I occasionally field questions regarding servo connectors and extensions. Let's briefly delve into some mechanical and electrical considerations because basically, we (all brands) play by similar rules. It's physics - not opinion.

Connector: Mechanical

Pin spacing - even though we all use 0.10" spacing, some manufacturers try to lock users into their brand. The Futaba blade sticking up is an example that comes to mind. Modelers have been slicing 'that' little bugger of since inception because you're just not locking the door on inventive modelers who 'will' find a way no matter what. ProModeler servos and accessories come with a universal connector because we figure you're with us by choice and if you want to leave, we're not standing in your way!

Basically, within the electronic world at large the 0.10" pin spacing is common as dirt - everybody uses it! So anything that makes it harder to use is boils down to making it harder on customers for reason of making more money off them and I don't agree with the practice.

Note 2; the pin spacing on these things is 0.10", a read as 1/10th of an inch. Sometimes you'll see 0.10" listed as 2.54mm, which is the same thing. Point being, this is not some RC modeling-derived standard. Instead, it's an example of modeling adopting something already in far wider use within the world of electronics.

For example, if you've ever been inside a computer you've seen headers with 0.10" spacing (and matching connectors). Where? On ribbon cables! Like for peripherals where they've been used to connect disk drive units and floppy drives plus all sorts of serial and parallel connections. Even cables with USB and HDMI on one end connect to the motherboard through this type of pins on a header. And they're used in industry for control electronics for CNC machines and robotics, too.

Connector & cables: Electrical

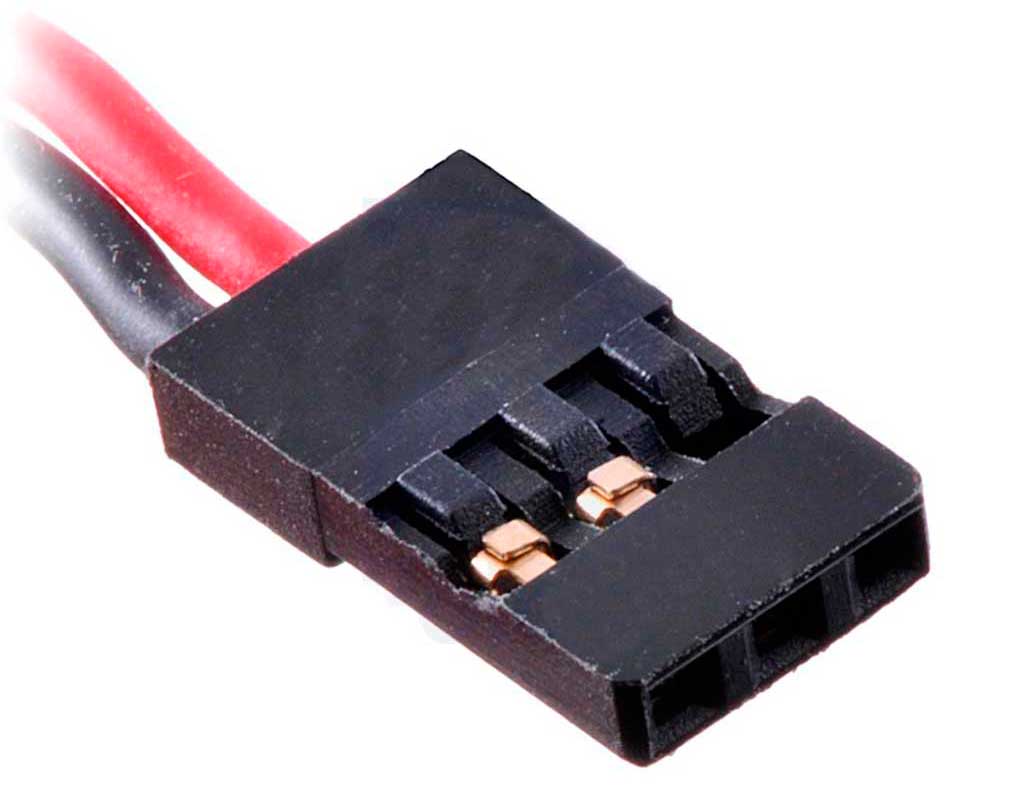

Current handling - the pins are good for 3.5A continuous (5A intermittent) and are arranged by color in this order: brown/orange/yellow (or black/red/white). This is important because even if you manage to insert it the wrong way around, nothing bad will happen and you never make a circuit as when reversed, so while positive still goes to positive,and vice versa. Thus, the circuit between negative and positive will never close meaning nothing happens. Note; brown/orange (black/red) correspond to negative (-) and positive (+) to a battery (DC), respectively. The yellow (white) is the signal wire.

Gauge - the rule of thumb for gauge (size) is the smaller the number, the thicker the wire, and thicker wire handles more current. Both 24GA and 26GA leads are fairly common in the servo world. Heavy duty servos tend to come with 22AWG leads - meaning better suited to consuming more current. It's similar with all manufacturers.

Testing the limits

On the high end of current demand is the 20AWG lead. Honestly, if I were king for a day I'd switch to a connector that would live with 18-gauge (or 18AWG) wire but this is impossible with the DuPont which won't accept thicker than 20AWG. But that would mean changing the entire servo-world from the ubiquitous 0.10" spacing DuPont servo connector. In short, we deem it is basically impossible to get all modelers to ditch their receivers and other control avionic infrastructure and make an update. So we deal with the limitations and come up with workarounds.

Since everybody won't ever get together, one good rule of thumb is to always go down in gauge when you use an extension. If you've got a servo with 28AWG leads, go to 24AWG, 22AWG, or 20AWG leads for the extensions. Thicker is better in terms of current flow. All ProModeler standard size servos use 22AWG so we offer 20AWG extensions on the site.

Note 3; 20AWG is the thickest wire you can commercially crimp within DuPont connectors.

All that said, in the world of standard size servos, some servos approach the current handling limits. This is why for some of our servos we've gone to a separate set of leads, one for control plus a supply lead carrying power separately to feed the high current motor. These have;

- A standard 22AWG 3-wire Dupont connector to the receiver, and

- A separate 18AWG lead sporting the ubiquitous XT30 for power

So ProModeler - instead of trying to force the world to use another connector - split the control and propulsion power into two leads to the special servos. But I digress.

So how much current are we talking about handling?

- 24GA - 3.6A

- 22GA - 5.8A

- 20GA - 7.9A

This is more than the connector as you want the replaceable connector to fail before the wire. Naturally, thicker wire is also a little heavier. We've heard modelers who should know better say they're using lighter weight extensions to save a bit of weight. They're right but wrong footing the issue, in our opinion. Experienced modelers grok these few grams are chicken feed in the grand scheme of things.

After all, if the wire isn't capable of handling the current loads without overheating or greatly reducing voltage in the process, what's the point of having powerful servos if you're going to throttle them from full output by giving them inadequate current? May as well piss your money away as shortchange the servo's power requirements! Bottom line? For high power demands, thicker leads are better!

Note 4; the signal-wire thickness is usually not a factor because it doesn't carry significant current but it's typically the same gauge as the two leads powering the servo because it's easier to make extension leads this way.

Another thing; none of this applies to light model builds where 100oz-in and 1.1A are high current consumers. In this world 28 and 32AWG are legitimate gauges. Using 20AWG extensions with low current overall is pointless. So the discussion of 20AWG for extensions is related to standard size servo loads and high current draw, OK?

Voltage - all ProModeler servos are HV (high voltage) capable. Yes, they'll operate down to 5V (4.8V nominal) and we share the specs for those interested in low voltage operations, but even a casual reading of the specs shows performance decreases as voltage drops. Since high voltage servos are all about performance, why not get all the performance you've paid for?

Extensions

Rules of thumb - extensions should never be a lesser gauge than the servo lead. Any time they're more than a foot long (~30cm), we recommend increasing to the next heavier gauge. And while we've heard some modelers claim to use 18AWG wire into a servo connector (possibly by shaving down the insulation and taking special care with crimping the strands of wire), commercially, 20GA (20AWG) is realistically about as thick as you can get.

This is due to the need for manufacturing using industry standard crimped connectors fitted to the universal plastic connectors. Reason we don't offer extensions longer than 52" (~1.4m) is related to voltage drop. How do you calculate this voltage drop? It just takes a bit of grade school math and one well known formula.

Voltage Drop

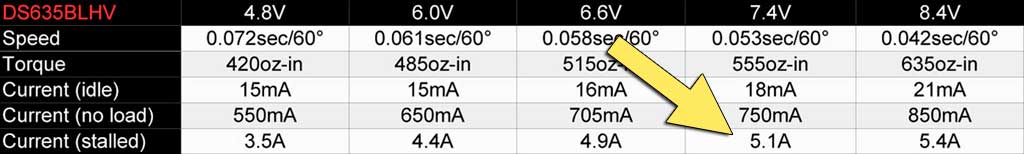

Example 1 - let's say you want to connect a couple of DS635BLHV servos on the elevator of your 85" Extra - one for each half. You want to know the worst case scenario for how much torque you'll really get from the servo using 7.4V (a 2S LiIon pack). This, to see if it's really going be enough to handle anything you may throw at it.

Visit the specs tab of the DS65BLHV to see the stall current. Go to the voltage column and go down to the 5th line, which is current (stalled). This is the worst case scenario.

Stalled current demand is a whopping 5.1A (at 7.4V). So if you determine you're going to need a 4' extension to reach the tail of your model (a 48" extension is very common for a 33% model airplane with servos mounted at the stabs) then since we recommend using no less than 20GA once extensions let's see what the voltage drop is.

We need to know the resistance of 20GA wire for our calculation. Consulting the chart for 20AWG wire (AWG is American Wire Gauge), resistance is about 10.15Ohms/1,000 feet or 10.15/1000=0.01015Ohm/foot.

So how much voltage drop will a DS635BLHV experience at full stall, e.g. the worst case scenario? First, remember the 4' extension is actually 8' of wire because to complete the circuit we're dealing with 4' of (+) side, the orange conductor plus another 4' of (-) side, the brown conductor, OK?

Now let's turn to Ohm's Law and figure this out. You'll recall from high school physics E=IR (Voltage = Current x Resistance) so let's plug in some numbers and see what we have . . .

- 5.1A x 0.01015Ohm/foot x 8feet = 0.41412V (let's round it down to 0.4 or ~1/2V)

. . . this means that using a 4' extension of 20GA wire, when the servo is at full stall you've essentially lost from 7.4V to 6.9V This is a lot!

Surprised? You shouldn't be. Fact. And from this you should extrapolate it's basically impossible to get full rated torque and speed using 'any' extension, which makes a good case for mounting servos near the CG, but that's a subject of another article. There's a workaround. We'll get to it.

Example 2 - what if instead of 20AWG extensions you followed the advice of the loudest voice at your club field, the guy who says he's been using standard hobby shop grade 24GA extensions for years? Same math and for 24GA wire the loss is 25.67Ohm/1000' or 0.02567/foot, you just plug that in and you get . . .

- 5.1A x 0.02567Ohm/foot x 8feet = 1.02V (I'd round it to 1V of loss)

. . . and this works out to 7.4V-1V=6.4V at the servo. Looking at the servo spec again you'll see it'll be outputting 485oz-in, which is a far cry form the spec at full rated voltage. So much for the guy with the loudest voice, eh?

Granted, the loudest voice at the club field probably has been operating just fine with 24AWG extensions but this is because he's been flying 200oz-in servos not 600+oz-in!

That, or he's all-mouth instead of all-pilot (meaning he's not the guy stressing the model enough in the air to notice the difference). However, there are pilots easily capable of noticing a 1V loss at the servo. This serves as an example of how you had better do a little bit of math instead of assuming. So with powerful servos, 24AWG won't cut it. 20AWG is already too much loss.

Example 3 - using a 20AWG Y-connector to drive two servos from one channel. This is bad on more than one level.

First, it doubles the voltage loss. Thus, using the values from example 1, instead of a loss of 1V it would be a loss of 2V, meaning instead of the servos getting 7.4V they'd be seeing 5.4V (or about 900oz-in). But that's with a LiIon pack, what if you're using a LiFePO4 pack instead of a LiPo? Now nominal voltage of 6.6V instead of 7.4V meaning the servos see 4.8V so torque is down to 430oz-in . . . Houston, we have a problem!

But it gets worse because there's another, possibly bigger issue at hand. And this is because the practical limit for 20GA wire is 7.9A. Thus, while you may think you're only stalling at 6.6A, the real world is worse because there's resistance in the connectors and the resistance is calculated at 60°F degrees. What if we do the math for 120°F, like the inside of your model on a hot summer day? Things get worse.

Bottom line, our advice is don't use Y-connectors with big hairy servos because it's bad juju (but do the math first instead of crying later). And don't use any less than 20AWG extensions and keep them as short as possible!

Work around - if you're ever going to make a long run to the back of a model (or way out in a wing panel), a lot of highly experienced modelers will snip the wire lead off about an inch beyond the servo case. Yes, this voids the servo warranty. Oh well. So next then they'll solder 18AWG wire directly to the brown and orange power leads (leaving the connector going to an extension comprising of just the signal lead - one lone wire of 20AWG (or even 32AWG, doesn't matter for signal). But no connector for power, they jump to thicker 18AWG wire which has a loss of 6.385Ohms per 1000'.

- 5.1A x 0.006385Ohm/foot x 8feet = 0.2605V (let's round it down to 0.25 or 1/4V)

Don't know it but there's a big difference between 1/2 volt and 1/4 of a volt of loss. There's going to be some no matter what. Going to 16AWG wire takes you to 0.21 or 1/5th a volt of loss. Anyway, the math works out to substitute 18AWGand maybe even 16AWG. Especially because the expert modeler willing to solder his own leads (not crimp his own leads and connectors but solder them), this guy is a professional modeler intent on also eliminating about a foot of 22GA wire that's part of the servo itself. And like I mentioned earlier, it's OK to use the existing 22AWG for the control signal lead (yellow). This discussion is about heavier gauge for the power leads only. Anyway, do a neat job with heat shrink tubing after soldering and it'll look professional - and - the installation will carry much more current with less voltage drop. Win-win!

Inductance

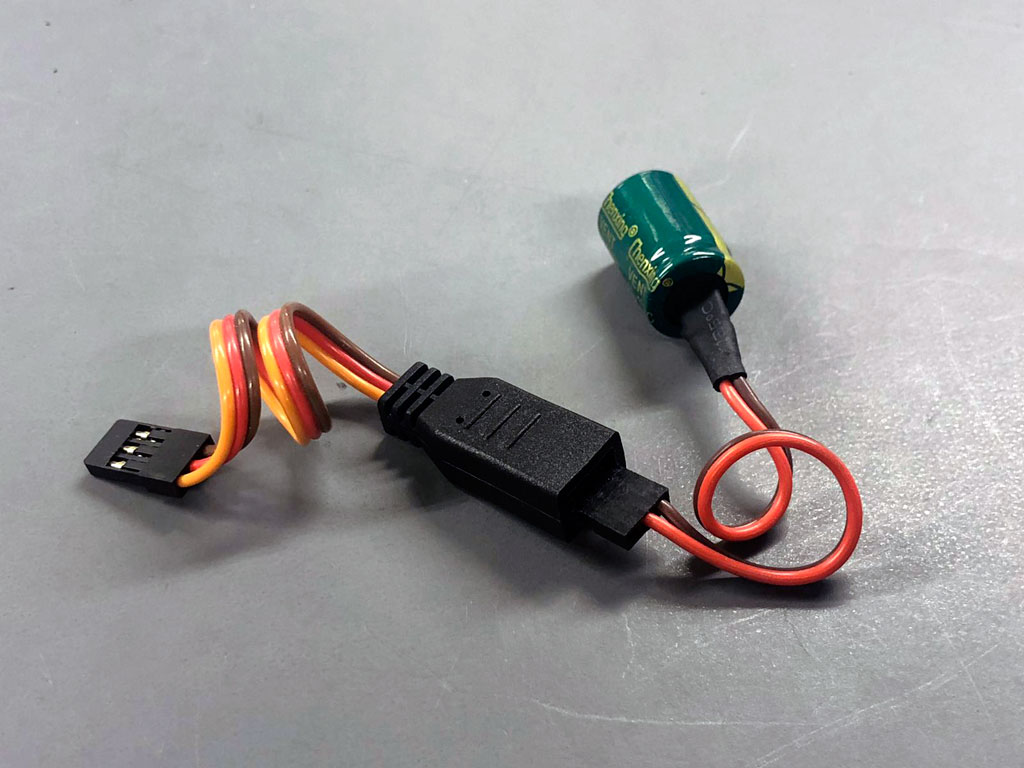

However, there's another issue to do with inductance when you extend servo leads with heavier gauge wire. It's admittedly a small effect but it's a fact, even with 20AWG extensions. So it's our opinion once you extend a servo beyond a 30" extension you should add capacitance to deal with the resistance and the inductance, too. How?

We make it easy as we offer a nice Y-harness and a low ESR capacitor on a lead. And remember, to deal with inductance, add the capacitance at the load, not at the receiver! Sometimes you add it at the receiver but for purposes of dealing with inductance, you want to add it at the load.

Our thinking is any time the extension exceeds 30" (meaning the total is actually ~40" (once we take into account an added 10-11" for the servo-lead), and since we're really completing a circuit, so we double this and it really means 80" of wire, then you're not only calculating voltage drop, we're adding capacitance to compensate for the added inductance due to the higher gauge wire!

Is this a defect in ProModeler servos? Nope, I'd advise you do the same with any brand of servos! This is an issue of fundamental physics, not a matter of opinion. Anyway, ours is a low ESR capacitor on a 4" twisted lead but if you're handy with a soldering iron, then it's just as easy to make up your own Y-harness with capacitors versus buying them from us. We share this because we're not in the capacitor or Y-harness business, we're in the servo business. Bits and bobs like the extensions, Y-harness, and capacitor exist on the site for the purpose of making your life easier.

Finally, there's another benefit of adding caps, which is it automatically delivers a jolt to aid the servo during low voltage situations (like when a lot of servos are busy doing their thing and depress the pack voltage). This is VERY important . . . and holds true regardless of servo brand. But is especially important with systems which are sensitive - this is no joke (Google 'Spektrum brownout' to learn more).

Anyway, hobby shops sell these capacitors as glitch busters. And by the way, it's not uncommon to be told to add a cap pack to the receiver, but that's for the purpose of brownout protection (for the receiver). And I'm explaining now why to do it at the load, meaning at the servo, instead of the receiver. We're fundamentally addressing the issue of inductance (due to heavier gauge extensions) with capacitance . . . and the twofer is the benefit of added juice for the servo under load when voltage sags.

Yes, this means sometimes you have a cap pack at the receiver and sometimes you use one at the load, too. So as usual, to the question of when do you use a capacitor? The answer is, it depends.

- If you're in doubt, just give us a call at 407-302-3361 and we'll help guide you.

Bottom line? Please believe me, if your experience base is with 4.8V servos and nobody has explained about making use of powerful high voltage servos, it's a totally different world and what worked before is no longer best practice. Heads up!