What's this servo for? Smooth and powerful, the water resistant DS360DLHV is a high voltage (HV) digital servo built on a tough hybrid case, which is crafted of aluminum and engineering polymer (plastic). Equipped with cooling fins for near continuous use, the center-section is CNC-milled from a solid billet of 6061-T6 aircraft aluminum. Meanwhile, the electronics cover (bottom) and the transmission section (top) are injection molded of impact resistant fiber-filled Nylon 6,6 (like what's used for a Smith & Wesson handgun frame).

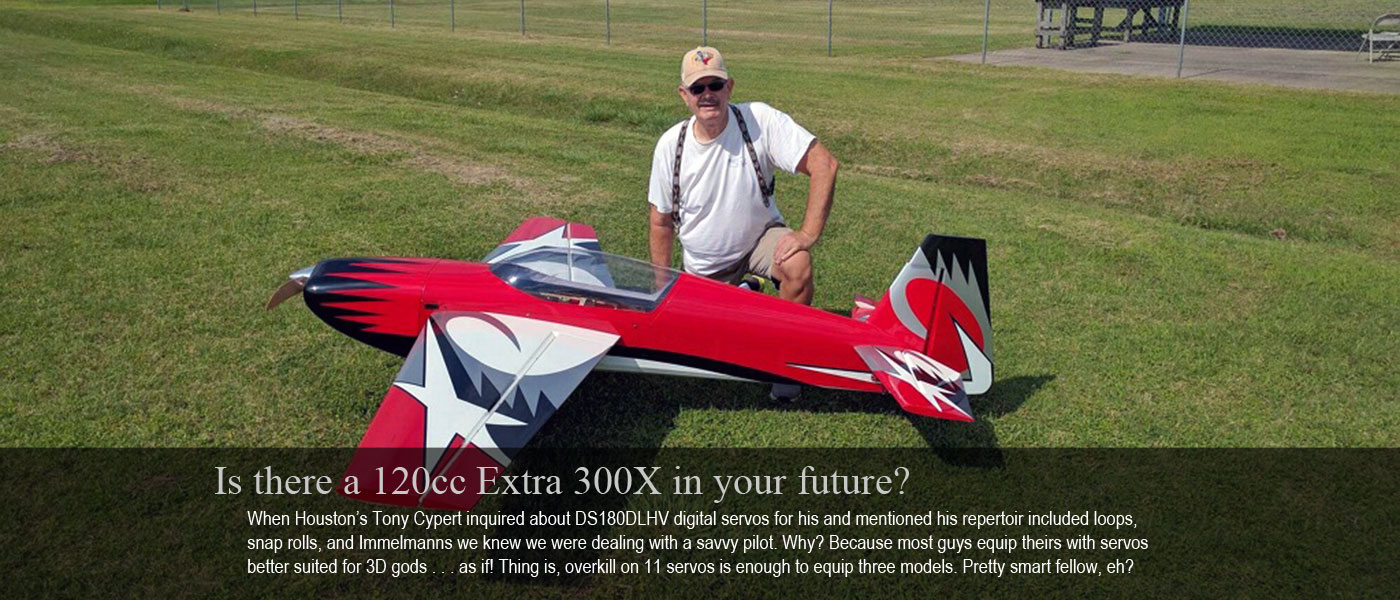

What's more, the upper is reinforced with bronze hardpoints where the steel gear shaft fit into their pockets for maximum durability. Secured together with 10 Allen-head bolts instead of four Phillips head screws, and equipped with dual ball bearings plus all-metal gears (for strength compared to plastic gears), it outputs 360 oz-in of torque, or well over 20 pounds of force! With a transit time of just 0.14sec/60°, this is what's called a standard-size servo - meaning it fits most sport use remote control airplanes

We've grouped the information you need into various tabs. For example;

- Specs - useful if you're curious about the raw numbers, dimensions, etc.

- Comparison - will help guide you regarding specific product differences.

- TL;DR - gets down into the weeds with the nitty gritty - it's for the detail-oriented.

- Reviews - short and sweet with real names and places - no BS.

INTRODUCTION:

Part of what makes the ProModeler DS360DLHV better than competitors is that unlike hobby-grade

servos, it's built to meet military standards (and subjected to these tests).

MIL-STD-810G-Part 16

- Shock - Test Method 516.6

- Vibration - Test Method 514.6

- Rain - Test Method 514.5

In part, this is due to the requirements of our primary customer. However, because we're modelers and have knocked a servo off a workbench, experienced crashes, and know a thing or two about engine vibration. it's built with 13 o-rings because like you, we know how a summer afternoon pop-up

rain shower may drench a model before landing, or flying off water with a float plane. It's why these tests are important for civilian users, also!

Ownership Considerations:

Serious modelers - whether they're flying smooth aerobatic maneuvers, or a scale warbird - often opt for ProModeler servos

because of superior centering performance. In part this results from our using MIL-SPEC components, but it's also due to our using a genuine Japanese Nobel-brand

potentiometer versus a cheapo clone, or maybe an inductive pickup (Hall sensor), or some other cost-saving measure.

The DS360DLHV servo is perfect for model airplanes ranging in size from .40 through 80cc giant scale model aircraft. Equipped with an all-metal gear train, it's a smooth and strong performer but not recommended for 3D models where engine vibration combined with huge control surfaces will wear them out in short order, or for surface use where more costly but more shock resistant steel gear trains comes into their own (this is especially true for 3D aircraft, too). Expressly crafted to meet your needs whether you're a beginner looking for your first set of high quality servos, a highly experienced sportsmen attending several events or fun flies each summer, or an all out pro equipping a competition scale aircraft!

DETAILS:

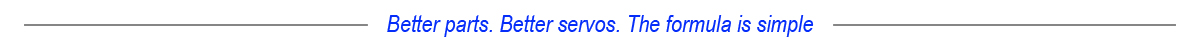

If

you're an electrical engineer you'll immediately notice we protect the PCB

from vibration with a conformal

coating instead of a little square of foam rubber. Referred to as

potting compound on the civilian side, we call it monkey-snot because

it's such a sticky mess to apply. This stuff is applied to the PCB and

oozes between components and once it sets is what lets our servos thrive

in harsh high-vibration environments. This is an aerospace-grade

technique and it makes ProModeler servos more valuable.

Another

area where a ProModeler servos stand out is protection from

environmental contaminants, typically dust,

water, and exhaust-oil. The assembly of the DS360DLHV is protected with

o-rings - basically at every opening - even beneath the screw heads! We

all know how pernicious water can be with respect to penetrating where

we don't want it so that this makes ProModeler servos better than servos

without this level of protection is a no brainer.

As you learn how well the DS360DLHV servo is made you might reasonably expect this to

be our most expensive servo, but it's not. Instead, this is our best

general purpose servo. It's the servo that expert modelers select for a

wide variety of sport and scale model airplanes.

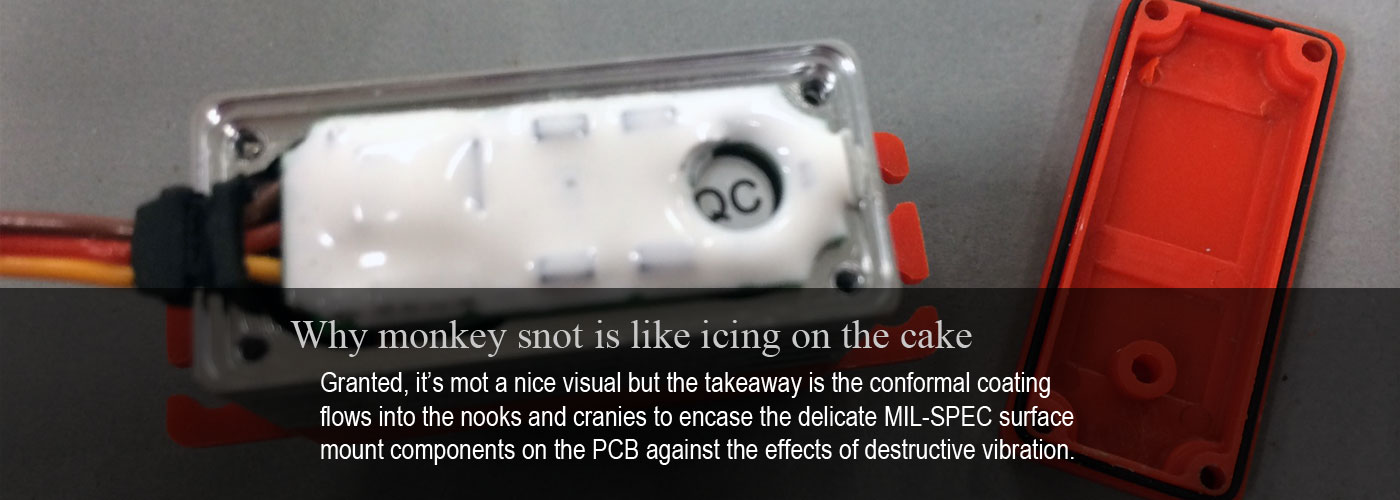

For example, savvy pilots, especially ones who grok what

Eastwood meant (in the role of Callahan in Magnum Force) when he said,

"A man's got

to know his limitations."

- will opt to use these for models as

large as a 120cc gasser. Especially when using several to drive the control surfaces for sport use. This last sentence is important because if you're a 3D maven then you're wise to be looking elsewhere in our lineup for faster, more powerful options. Servos like the DS255BLHV for models through 78", DS415BLHV for for models through 82" models, DS635BLHV for 85-91" models, or DS845BLHV for 33% models, or even our top of the range 1155BLHV for 40% models.

Meanhwhile, if you're into old-school aerobatic - gentlemen maneuvers like loops, point-rolls, stall turns, as well as occasional snap maneuvers and Lomcovák - then you may be tempted thinking you don't need super fast and powerful servos. Thing is, times have changed and the sheer size of the new type control surfaces are too much for this type of servo construction so you may think this is the perfect servo for you. Major point of disclosing all this is to whet your appetite but also temper your expectations, because this is a lovely servo - but - it's our entry level, so if you put it to heavy duty use, you'll be disappointed because it's not made to be used like our more heavy duty products, capisce?

- With 2 on each aileron, elevator, and rudder, even throttle, DS360 worked well for a scale model as large as this - but not for 3D

Ever taken a servo apart? The metal gears rotate on steel shafts. The end of the shaft fits in a hole in the case, what's called a bore, or a pocket. Within el cheapo servos, the steel fits into a plastic pocket but in a ProModeler servo, there's a brass insert reinforcing the plastic - a hardpoint. While you pay a little bit more for a ProModeler servo, this is part of the reason why. As long as it moves, we know modelers won't throw anything away . . . so we produce ProModeler servos with the expectation of a service life measured in decades!

USE CASES:

So

who

uses these servos? In light of the MIL-SPEC and MIL-STANDARD test

methods, you won't

be surprised to learn the government has driven a lot of our product

development. They're our important customer. So are universities, plus

commercial UAS operators performing agricultural and pipeline inspection ops.

And because we've branched out to the civilian world, our customers now include

hobbyists.

FAQ

Q. I have a 104" Extra with a DA120, is this enough servo? All my buddies say I need to buy ones that cost as much as $140-220 each. Will these $50 servos work well for the flight controls and throttle?

A. Maybe. Depends how you fly. But honestly? Your buddies are probably giving you good advice. Surprised I'd agree with them? Maybe if you flew it like a grannie they'd be OK. For example; a club pilot, or someone who flies the smooth schedule of IMAC type maneuvers, then yes, the DS360DLHV are a decent choice, especially because this kind of model uses multiple servos for ailerons (so two servos are outputting a combined 720oz-in, which is plenty of power). Dditto dual servos on rudder. Overkill, yes, for throttle where our DS255BLHV is probably a better choice because it's faster and has all-steel gears but yes, you could use DS360 all the way around and be quite happy. But I still wouldn't advise it. Why not?

Simple, it's because pilots flying 3D airplanes want to also fly hard maneuvers (think rifle roll where a very large aileron is stuck into the breeze at 80-100mph). The critical part of this is huge control surfaces, means lots of force. Added to the long servos arms providing leverage it means accelerated wear. Speaking of wear, gassers making loads of vibrations - most especially poorly balanced single-cylinder engines resembling a paint shaker - and it's not a good combination for the metal in gear trains that are not also, all-steel (more money, of course).

Honestly? Most especially pilots into performing rapid reversal maneuvers at high speed like Rifle Rolls, or who like the 'oooh' from the crowd when they hit the Wall midfield with an abrupt pull or push following a full dive into a high speed pass, then no, these servos are absolutely NOT the best choice. Not to put too fine a point on it but they're not fast enough, nor durable enough to hold up for that kind of duty in a 3D model

. Not a bad servo but not our best, either. So the answer is 'yes, but, or maybe' because it depends not just on how you fly, but what you fly. It's a sport servo made for sport models (and warbirds with comparatively small control surfaces). Yes, we want your business - but - not enough to lie about it.

- Note 1; if you could be fairly described as a club or IMAC maneuver pilot and appreciate the finer things in life, we believe you'd love the DS415BLHV instead because it's much faster and has all-steel gears but with really large models, especially due to the how newer design models have very large control surfaces, then we'd guide you to our DS635BLHV for a 120cc model if not more powerful, instead. Why? For the oversize all-steel gear train. Anyway, if you actually fly the contest circuit and practice 3-5X a week then the benefits of a brushless servo also pay off in spades, anyway.

- Note 2; if you routinely perform rifle rolls and walls at high speed, the appropriate servo is the DS635BLHV, DS845BLHV, or DS1155BLH2.

Q. I'm building a 120" Super Cub and powering it with a BME100, I'd like to use a DS360 on all the flight controls and a DS130 on throttle. Thoughts?

A. Good choice. Exactly what I'd select for this model if I were building one. You haven't mentioned it but because 360oz-in is a bit of overkill, you can sacrifice a bit of that power by using a 6.6V A123 battery pack. This versus the 7.4V of a LiPo because you can charge LiFePO4 packs in the model (never charge LiPos in your model because of the fire risk). Anyway, I'd choose between the B2S2500 or the B2S2P5000 based on how long I intend to fly during an outing. Cubs are superb for summer days shooting touch and goes until the sun goes down, and for passing the transmitter around your pals so if it were me I'd probably lean toward the larger receiver pack.

Q. Will a DS360 work well for steering a Traxxas TRX4 or a 1/8th buggy?

A. Maybe. The DS360 has the power and speed but in our opinion, not the toughness. It may work a while, but you're probably going to break it eventually. We know because while the servo is rated to 360oz-in and the gears are good to about 420oz-in, we nevertheless sell a fair number of replacement gear sets to surface use owners - there's a reason. Moreover, after a set or two they eventually wise up and follow our recommendation to upgrade to a more heavy duty servo - or - get POed and buy another brand. Of course we're sad to see them go (nobody is in business to tick off their customers) but the simple fact is if you've never seen what surface vehicles undergo in slow motion you'd be amazed the servo last for even one battery pack! https://www.youtube.com/watch?...

Anyway, while we'll put our $50 servo against anybody else $50 servo in terms of quality and build - in all honestly - our recommendation for surface use is you're better off with one of our steel gear servos like DS255BLHV, DS415BLHV, DS505BLHV, DS630BLHV, DS635BLHV, DS845BLHV, DS930BLHV, or DS1155BLHV servos instead. And being more costly products, they also have better quality brushless motors. Don't know diddly about servo motors? You're not alone, review this article where w explain what makes each motor type different. About RC servo motors. And no worries, clicking the link opens in a new tab so you don't lose your place.

Look, we're straight up with you because we want you to be happy and while the DS360DLHV is a great servo, its duty cycle and gear train strength just aren't really compatible with real life surface-vehicle use. Will it fit a buggy, basher, or crawler? Sure, but it's just not built for that kind of use, it won't hold up. Pick something else instead. Remember there's a difference between theory and practice and in theory a DS360 is OK for surface use but in practice it's not advisable.

Q. I know the DS360DLHV is overkill for my Sig Kadet (a glow-powered 40-size trainer - editor) but I'm already thinking of building a Hangar 9 30cc Ultra Stick so I want to use them in this model next.

A. Good thinking. Very few beginners are savvy enough to think ahead to their next model. You're showing wisdom beyond your level of experience. Speaking of experience, with it you learn your interests change over time. That, and the ideal servos for a 62" wingspan model - for what amounts to lunch money - can be upgraded to ones suitable for a much larger mode because they're the exact same size, which in the business, is called standard size. Anyway, this is the best future proofing you can make of your servo investment - well done!

Q. I want to use a DS360 in a Traxxas Bandit (2WD buggy - editor).

A. This is a decent choice for bashing in the yard but you run the risk of tearing up the gears and breaking the plastic case. Honestly, for surface use a better choice will be equipped with steel gears and an all-alloy case. Look to our DS255BLHV if you're OK with a hybrid case servo, or an all-alloy brushless series DS505/630/635/845/930/1155BLHV. especially because once you get competitive you'll prefer the faster lock-to-lock of these higher performance servos (allowing you to more readily out turn a competitor). And the latter especially, for the toughness of steel gears and an all-metal case.

Anyway, you may use this servo in a wide array of sport and scale models, with wingspans ranging from about 48" on up. And when we say 'on up', we're not kidding because the models in which the DS360DLHV may appear can be as spectacular as scale model of a J-3 Cup spanning 140".

SUMMARY:

At

heart, servos offering 360oz-in of torque and transiting in the

0.14sec/60° range are available from other vendors. We know that. But we also believe finding another servo that

offers everything this one does is impossible. To the point we believe there isn't a better servo - for the money - on the planet.

Period. No other servo offers

this level of power, precision, quality, plus tank-like toughness (and nobody else lets you completely

rebuild them yourself).

Better

components. Better servos. The formula is simple. Decisions regarding

what goes into ProModeler servos aren't made in accounting to optimize

price and profit, but in engineering. This servo isn't sold for $40

because it costs more than that to make, but in light of what goes into

it - at $50 it's a pretty darned good value. Simply put, this is the best

servo available for the money. Add a set to your cart. Do it now because you're

going to love them!

Other Resources

For detailed specifications and dimension drawings, select the Specs tab above. Also, there's an even-handed look at the competition in the Comparison tab. Meanwhile, TL;DR

is chock full of nitty-gritty details - where we disassemble and show

you this servo side-by-side with a popular competitor. If you love

delving deeply

into stuff some find too tedious to read, don't overlook this tab.

Note:

operating voltage is 4.8-8.4V, but optimal performance is obtained with

a 2S LiPo instead of a BEC. This is because LiPos deliver the required

current without voltage spikes, noise, or otherwise adversely affecting

the delicate avionics (25C or better is recommended). After all,

synthetic orange colored Tang may have gone to the moon, but it doesn't

compare to freshly squeezed orange juice. Same thing when it comes to

feeding your avionics!

Seeking to make a great servo for sport pilots, we created the

DS360DLHV by using the case-design of our top-of-the-range DS305CLHV coreless motor servo, and matching it to a super-reliable 3-pole iron-core motor. The end result is precise and powerful - with all the nice bits of speedy coreless motor servos - minus the pricey motor. If you're a sport pilot (versus 3D where 90° throw in the blink of an eye is required), this servo strikes a perfect balance between price and performance.

Engineered-polymer upper and lower case with brass inserts - the DS360DLHV foundation, the center case, is CNC-machined from a solid billet of 6061-T6 aircraft aluminum. Like a radiator, it keeps the powerful HV-motor nice and cool. To save weight we use fiber-filled Nylon 6,6 (an engineering-polymer like that used in a Glock handgun) because it's strong and impact resistant. And to ensure it's durable, we use brass inserts in the pockets for the steel gear-shafts.

- Bronze inserts where the steel gear shafts ride in the polymer upper-case ensure long lasting precision gear-mesh.

Gear train - all metal gears makes this servo strong. The 25-spline (Ø5.96mm) output shaft is Futaba compatible for convenience. Material selection makes it tough. Exotic titanium-ceramic (TiCN) armoring of the 7075-T6 output gear (same aluminum-alloy used in components of the upper receiver of an M-16 rifle) means this massive gear has an 800% increase in wearing surface hardness. Combination-gears mate C86300 manganese-bronze with 4140 chrome-moly steel for optimum strength and wear characteristics.

- TiCN/7075-T6 output gear, plus bronze/4140 chrome-moly steel combo-gears perfectly match durability with strength.

O-rings - have you noticed how some really expensive servos don't have o-rings? The claim is electric models make them superfluous. Since getting caught in a pop-up rain shower isn't unheard of, and re-purposing servos into a nitro-powered model a year later happens all the time . . . do you buy that line of reasoning? We figure it's because the manufacturer pockets a few extra bucks but leaving o-rings out comes at your expense. Is keeping water, fuel, and exhaust residue out of your servo important to you? Wanna know why the S160DLHV is fully o-ringed? Simply because our engineers make these decisions - not our accountant!

- Now you see them, now you don't . . . fully captured hidden o-rings make the case resistant to water, fuel, and oil.

Nitty gritty - it's said the measure of a man is what he does when nobody is looking - take our servo's measure the same way. Ever disassemble a servo? They typically use four long-ass Phillips head screws, which come up from the bottom, sandwich the center section, and actually thread into the plastic top-case, right? However, an S160DLHV is built better. How? To begin, we use grade 12.9 Allen-head machine-thread bolts instead of el cheapo screws. Six come in from the top plus four more from the bottom, and instead of sandwiching the center case, the ten bolts actually thread into the aluminum. The result is a far more rigid assembly that's so much better . . . it's not even fair to compare!

- Note how an S160DLHV servo is assembled with Allen-head machine-bolts vs. el cheapo Phillips-head screws!

Packaging - nestled within a high density foam insert for protection, each S160DLHV servo arrives packed in a jewel case. Since good looks never hurt, we use red polymer to show off our brand and laser-etched our logo into the polished aluminum center-case. These servos look great - think in terms of the fit and finish equal to, or better than, servos selling for more than $200. Bottom line? For the craftsmen who appreciates our high standards because we pay attention to the smallest detail, we hope you'll be as proud to install them in your model as we are to make them.

- We proudly brand our product with the ProModeler logo . . . and hope you'll be as proud of them as we are.

Better components.

Better servos. The formula is simple.

Most of us have felt that lurch of panic as we dropped a servo during installation and snatched it off the floor to inspect for damage. It's this shared experience as modelers, which led us to build the DL-family of servos to an aerospace-standard.

For example, to better mitigate against shock (and vibration), we use what the military refer to as a conformal coating to protect the delicate electronics components mounted on the PCB (printed circuit board), Compared to the square of foam rubber used in hobby-grade servos, we call the white stuff smeared over the electronic components monkey snot because it's such a sticky mess to deal with during application. Which do you think is better?

Anti-vibration and impact protection are a big deal to our military

customers. Perhaps you aren't flying a million dollar UAV, but if you simply want

better servos for your pride and joy, monkey snot is one reason they

rely on ProModeler servos.

Also important is how we use MIL-SPEC components - plus the best motors and potentiometer money can buy. These are critical for the best centering performance possible. Yet nothing is quite so telling as this simple fact . . . you can actually buy these components from us. While hobby-grade servos offer cases and gears, serious pilots appreciate being able to go a step further without returning them for service.

Granted, sport pilots probably don't fly enough to wear them out in a decade but competition pilots - ones who get in 4-5 practice-flights 3X during the week (plus the same, or more, on weekends) can wear them out inside a year. If your winter-project list includes returning your servos for R&R, but you can make three solder joints as well as the factory technician, then you can save money. Why? It's because we know DIY is a big part of the hobby. If you appreciate being able to bring your servos back up to snuff without breaking the bank, then ProModeler servos are probably better for you, also.

Restoring like-new performance with a simple job like replacing a potentiometer (with three easy to solder joints) while forcing you to return them for service only to charge 'almost, but not quite enough' to make it uneconomical isn't what ProModeler is about.

Restoring like-new performance with a simple job like replacing a potentiometer (with three easy to solder joints) while forcing you to return them for service only to charge 'almost, but not quite enough' to make it uneconomical isn't what ProModeler is about.

Meanwhile, do you believe in better engineering? We do too. Unfortunately, unless you open it up to look after buying, the other guys don't make it very easy to know what you're actually getting. If you appreciate attention to detail, yet another thoughtful touch (one that ensure your investment in these servos delivers value) are the bronze bushings reinforcing the gear shaft pockets.

To recap, not only is the molding for the polymer pocket more robust on our case, but the bronze inserts reinforcements are there so your servos will last, and last, and last! Bottom line? Understanding the difference between something's price and its value comes down to grokking the details.

Along the same lines, a big difference for why experienced modelers prefer ProModeler servos and something priced about the same is found in how the center section is made. One the one had an injection molded piece, on the other one that's better because it's made of aluminum so the motor cools better when you're working the servos hard, has cooling fins for shedding heat more quickly, and is drilled and tapped to accept fine thread machine-screws for the ultimate in rigidity.

Finally, eyeball all the major components laid out side-by-side. We suspect it's rather easy to see why your next set of servos should be from ProModeler. If you're especially sharp eyed you'll have noted the assembly uses 10 Allen-head bolts with machine-threads instead of 4 Phillips head screws with cheese-cutter threads. You'll see how each has an O-ring - and - threads into aluminum instead of plastic. You also also know to look out for gears represented as metal but which include a plastic gear so fragile they sell replacements in 3-packs. You also understand that servo manufacturers that shove a cheap piece of foam beneath the electronics cover and call it good aren't just shortchanging you, but playing roulette with your model by paying less than perfect attention to vibration protection.

As you get a better idea of what to look for, you buy smarter. It's as

simple as discerning the differences between hobby-grade and

professional-grade.

So let's tie it all together. Better parts. Better servos. The formula is simple. It's a no-brainer and paying the same, or more, for another brand just because it's what others do is a non-starter with savvy modelers. You've found the servos you want for your next model.