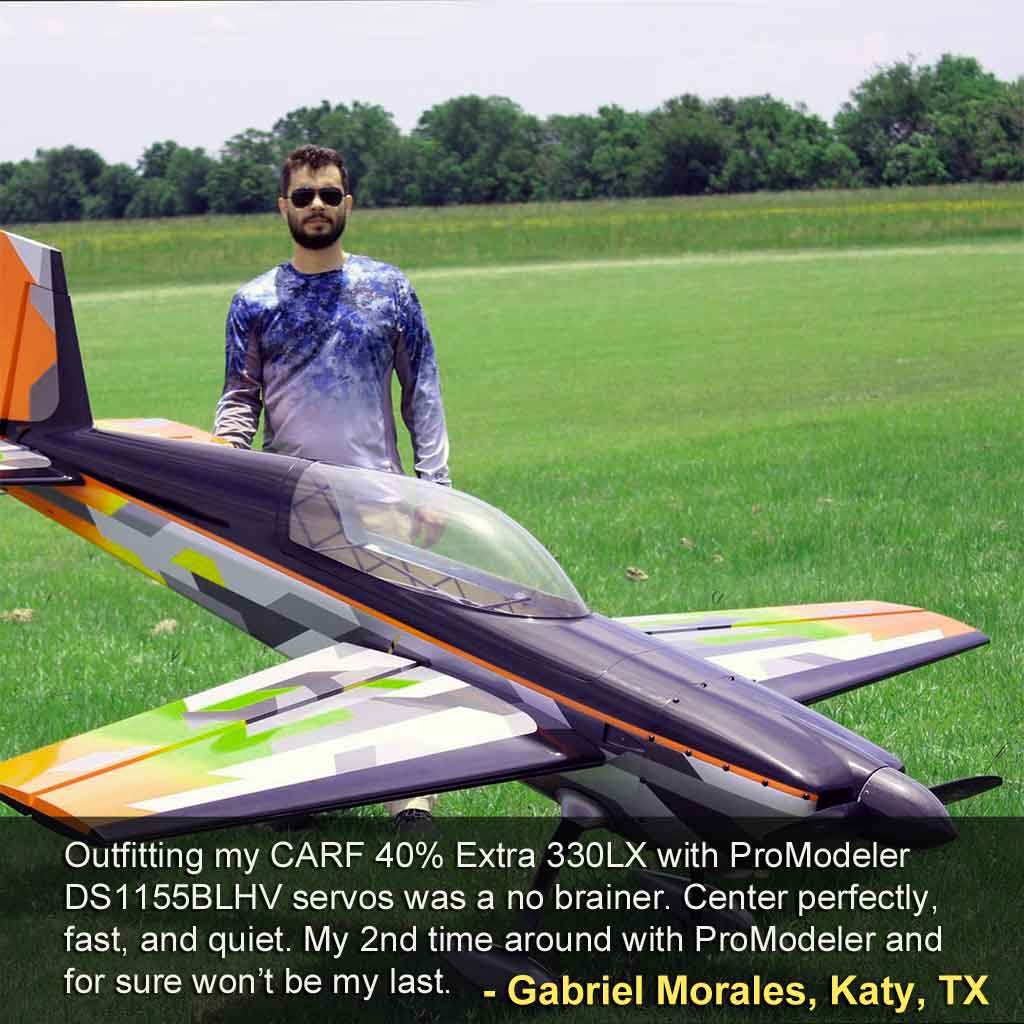

Note, while I try to speak with Mamba owners, I'm not going to ignore pilots of a similar model, like this 85" wingspan Extreme Flight Muscle Bipe. Why not? It's because these fellows also have good solid info to share with us.

- Not a Mamba 120cc but a similar size model

Expert-pilot

Next up are servos for the expert pilot. This guy is good - seriously good. So good sometimes he's called on for noon-time demos at local fun flies! He's also quite often the guy fellow pilots ask to test fly their models.

As for his skill set, they include IMAC maneuvers and mild 3D like falling leaf, blenders, and torque rolls. What's not there? The harsh high-speed maneuvers favored by some pilots. Maneuvers which require all the torque our most powerful servo can develop. After all, if you're not the second coming, equipping your model as if you were is just a waste of money. Of course, you're the customers, these are just suggestions.

Our servo recommendation is;

- DS505/630/930 are all built with all-steel gears and steel hardpoints in the alloy case

Now for something slightly off the wall

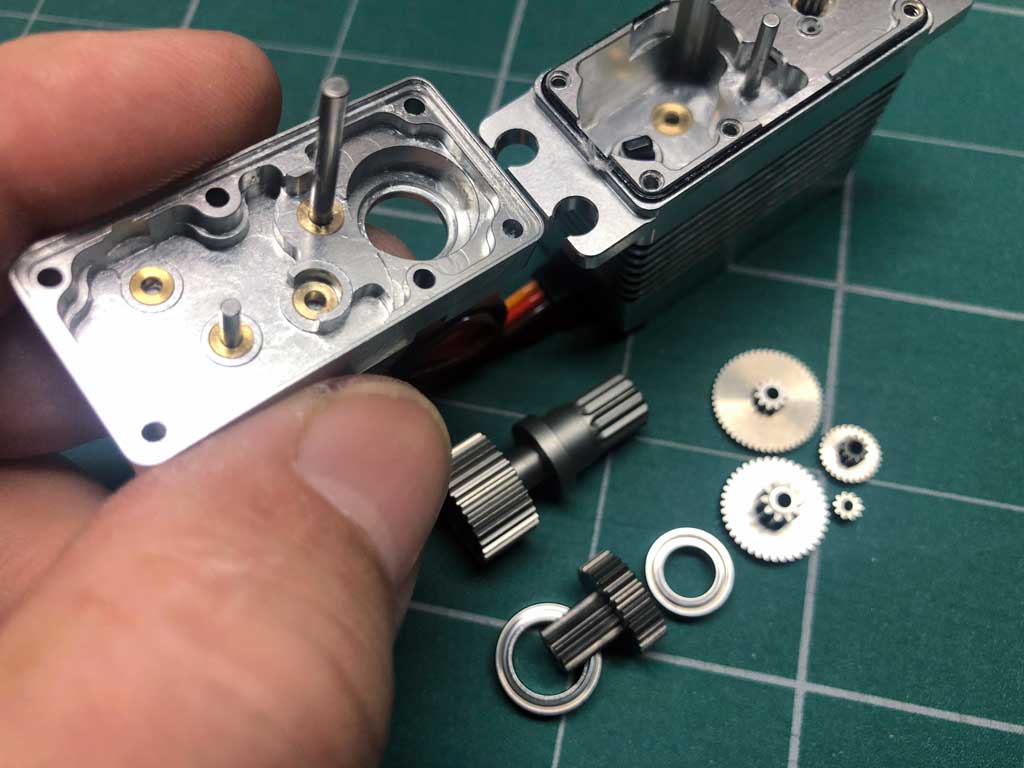

I'm going to share something with you, which you may find unusual, an article on repairing our DS505 servo. By the way, the DS630 and DS930 are built the same way so if you've seen the inside of one, you've seen the inside of all three. In fact, the DS505 and DS630 are the same servo other than the motor.

So why am I sharing this? Simple, it's because nobody else shares details about how their servos are made, or what may go wrong. Us? We know only God is perfect and the rest of us are doing the best we can. So I offer you this in the hope you find it to be an interesting read.

And note, as usual, these links open in another browser tab so you don't lose your place here.

Our servo arm recommendations are a mixed lot.

Again you'll need the same arms for ailerons and elevator surfaces, but a

double arm for the rudder, plus one for throttle (and maybe choke).

That, and they're long enough for mild 3D and IMAC but the model is really set up more with an emphasis on smooth instead of hard aerobatics.

If you're wondering why the polymer servo arm for the throttle/choke, it's to do with damping vibrations to the potentiometer. An alloy arm feeds them straight into the pot so we want to head that off before they lead to damage. Review this article for more information.

Equipment for hard charging XA Pilots

Finally, our recommended servos for the second coming of Jase Dussia - an off the wall pilot, capisce? This is the guy using the Mamba 120 to perform rolling Harriers down on the deck, torque rolls from the deck, climbing to 100', and then slowly rolling all the way back down to eye level. His skills are off the charts as he performs crankshafts at 20', rolling circles that seem to blur, as well as the Wall, and anything else you can name (and some you can't).

Our servo recommendation is;

ProTip: ProModeler model numbers means something in plain English. Here's the code;

- DS = Digital Servo

- xxxx = Torque rating in oz-in

- BL - Brushless motor

- HV = High Voltage (to 8.4V)

A word about servo motors

Also take note, servos for XA-pilots as well as the expert are for

ones with brushless motors whilst for the sport-pilot we suggested

economical servos with iron pole motors since he's not performing the

same kind of XA-maneuvers that need the servo to move a surface in a

gnat's whisker of time.

So just like Clint Eastwood in the role of Dirty Harry, a

man's got to know his limitations. Buying fast servos just for the joy

of it is fine if you have money to burn but unless your money grows on

trees, you need to be smart about your servo purchases.

Also, if you don't know diddly about servo motors and what makes an iron pole different from a coreless or brushless motor equipped servo, then review this article because we cut motors open with the lathe. Why? Expressly to show you what's inside that makes them different!

Construction

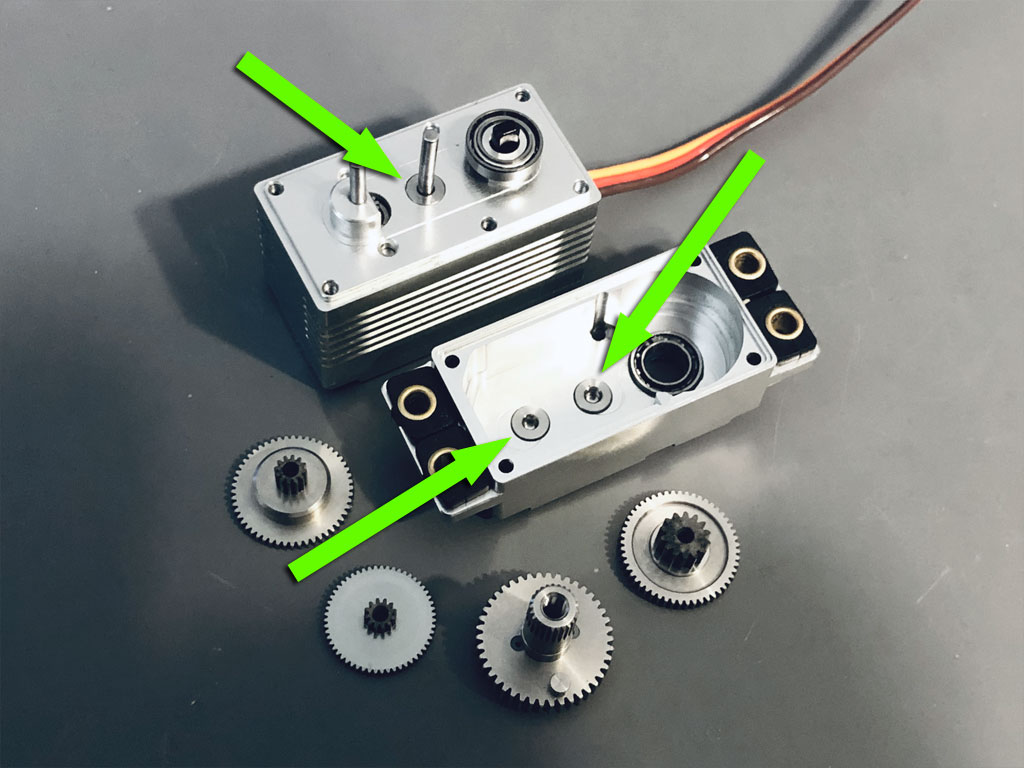

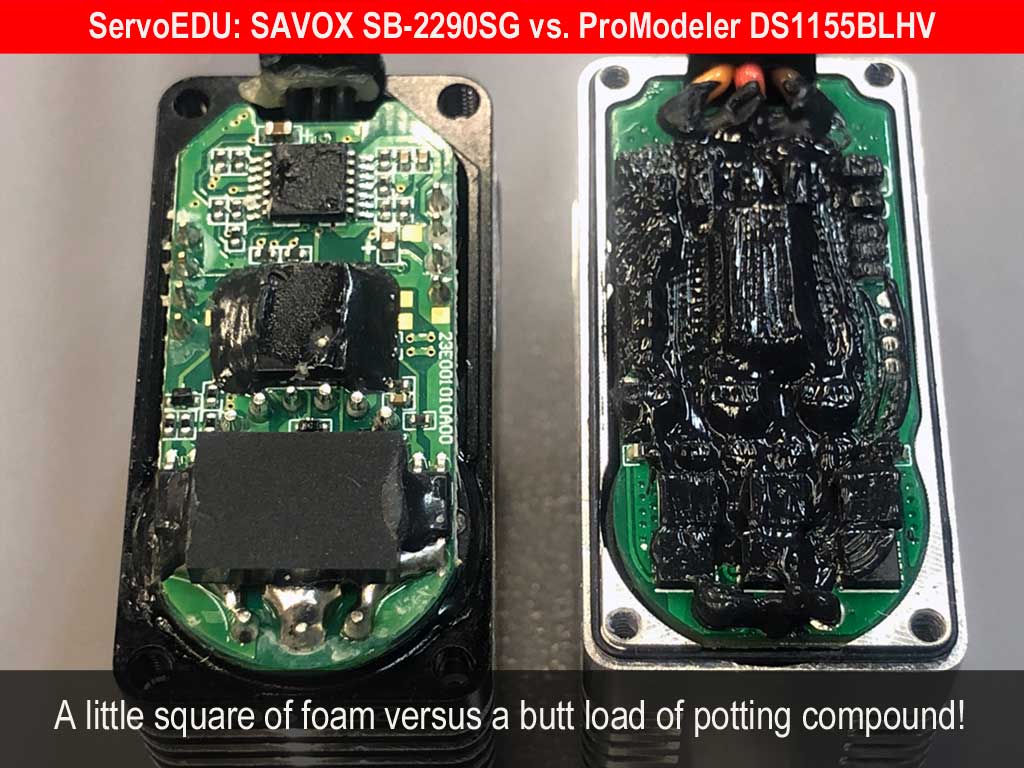

We take pride in our servos. Enough so to show you the guts instead of just the outside. For example, our BLS2 servos (what we recommend for pilots proficient in XA-maneuvers) are built to a higher standard. They're just more ruggedly than competing servos. And it shows.

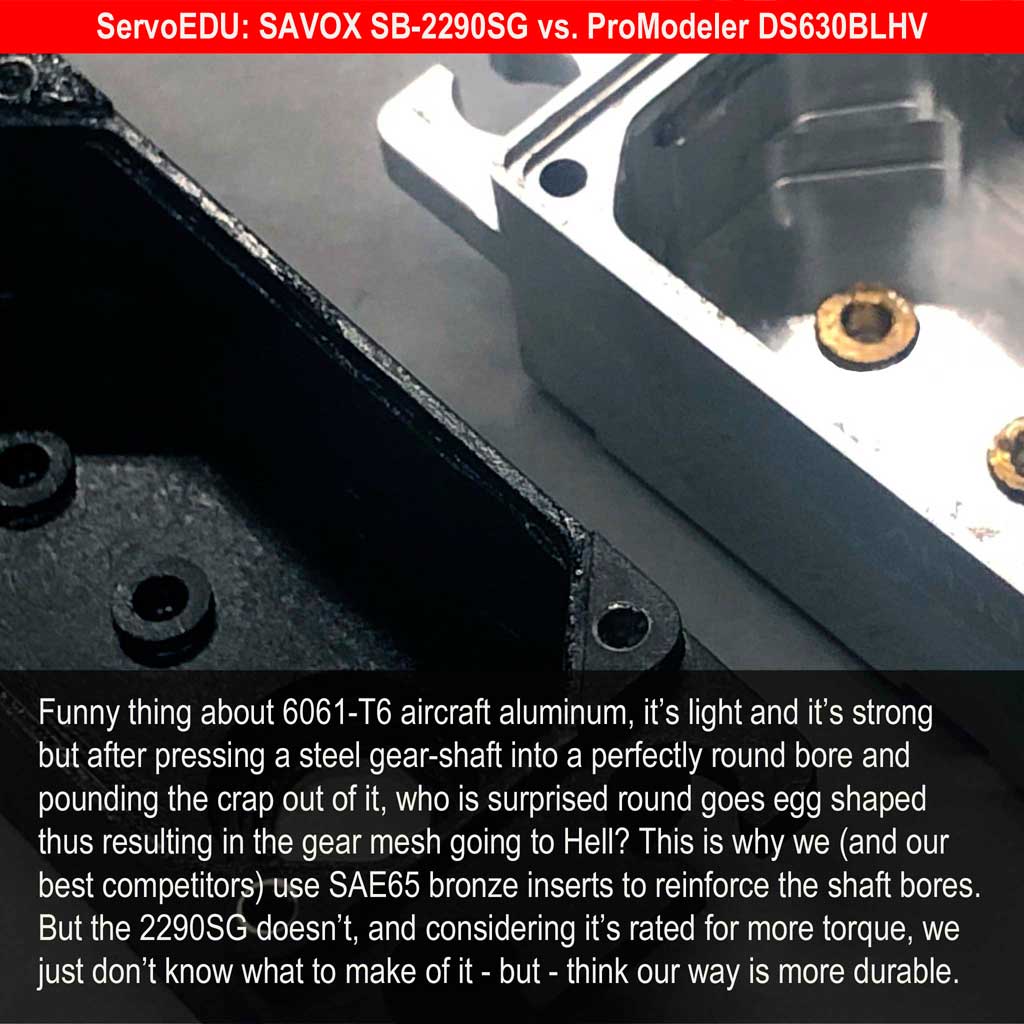

Since talk is cheap, we buy theirs, disassemble them and show you. The Savox SB-2290SG is a great example of a popular servo that's well regarded for good reason, it's a pretty good servo. But surprising nobody, we think ours is better.

Proof? Eyeball the next few photos where we show you ours has larger bearing, larger gears, larger diameter shafts, and more. Added to which, ours meet three MIL-STDS.

Also take note (in the next photo) of the use of hardpoints within the alloy of the case (where the bores for the shafts are fitted). The purpose of these is to spread the loads so when a servo is stressed over and over and over again, the bores don't become egg-shaped. If the holes aren't round, then the gear mesh shifts slightly, understand?

Thing is, once this happens, because aluminum doesn't heal, the servo is toast and gear wear accelerates. If you've ever wondered why in Hell you can't get more than a season out of a set of servo gears, this is why!

Worse still, buying a new set of gears is a temporary fix because the root of the problem is the case! So to make it like new again, you also need to replace said case. This makes the repair uneconomical. By design? Not for us to say but that's what it amounts to.

- Note, this photo is from a few years back, we switched to steel from bronze for this servo

But there's more, a lot more, like bearing size. Ours is larger so once again, we're spreading the loads more resulting in lower pressure loadings and thus, we're better protecting the case. Or put another way, protecting *your* investment!

And it's true, we make a big deal about our servos meeting MIL-STDS but shock and vibration are a big deal to our military customers. Maybe it should be a big deal to you, also. Especially when there's maybe $3000-4000 riding on things, eh? So we're more generous with the potting compound, too.

Our servo arm recommendations are a mixed lot.

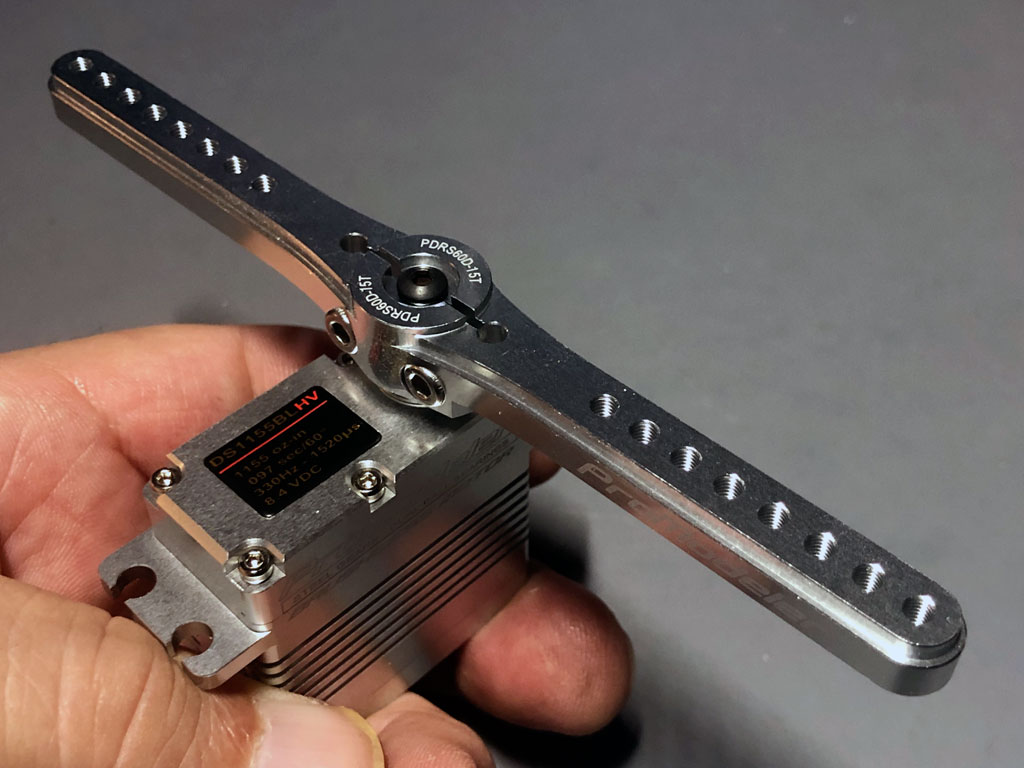

Again you'll need the same arms for ailerons and elevator surfaces, and a double arm for the rudder, plus one for throttle (and maybe choke). This one is a tad over 4-5/8" ball-to-ball to deliver the monster throw required for gonzo nuts maneuvers.

For wild 3D, you want our longest arms. The whole set up is the opposite of a smooth IMAC style or mild 3D. Instead, this setup is for trying to create enough throw to engage in full on post-stall maneuvers where there's +30° of throw.

These arms are MUCH too long for mild 3D and IMAC because the point of using these with a model is to get loads of throw. Precision goes out the window when you're performing the harshest of aerobatics. And because of how long they are, then you'll see the gear train backlash magnified at the ends of the control surfaces (not that it changes based on servo arm length). So what you're seeing is because of the use of long levers. Taking it to an extreme, if you used a servo arm 36" long, then you'd see more than an inch of movement at the end (e.g. the backlash), but it's the same servo, so the backlash is unchanged (so it's a visual artifact).

What's more, these super long servo arms are a terrible choice for an IMAC pilot because the model will lack precision, which is of no concern for flying the hard XA maneuvers hard chargers perform, capisce? So don't let some idiot who doesn't know his ass from a hole in the ground see the backlash magnified due to long levers at play who doesn't understand they simply change perception - heads up - this is down to physics!

Our recommended extensions

We make the same recommendation for XA-pilots as for sport and expert pilots, the thickest gauge wire that can be crimped into the 3-pin DuPont connector, which is 20AWG - this to minimize voltage loss. Learn more reviewing this information:

Moreover, these extensions all have twisted wire instead of flat wire. Why? To help resist stray RF (if the ignition module's shielding ever begins going south, it begins to broadcast a signal that interferes with your receiver). Twisted leads resist this interference better than flat wires. Again, not opinion, physics!

And before I forget, let me mention the insulation used is that super supple silicone which resists abrasion and turns corners easily. With a high strand count, too making these the best money can buy.

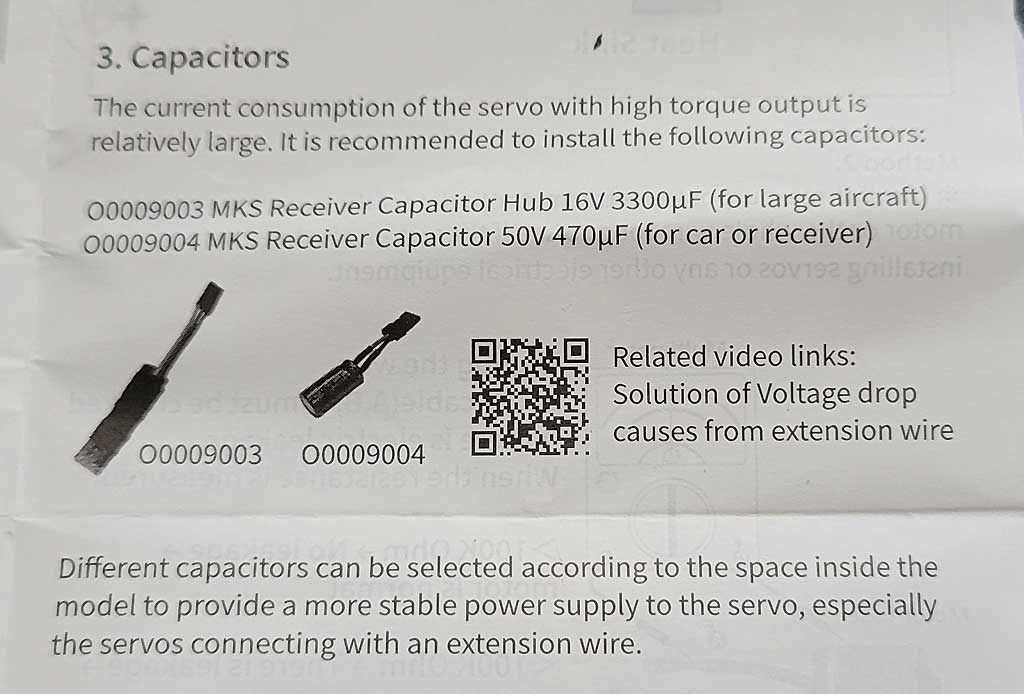

ProTip: whenever an extension exceeds 30" you'd be wise to add capacitance. How? Simplicity itself - by using a Y-harness and a capacitor. Learn more by following this link. Capacitors

And note, added capacitance isn't about just our servos, it's for all servos . . . any brand because again, physics! Note; we're not alone recommending this, so do MKS, which are another fine quality competitor . . so heads up!

Batteries

Battery pack wise, with a lot of servos, it means high current flows. You'd be wise to use a pack with two leads feeding the receiver since each lead is worth 3.5A continuous, or 5A intermittent.

Capacity-wise a 5000-6000mAh is enough and we offer both LiIon and LFP chemistry. If you're flying 3D, then you want the highest voltage and that'll be LiIon so the B2S5000 is the one you want.

Note; we've stopped handling LiPo and LiFe packs for avionics and stick to the more rugged cells built within cylindrical metal shells. Why? It's because we all make decisions regarding risk and we'd rather not be associated with soft side packs. The reason is due to the risk of fire.

Way we see it, LiPo a worth few tenths more voltage (which we can measure on the workbench but isn't enough to notice in the air), which we judge not worth the risk - not to us, and not to our business. That said, opinions are like bellybuttons in that we all have one . . . when it comes to avionics, use cells protected by a metal shell, only. This is our best advice regarding good practice.

Next, if you're a sport pilot, then quite frankly, LFP cells are much easier to live with because you don't have to take them down to storage mode after you charge them (like if a honey-do suddenly interferes with your plans to go fly). So for you, the B2S6000 is the pack you want.

As with the code regarding servo model numbers, the one for batteries it's also easy;

- B = Battery

- 2 = number of cells

- S = Series construction

- xxxx = Capacity in mAh

Last thing, I mentioned using 2 leads coming off the battery. These articles explain more.

Open them with your phone and you have reading material for when you're on the throne!

Also, regarding the battery for the ignition, figure 1000mAh per cylinder so for a two-cylinder engine, use a B2S2500 and you have a skosh to spare!

Conclusion

Wrapping things up. The right servos for you may range in price from 50 bucks to more than 3X as much. All our recommended servos meet MIL-STDS for shock and vibration as well as environmental protection by using 13 o-rings and conformal coatings on the circuit board. Along with 1 million cycle Noble MC1 potentiometer to ensure great centering, and all-steel gears for great durability, the difference in price between the $50 servo and the most costly is down to your requirements regarding transit speed and case construction. Put another way, horses for courses!

Major point being, even our $50 servos speak for us, because there's nothing cheaply built about *any* ProModeler servo. In closing, our best advice remains, use your head instead of emotion and don't buy more servo than you need! If in doubt, pick up the phone and ask us.

Any further questions, suggestion for this article, etc. then just reach

out to me at 407-302-3361, or via email: info@promodeler.com