I received an incredibly insightful question via the fabulous Arrma Forum (if you've unfamiliar with it, then I strongly urge you to click this link and register an account - it'll open in a separate browser page so you don't lose your place, here).

Anyway, I'm using his query as the foundation for another EDU article because if this fellow is wondering this, then there's a fair chance others are wondering the exact same thing!

Note; his 'handle' online is abh16 so I cannot address him by name but regardless, this is how we got here . . .

Q. Is backyard bashing an application where these incredibly high quality (and expensive) servos are suitable? Or are they more suited to competitive racing, etc. where you need the best of the best? Like I don't buy a competition race-ready Porsche to drive around in New York city because it's overkill and I can't use its potential. Am I missing something?

A. To whether you really need to pony up for a ProModeler servo if all you're doing is bashing, the short answer is, and unsurprising to everyone who knows me . . . it depends!

Not what you expected me to say? Fair enough, but if you'll allow me the privilege, let me try to expand my thoughts a little bit because maybe I can share enough information to jump start your own thoughts and experiences. Meaning, I'll bring you to the point where you know the right answer for 'your' situation without 'me' telling you what to think or do.

- $60 on Amazon, better to buy once, cry once?

To try and figure it out, I went on Amazon and bought an SO45KG brushless servo for $60, which we'll put up to a ProModeler DS505BLHV

Why? Because we're willing to take on anybody, at any price point. America is our turf, we'll defend it from all intruders.

First impressions

Honestly, it's a pretty good looking servo, can't take that away from them. Both are water resistant, too. And steel gears. Lot to like.

From the outside, and based on the specs, it looks like quite a deal. However, the rest of the story comes into focus when we open it and look at the inside. Otherwise, it's an attractive looking piece of kit. Meaning it looks nicely made. However, right off I saw something important . . .

- This roughly 40W device has no cooling fins - yikes!

These things easily exceed 5A of current draw at 8.4V so using V*A=W then 8.4x5=32W and that's a lot of heat to deal with without cooling fins. Look, ever touch a 25W refrigerator bulb? Bugger gets hot, doesn't it? So believe me, the fins are 'not' decoration when you're making the kind of torque both of these servos make. Me? I suspect marketing won the battle which explains the large laser-etched 45KG on the side instead of cooling fins. Which is more important between promotional and performance is a no brainer and lack of cooling fins is an immediate downgrade because these things get hot when they're working!

So my first impression is pretty servo, but seriously, you've done away with cooling fins for the benefit of the marketing department? You really couldn't win the argument that propaganda (lasered logos) is trumped by shedding heat in a device created for performance instead of looks? Whatever . . . but that's a win right off the bat for ProModeler.

But let's delve deeper and see if all they have is a pretty face or the stones to hang with us. Learning whether it does or doesn't requires us to do more than dip our toes! We must look inside.

Fortunately, I have both the tools and a trained eye. So let me show you what's important to consider when you're examining servos. And remember, we've already found they don't optimize cooling, so it already doesn't bode well in the money-well-spent department, but let's keep looking.

- No cooling fins . . . yikes!

Note, as engineers, part of the process is to test the extremes. We do it in all regards we can think of to include boiling down abh16's question to the essential ask. And not too surprisingly, this immediately brings up another question. Here's the ask and the real question to be answered;

- Why should I fork over 100 bucks for ProModeler if for just $60, I get the same thing?

- To which the question is . . . do you 'really' get the same thing?

Defining the parameters

As was very astutely observed, bashing is different from racing. We need to know in what ways it's different, and does it matter in the real world.

Racing is typically on a closed course track. Surface-wise, clay is popular, but so is sand and plain old dirt. The borders of the surface are usually black plastic underground drain pipe (black 4" diameter ridged-pipe perforated by holes). That stuff is rigid but not really hard, so running into it with the rig rarely results in servo damage, but when it does, it almost certainly results in a DNF.

- This means Did Not Finish and that's especially bad because it means zero points.

- That, and you can't win if you don't finish! Duh!

So you're 100% right in assuming pro-level racers tend to buy a better class of servo. This, to better withstand the abuses dished out during competition. But does this matter in the slightest to bashers? And what makes a servo 'better' to the pros?

ProTip; beyond more rugged, another reason racers buy a better class of servo is for centering performance. ProModeler servos center within 0.5°and because we use genuine Japanese Nobel million-cycle potentiometers, it doesn't get any better at any price.

Begs the question, does better centering matter to bashers? Well of course it does because jumping is half the fun and repeatedly nailing a jump requires very precise entry, hence the importance of centering above strength or speed!

Bashing is an all-surface event. This means the rig may encounter grassy fields (and hidden gopher holes). In fact, critter holes include rabbit, prairie dog, groundhogs, wolverines, whatever! Plus there are also unimproved dirt surfaces, country roads, walking trails, etc.

Note; holes are generally hidden and pure murder on a rig as they can rip off an entire front suspension arm. They're tough on servos, too.

So unlike racing where conditions are controlled, bashing in the great outdoors means the rig may encounter further natural and man-made obstacles like tree roots, rocks, fence posts, etc. None of these have any give to them whatsoever.

Ditto cityscapes, where your rig often encounters objects like skateboard ramps (intentionally), plus concrete curbs, mail-box posts, potholes, fire hydrants, light poles, etc.

All of these being things you're better off avoiding with your rig if at all possible, trust me

Thing is, for whatever reason, and I know it seems strange to say this, but it's my experience these things have attractive powers. Said strange attractors are AKA . . . rig magnets!

Bad juju usually follows.

Before a military plan is put into action, they go around the room in increasing order of rank (meaning beginning with junior-most officers before ending with the commanding officer), each to opine junior-before-senior (so the juniors aren't unduly swayed by what the senior has to say) their thoughts regarding the plan. So here's how this will go (so that I can't be accused of telling you what to think); I'll ask rhetorical questions for you to answer, I'll also share photos, and only after you see what you'll see will I subsequently share my thoughts, fair enough?

Question #1 - riddle me this . . . in your judgement . . . in which environment are the obstacles more likely to be of a type that result in damage to the rig when encountered at high speed; the plastic drain pipe delineating the track boundaries, or the hidden holes, curbs, roots, ramps, and fence posts encountered by the basher?

Answer 1: __________________________________________

My thoughts go along the lines of; on the track there are no invisible holes, the flexible pipe absorbs most impact and as a racer, I'm prepared so I have a spare servo (meaning in a few minutes the rig is ready for the next heat). Not that I don't care that I broke it, but that I am prepared for the eventuality. This also means I send it off for repair while continuing business as usual. Top racers have three servos/car, so they install the back up, and still have one more backup while the broken one is sent off for repair. Ideally, said racer doesn't miss a beat.

Unfortunately, as a basher, it's unlikely I have a spare servo, so if I damage my rig, I'm done for the day/week, whatever. No matter what, this means you've blown your opportunity for a day/weekend of fun running your rig and basically, you're done. In our experience, few bashers keep spares.

Question 2 - can you buy spare gear sets, or is the price of the gear repair buying a new servo for another 60 bucks? Meaning, is it a throwaway? ProModeler offer gears, potentiometers, motors, whatever because we have a technical department . . . do they? And is this important to you?

Answer 2: __________________________________________

- Are spares important to you?

Question #3 - brings up the point . . . does your time playing with your rig have value to you, and thus, could it perhaps be fairly assessed a basher actually wants an even more toughly built servo than the racer?

Answer 3: __________________________________________

The contender for the throne

- As I'm fond of saying, you don't need to be an engineer to figure these things out, all you really need are your own set of Eyeballs Mark II.

- That, and the old saw about a picture being worth a 1000-words comes into play, so let's use pictures to tell the rest of the story.

Note; the 45Kg servo is a typical Amazon offering, meaning an import made in Eastern Asia. Is it a good enough servo for your needs? If so, then you're golden and you've saved $40. But if not, then you've pretty much pissed away your hard-earned money - are we agreed?

What comes next hits hard and fast, so lets go . . .

- Steel gears are what you want

So to my eyes the gears aren't stainless. Whatever. However a funny thing happened, I ordered the $60 brushless and received the $50 coreless. Not that it really matters because they're both rated the exact same and look the same inside other than the motor, but it's something to watch out for if you decide to opt for the el cheapo alternative.

Anyway, whether the quality of the gears matters to you, or not, is basically the question.

Question #4 - look carefully; does gear train quality matter to you?

Answer 4: __________________________________________

My turn; we spend a fair bit of time determining the best steel composition for our gear trains because all steel is not equal. Honestly? If I had to guess, ours are of substantially higher quality.

Gear train quality directly impacts how long the gear train will last before wear gets so bad you need to replace them, or they break. I'm talking about durability. And size matters meaning bigger is better.

- The finish is a good proxy for quality

Me? About the above photo? I'm prejudiced, of course, but I'm also highly experienced in gear material selection, and I know there are many available grades. To my eye these look distinctly toward the lower end of the scale. So in the eyeball department, I score this a win for ProModeler. Movin' on . . .

- With apologies to Wendy's . . . where's the beef?

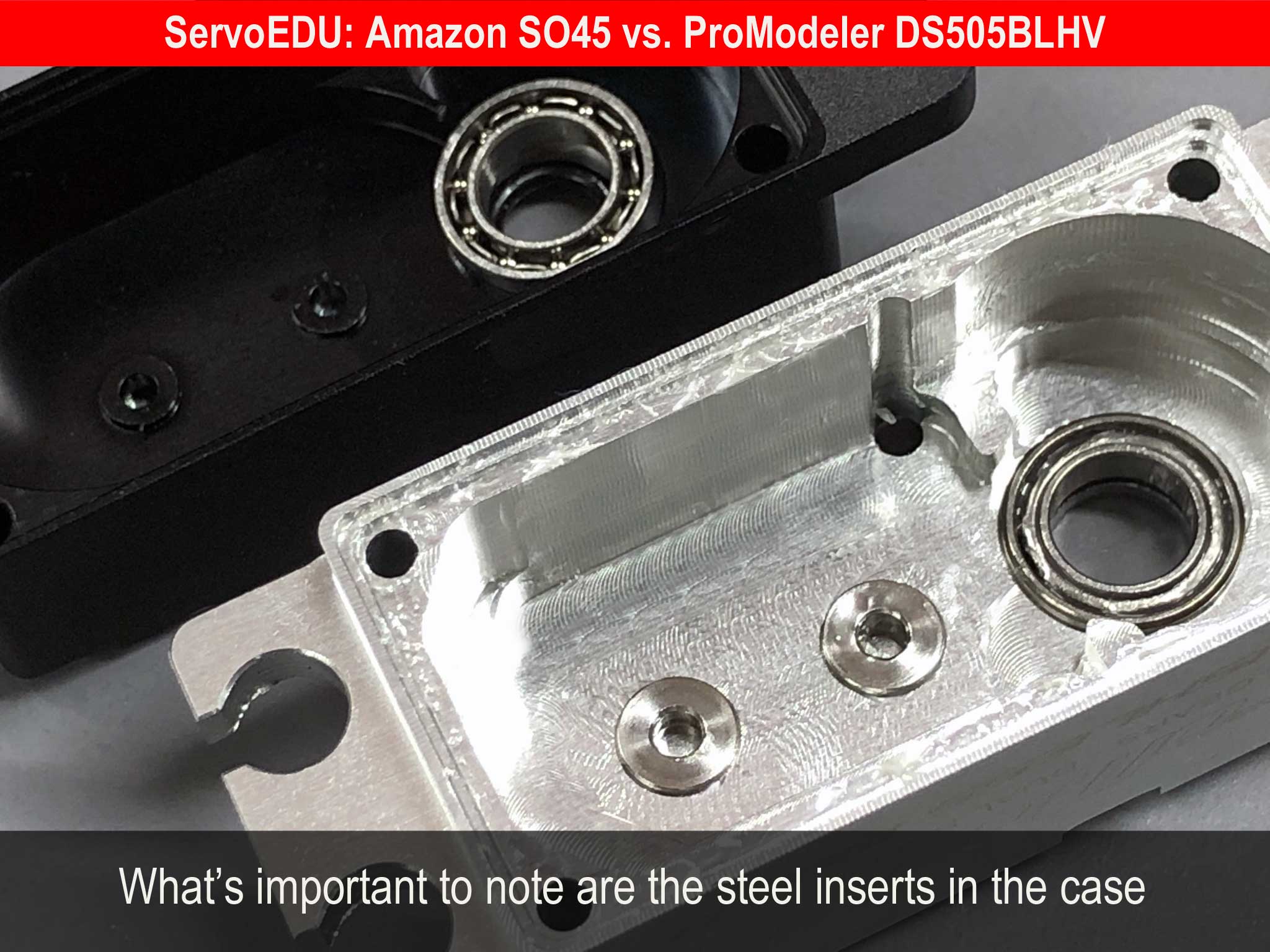

No hard points in their case! This is a big deal . . . we reinforce the case for a darned good reason. The steel shafts the gears rotate on will beat the ever living crap out of the aluminum case when under harsh loads. Remember, steel is hard and aluminum is soft. This matters. So now we're getting into engineering issues so the next question is this . . .

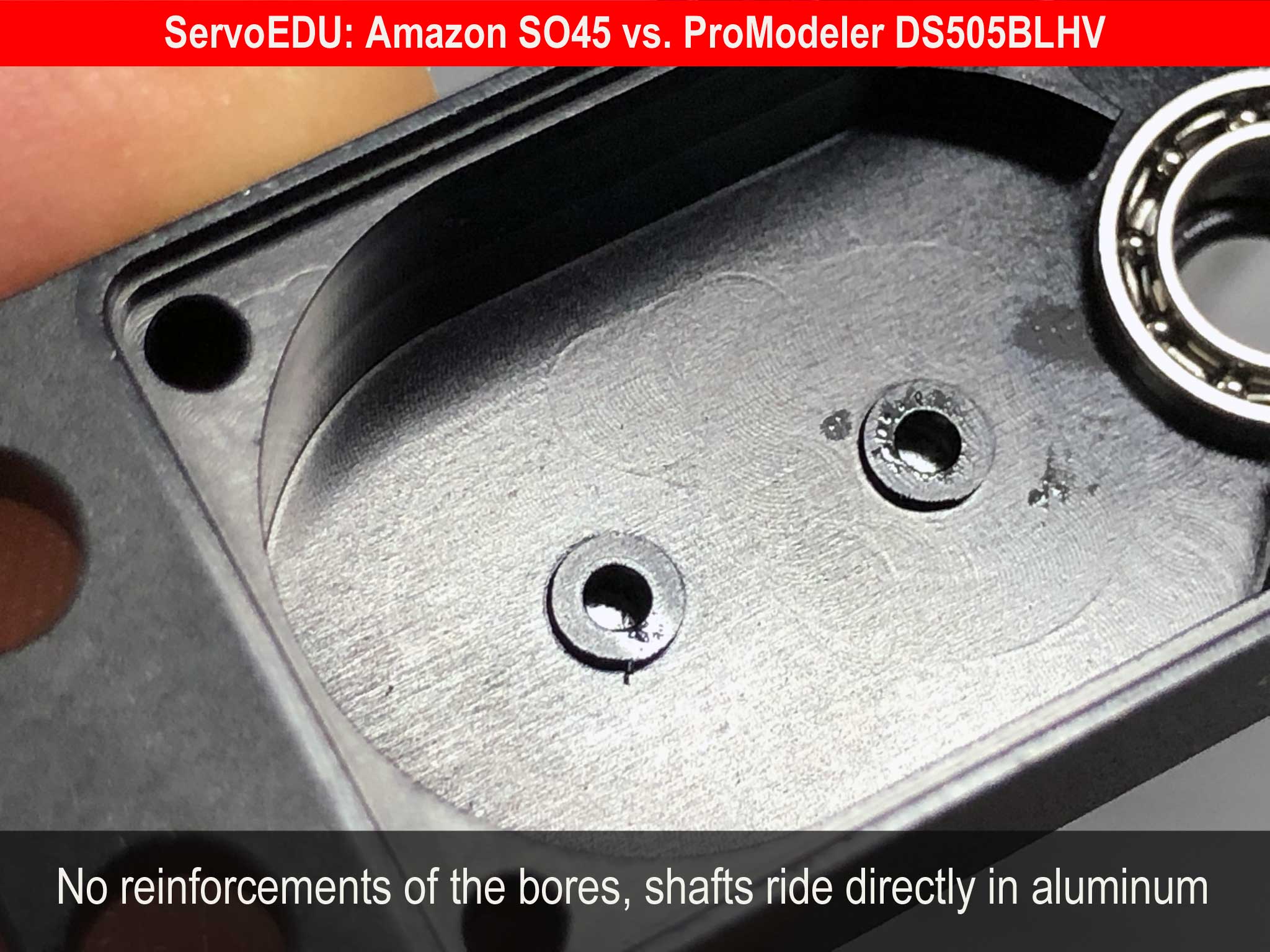

Question #5 - are you comfortable buying a servo where the bores aren't reinforced?

Answer 5: __________________________________________

My turn again. Look, from experience we know that because the hard steel gear shafts are of a relatively small diameter, that when fitted to bores within soft aluminum, they distort the bores very easily. This is precisely why we reinforced our cases!

The idea is to preclude this wear from happening early and easily. Anyway, these inserts are special. They're made on a machine called a Swiss lathe and they are very, very precise and quite pricey. Not only that, but they must be pressed in individually by hand, which takes time, and thus, is expensive. It's my opinion they left these out to save money. Our better competitors like MKS and Futaba? They use hard points like we do, also. Leaving these out is penny wise and pound foolish.

In summary, the basic reason we go to the trouble and expense of hardening the case is that without inserts, the steel shafts will - and in very short order - beat the case sections into submission.

By this meaning the perfectly round bores that support the shafts evenly around the circumference will go egg-shaped (meaning not round). And this happens quickly from just ordinary use, not even abuse, e.g. from running the rig around. Happens pretty quickly, too. Especially if you hit a hard object, e.g. like even the slightest bit of abuse will damage an aluminum bore.

Since the whole idea of a gear train is to keep the gears in proper mesh with each other (to deliver the smooth transfer of torque), then 'anything' that increases backlash (slop in the vernacular), is bad.

We (ProModeler) do everything we can do to reinforce the case to avoid excess wear. Leaving out the hardpoints relegates this servo to the bush leagues, in our opinion.

Honestly? This is a big deal and exactly what differentiates professional quality servos from consumer-grade. Is this alone worth the extra 40 bucks to you? Dunno, but it certainly is to me! And this is why I put my money where my mouth is and go to the trouble of reinforcing the case with hard points in the first place!

Bottom line? The instant the bores aren't round the entire gearbox is out of spec because the design gear mesh no longer exists. In a nutshell, it means accelerated gear wear begins. So cheap steel and poor support? Both?!?!

Please allow me to beat on this dead horse a little more. This is what you're getting. Steel shafts riding directly within soft aluminum. Bad!

- Brings to mind . . . penny-wise, pound-foolish

Anyway, as if they couldn't get worse, things are about to take a turn towards the bad news bears because we're breaking out the basic tools required for taking dimensions.

- Good tools taken care of - a lifetime investment

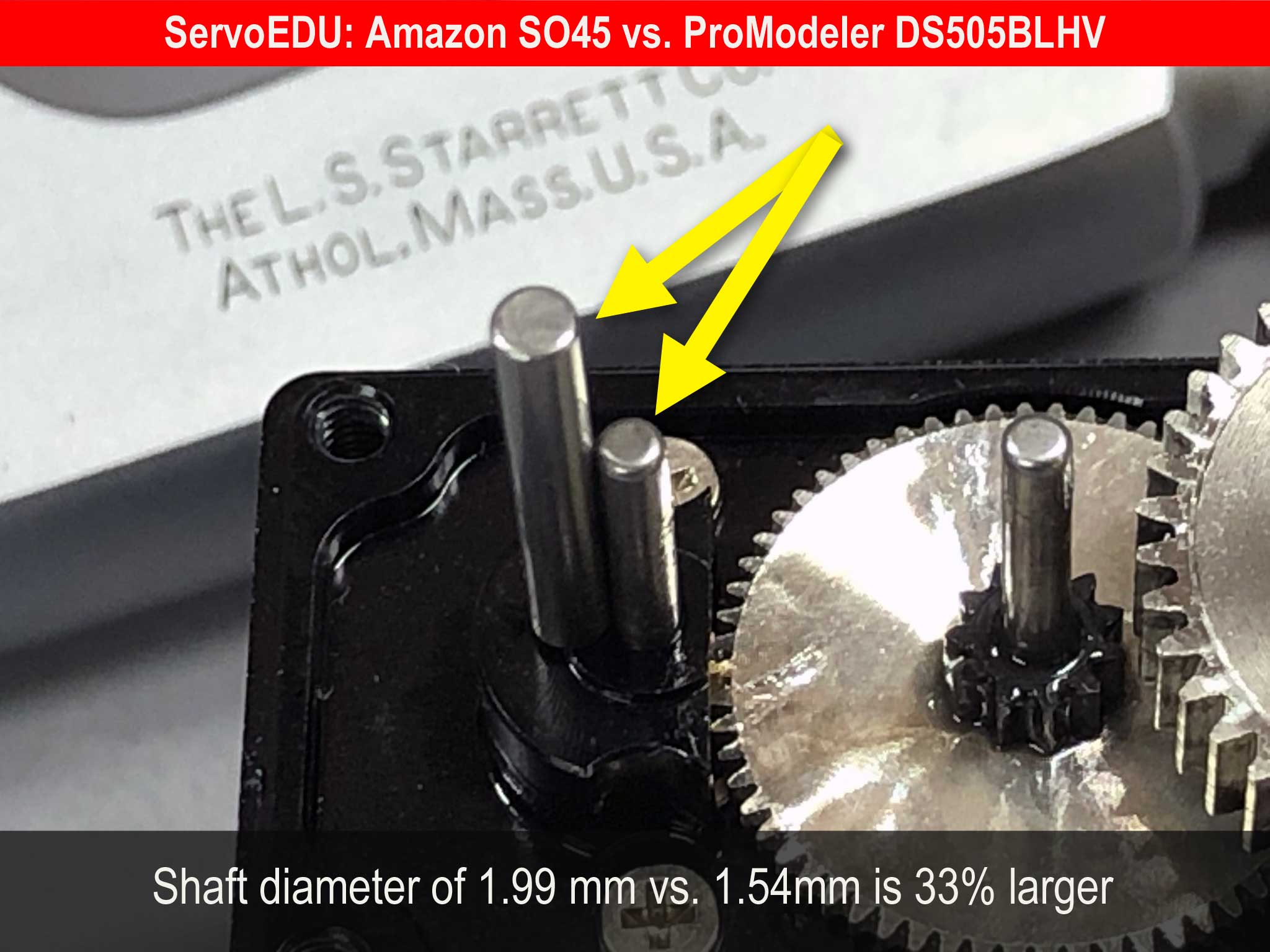

You can't overlook tools when it comes to taking the measure of a product (pun intended). This device is called a micrometer and this one has a pin in the anvil because I am going to measure the shafts the gears in the transmission ride on. Why? Simple, the bigger the better. Next question for you;

Question #6 - all things being equal, would you rather the gears ride on . . . larger or smaller shafts? Which do you believe will hold up better?

Answer 6: __________________________________________

I won't beat around the bush, you know the answer as well as I do. Here's an instance where you don't need to be an engineer to assess a larger shaft is stronger.

Basically a larger diameter translates into more durability, resistance to bending, as well as better at resisting fracture - all things otherwise known as failure. Want to avoid this, right? Anyway, eyeball this . . .

- Bit of grease holds the shaft in place for a photo

Honestly? Minimizing shaft diameter for what purpose? Yes, it affects the cost of the gears - but - for the power this thing can output, lightweight construction is short sighted in our view.

But what matters is . . . what's your opinion? Do you think smaller gear shafts makes sense for you, with a servo making this kind of torque? Strikes me as a pretty silly area to cut corners in our opinion, but there you have it.

Summary

So let's tie this all together and throw it on the scale. On one hand you have smaller diameter gear shafts, lacks hard points, smaller gears, poor quality steel, questions regarding spares and on the other hand, you save a few bucks. Hardly seems worth it to me, but it takes all types.

Now my question for you is . . . what type are you?

Low-buck only makes sense if it'll last. Meanwhile, I'm wondering this; for such a modest difference in cost, and with everything at risk, do people really buy expensive things without the bare minimum of research? Or is it they do not recognize the difference in quality when they buy these no-name products?

And here's another thing, remember this, these are the very same manufacturers making the label-engineered servos some folks buy from hobby dealers. The ones turned servo-brands by leveraging cheap imports. This, to try and get a piece of the pie from the unknowing, the easily influenced, and the stupid.

In short, what's the true cost of breaking your rig shortly after you go out because the servo couldn't take what you dish out? I'm not talking about the price of repair (none, because you have to buy another freaking servo because you can't send it in for repairs) but I'm talking about the cost to you for your time?

Time lost while your buddies are still having fun! There's a cost associated with buying cheap whether you recognize it, or not. So remember what Shakespeare wrote, 'to thine own self be true', so don't be lying to yourself about the relative importance of forty bucks, eh? Not when it's down to steering the rig. No steering? May as well be a doorstop!

Go look at the answers to the six questions. My bet is you'll find you actually 'can' put a couple twenties towards your sport by opting to run ProModeler servos. After all, we come well recommended for a reason, capisce?

I'll close with this; abh16 wrote in part . . . I don't buy a competition race-ready Porsche to drive around in New York city because it's overkill and I can't use its potential. Am I missing something?

For everything there is a time and a reason. I believe if you answer the questions posed honestly, then you'll see you actually 'have' been missing something. All it took was an insider to show you the importance of gear shaft diameter, the value of higher quality steel gears, how support is critical to durability so hardened cases bores with inserts are key, and all this before we get to the quality of their potentiometer, or the motor itself (and taking them at their word regarding the specs).

Closing

Wrapping this up, all you really need is a little bit of common sense and a set of eyes - this decision can be a no brainer.

For some folks the $60 Amazon special does the job, it's perfect for their needs. Valit decision. Offered the same choice, another guy goes, hmmm, with ProModeler I get . . .

- larger gears

- larger shafts

- better steel

- hardpoints

- cooling fins

- spare parts

- repair facility

- MIL-STD

- Someone to call

. . . and they wonder to themselves, all this for an extra $40? Oh Hell yeah! And this is another valid decision, for them!

Frankly, there's a place for both modelers on the spectrum of folks participating in our sport because there's always an element of learning. That, and everyone is at a different point on the journey of mastery and thus, as always . . . what's best for you? It depends!

What's next?

Unless your money grows on trees, it's my suspicion most serious modelers will judge the el cheapo servo doesn't pass the sniff test. So next question is this; if you can throw a few more bucks at the solution, what else does ProModeler have on tap? How about a Series II servo, like the DS845BLHV or even DS1155BLHV?

Note; the Savox in this photo sports gears similar in layout and size to those of the DS505, but the DS635/845/1155 Series II servos turns the volume up to 11. And in case you aren't aware, ProModeler go to 2685oz-in if you want to play in the big leagues!

Last thing, if you have any further questions, reach out to me via email:

- or if it's urgent, call; 407-302-3361

. . . because I love bullshitting about models more than anything!