We field a lot of questions regarding the splines on our servos. Below are examples and their answers. And if you're too busy to read this, then we'll cut to the chase with a TLDR;

ProModeler servos use a 25T splines (Futaba-compatible), plus an M3 machine-thread bolt.

Q. How many splines does ProModeler use on the servo output shaft?

A. Our servos have 25T splines.

Q. What size screw fits the output shaft?

A. We use the common as dirt M3-thread you can buy in a hardware store.

Q. What's the output shaft diameter?

A. It's 6mm OD (nominal), which is roughly 1/4".

Q. Are ProModeler servo arms compatible with Futaba?

A. Yes.

Q. Was it just to copy them?

A. No, not really.

You see, when cutting splines for a 1/4" shaft, you have a choice of spline count like 22, 23, 24, 25, 26, or 27-teeth (ditto the broach for cutting the corresponding inside diameter for the matching servo arms). Thing is, when you choose an even number, flipping a servo arm around doesn't help with mechanical setup while an odd-count does.

This was once super important (back in the days before transmitters had a subtrim function) 'but' it still remains important for pros today.

Basically, it's important for pros who want to optimize the mechanical setup to reduce the amount of subtrim used in the transmitter. How? They're taking advantage of a trick involving rotating the servo arm on the shaft to effect a slight chance in center. But it only works with an odd-number of splines because with an even-number spline count, flipping the arm around 180° gets you nothing.

Thus, while the duffer doesn't know or care that an odd-number of splines gives an advantage for mechanical setup, for the serious modeler this can be a big deal. So if you've ever wondered what separates the wannabes from the pros, this is one of those things. It also explains why we didn't use an even number of splines, and also why we calculated 25T is the right number.

First, with respect to why we didn't use 23T (like another competitor). It's basically due to our experience that 23T results in too coarse an adjustment when you move the arm just one spline at a time. Especially for a precise setup! Hence, in our opinion 23T is inferior to 25T for a quality mechanical setup.

Second, with respect to using 27T, then another problem comes up, not that it's too coarse but that because the individual teeth being finer (smaller) the assembly become a little too weak. While 27T would be OK for a 100oz-in servo, for servos outputting over 300oz-in (which some of ours easily do), then this becomes a big deal.

Thus, just like Goldilocks and the three bears, 25T is not too coarse, not too fine, but just right! And that it also means our servo arms are compatible with Futaba is no bad thing in itself because it opens a wider universe of products for our customers. Win-win!

And note; even some manufacturers that historically used 23T have come around to recognizing our 25T spline is superior, which is why they're switching their new production to 25T . . . fact!

Anyway, below is an example of the practical application of using the 25T spline to the benefit of your mechanical setup. Learn from it and take another step toward becoming a pro!

Ever put a servo-arm on the servo's output shaft and notice it doesn't fit 'square' to the case? Eyeball this photo below. Notice how the servo arm is slightly CW of neutral. The problem with this is you'll get asymmetrical throw. In this instance, a little bit more CCW than CW and this is bad because it may throw off how your model handles - either more to the left than to the right, or less up vs. down and this is bad because you usually want the controls to be equal in both directions.

However, there are exceptions. Like when you want to reduce down-aileron vs. up-aileron for reasons to do with adverse yaw. This is a special case and beyond the scope of this particular paper.

So if you notice the arm isn't square, usually folks next try shifting it by one spline in an attempt to obtain a better neutral position relative to the case. In the next photo (below), you see that even with a relatively fine 25T spline, moving the arm by just one spline results in the arm going from a tad too far CW to a little bit too far CCW (from neutral).

This is the point where an ordinary modeler goes into their transmitter and uses the sub-trim function. One of the differences between an ordinary modeler and a pro is the pro has another trick in his bag. But for it to work, the servo 'must' have an odd-number of splines (e.g. 23, 25, 27). Then all the pro does is flip (or rotate) the servo arm around 180°. Why? It's because this often results in the servo arm being much closer to perfectly square (neutral).

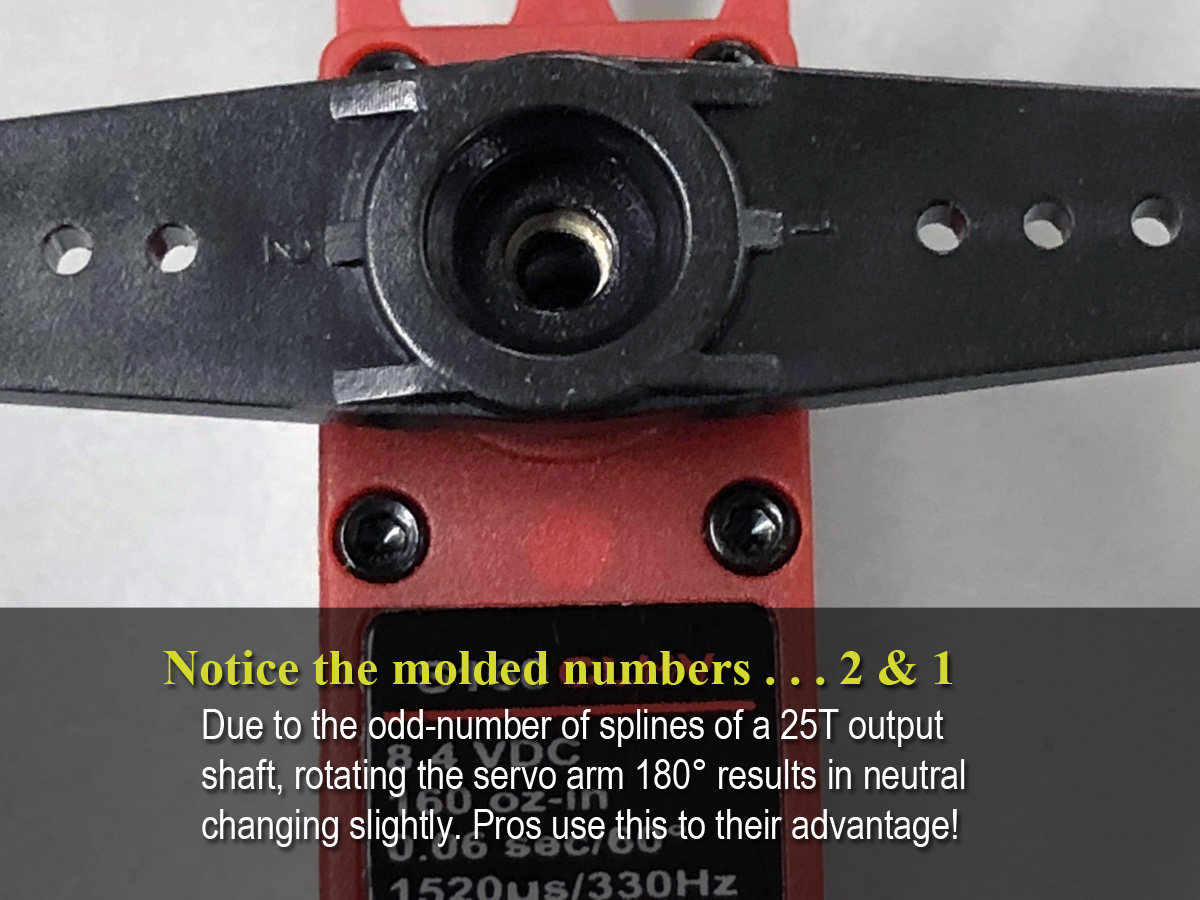

Note how in the photo below after flipping the arm around it's still not quite perfect. Granted, it's at an 'almost' perfectly neutral position, it's not quite there. Remember, the advantage of mechanical setup is it requires less (or sometimes zero) subtrim in the transmitter. This means fewer calculations for its CPU to keep track of. Big deal? Nope. But it's our experience the things that often separate the pros from the wannabes includes paying attention to the smallest of the details! Are we done? Not quite.

There's one last trick a pro has up his sleeve to try before resorting to sub-trim. Basically it's this; he'll try and take advantage of differences in the molds used for creating the servos arms because try as we may to make them all identical, only God is perfect. Thus, there are sometimes subtle differences between two otherwise identical appearing arms.

This just means if you have several of the same servo arm laying around, try swapping one for another because you may get lucky and find one that makes the mechanical set up better just due to how they're imperfectly molded! So you've learned yet another trick the pros use when working to fine tune things a tiny little bit. They use another of the same arm!

Finally, after all the tricks to achieve the best mechanical set up, it's time to use sub-trim. But if you're a pro at performing the mechanical setup, your model will have less sub-trim affecting subsequent programming.

By the way, to help you keep track of which horn is which on a servo

arm, notice the tiny numbers molded in near the base of the horn. These are also present on the 4-horn and 6-horn servo arms.