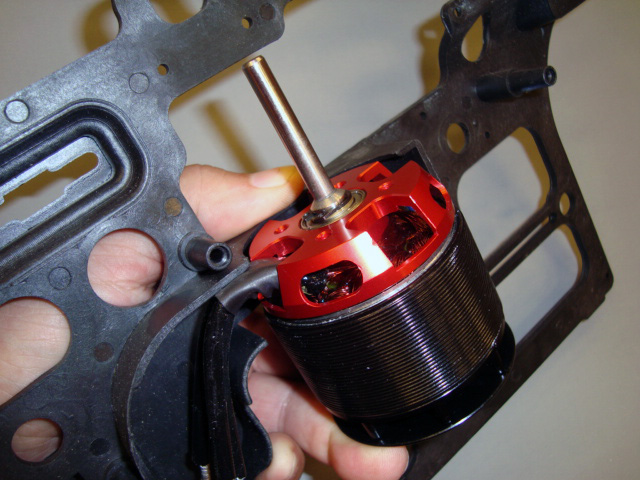

At ø58 x 58mm long, this massive motor is expressly configured with a ø6 x 42mm

long motor shaft (ø10mm internal) for 600/700-class model helicopters

and thus, isn't supplied with a fixed-wing prop-adapter or mounting

hardware. That said, these accessories are readily available, and this

motor is fantastic for airplane-use as well.

Unlike motors where a button-pusher monitors an automated winding machine loaded with multi-strand wire, this one is hand-wound with a single-strand (6-turns) of ø1.60mm

wire. This requires special tools and a skilled craftsman,

effectively making it a custom motor. Since winding the 12-tooth stator

by hand is finicky and time consuming work, this is a limited production

item so please call for availability.

Packing

the stator poles with thick wire is what gives this motor the ability

to handle a lot of current - e.g. perform a lot of work. After all, the

sole reason for using a single-strand is achieving maximum performance.

Anyway, depending on the

battery pack, this motor is well suited for scale, sport, hot-sport, and

extreme-3D maneuvers.

At 495g and capable of outputting 5000W (about 6.69

hp), what results is sufficient power reserve for pretty much any

maneuver you can imagine. By way of comparison, an OS MAX 1.05HZ-R

engine on 30% nitro makes about 3.75 hp. However, it weighs 596g and costs $530 (plus another $230 for the 185g muffler).

Finally, a suitable ESC (electronic speed control) will typically be of

120-200A capability, and due to the high specific power output, you'd be

well advised to lubricate the bearings (a wear item not covered by

warranty) each time you go to the flying field (a needle oiler makes

this quite easy - these are readily available at hobby shops that cater

to RC cars and trucks).

Too Long; Didn't Read (TL;DR)

This

is a seriously good motor because it makes monster power, has huge

bearings, and is hand wound with a single strand of wire. It's called a

Pmax because it's the maximum diameter motor, which you can comfortably

stuff into the

the side frames of a Pantera P6. However, it works pretty darn good with

a lot of 700-800 class helicopters plus fixed wing models (but you have to source your own prop adapter, which

is easy enough).

Background:

Physically

imposing and larger than the usual 4035-type motor, we've found it's

nearly Ideal when matched to the Pantera airframe by dint of it's

versatility. Especially when dynamically loaded with the Quattro rotor

head (4-blades) equipped with two sets of 700s because it has gobs of

torque. Moreover, if you subsequently mount the mechanics within a scale

fuselage, then you have the makings of a superb scale machine (or leave

it pod-n-boom for a hooligan's dream).

- A tight fit, at 58mm this is the maximum diameter motor that fits Pantera side frames

Available

in a range of Kv (450, 520, 630, and 720) this

is our top-of-the-range motor. We hope you delight in using it as much

as we do because within limits, it can almost be thought of as dial-a-motor.

For example, in a helicopter, once you select the basic rotor-head

RPM-range you desire, you can dial the power up or down via the cell

count and thus, totally change its personality. Dealing with just one variable

is nice! Anyway, here are some rule of thumb figures for main rotor

RPMs.

- 8S ~1300 RPM (scale use, 2 or 4-blade head)

- 10S ~1650-1925 RPM (sport, mild-3D)

- 12S ~2100-2250 RPM (extreme-3D)

Here's the math:

First,

let's take a 450Kv motor as an example; Kv is a constant that basically

means the motor output (RPMs) vary with voltage. In this case, 450Kv

means 1volt = 450 RPM (but technically,

Kv (lowercase v) is K=constant multiplied by v=velocity (as opposed to KV which is

Kilo Volts). Anyway, knowing the Kv is handy. In the case of the 450, it means on an

8-cell LiPo pack (nominally 29.6V) this motor

will theoretically turn about 13,320RPM (450x13,320). However, in

the real world it's results in something different.

Fudge factor: or why theory and practice differ

There's

some background math involved (quite a lot) but assessing an 85% fudge

factor will get you close enough for the real world with an

effective load. Note, some call this overall efficiency (the

combination between ESC efficiency, motor efficiency, and prop or rotor blade efficiency). We prefer to

use the term fudge factor because it's derived from our experience.

Anyway, as it turns out, 85% is a pretty valid

rule of thumb when loading the motor near it's max amp rating. Thus, 450Kv x 8cells x 3.7V/cell x 0.85(85% fudge factor)

=11,322RPM . . . and this is surprisingly close in the real world

regardless of whether you're using the rotor blades of a

helicopter, or a propeller, as the load.

Disclaimer:

By

the way, we know to be careful with throwing efficiency numbers around.

For example, the motor's efficiency isn't always what we say. If

we're overloading the motor e.g. beyond the proper current

range, then efficiency will be impaired. Similarly, running the motor

with reduced load, impairs efficiency as well. This last seems

utterly counterintuitive because

we expect heat when operating the motor with a load, and conventional

DC motors without a load don't get hot, but a brushless motor without a

load gets hot. What's with that?

Delving

into the subject leads you to learn it has to do with the magnetic field

changing

(inducing current into the iron)/. Thus, under low or no load

conditions you have a multitude of dead shorts hiding inside the center

of your motor! This has to do with the flow of current within the iron

laminations (in the stator core). The current is dissipating as energy (and thus,

producing heat). This is also known as eddy current or iron losses.

But the

point is, theoretical efficiency basically goes out the window in the real world so please just accept

the .85 fudge factor as something that will put you in the ballpark

with real world loaded RPMs. Hence, using a

fudge factor gives good practical results and this is important - especially recalling what a great wag once said on the subject:

Gear Ratios:

In a fixed wing application, e.g. direct drive, there's a 1:1 ratio between motor RPM and load (propeller) - e.g. the RPM of the prop - duh! However, with a helicopter, specifically a Pantera, the gear ratio is 8.7:1. Thus, for an 8S pack

11,322/8.7 = 1300RPM. This is nearly ideal for scale operations where the

goal is to simulate the 600-800RPM for the full scale machine more

closely than you can with a 2000RPM main rotor. By the way, with good throttle management this is good for maybe

8-9 minute flights.

450Kv on 10S

Now

take the same 450KV motor on 10S (37V). It's going to turn the main

rotor

at about 1625RPM, which as it happens, is hunky-dory for sport

aerobatics. So just by varying cell count we change the personality -

see what we mean by dial a motor? Anyway, as it happens, maneuvers like

loops, rolls, and stall

turns, plus flips and tumbles are the sweet spot for 1600-1650RPM range.

So basically, on 10S you get plenty

of poop for sport aerobatics. By the way, 'plenty of poop' is techno-speak

for approximating an OS 55-class nitro engine, e.g. just about the

perfect amount of power for a Pantera P6 model. This is enough to

effortlessly cruise around for up to 7-8 minutes on a

5000mAh pack. Believe it or not, this is plenty of air time for nearly

anybody. So the 450Kv motor on 10S is a very nice combination because you get

sweet performance at an affordable cost. What happens on 12S?

450Kv on 12S

Basically,

operating a Pantera P6 on 12S with a 450kv motor will really perk up

the performance (into the aggressive sport, or mild-3D range). The rotor

speed goes up to about 1925RPM but now the flight time decreases to

maybe 5-1/2 minutes.

Want to know what else the 450Kv motor is

great for? A classic pattern plane with an 11x7 prop (where you're going

to see abut 17,000RPM). You'll have a rocket ship on your hands. One

that will bellow like a bull and roar across the sky (and make every

head turn). Fun? Oh no . . . it's 'great' fun!

520Kv motor

So

what happens if you use the 520KV motor instead? On a 10S pack, with

the 8.7:1 gear ratio of a Pantera (or divide by the gear ratio of whatever helicopter you have in mind), this gives you about 1875RPM. This gives

sparkling aerobatic performance (and flight time goes

up a little bit, to maybe 6-1/2 minutes). Alternatively, stuff a 12S pack in there and

now you're going to see about 2250RPMs, which is what you want for crazy

3D performance range - not just tick-tocks but 'climbing' tick-tocks!

630Kv motor

You may also opt for the 630KV motor on 10S instead of a 12S pack. This will decrease

weight and with around 2275RPM the model will flip and roll so fast it's

a blur (note; 3D stick-bangers absolutely love this combination). Alternatively,

switch to an 8S pack and you're looking at 1825RPM, or sport performance again. Dial-a-motor! Anyway, this is plenty of RPM for sport aerobatics - plus - flight duration goes up to maybe

7-1/2 to 8 minutes. Perhaps this is more your cup of tea!

720Kv motor

What

about the 720Kv motor? Now the theory is 720RPM/volt but otherwise the

math is exactly the same. Thus, on an 8S pack it's 720x8x3.7x.85)/8.7 so

you'll see 2100RPM, which gives sparkling 3D performance. Depending on

the pack capacity and collective management you may see around 6

minutes.

However, if you opt for a 6S pack for this motor, then the rotor head is gonna drop to around

1560RPM. Now we're in the range of sporting maneuvers. E.g. a lot of hovering, cruising around, with the odd loop or roll thrown in. This is absolutely a perfect combination if you like relaxed loafing around for long duration flights (of

maybe 8-9 minutes, maybe more depending on how aggressive you are).

By the way, in

a fixed wing model, the 720Kv is nice on a 6S5000mAH pack because

you'll see 13,500RPM which is the sweet spot for a lot of 13x8-14x6

props.

Summary:

Astonishingly,

all this comes out of the same basic motor! The key is hand winding

different gauge wire. It's a stunningly simple system for making a

fantastic motor!

- One single piece of wire loops in and back out in an AabBCcaABbcC pattern

Mechanical details:

The rotor features Neodymium magnets (NdFeB) radially arrayed within the body. And

these strong rare earth magnets are secured within the rotor with high temperature

epoxy. Your goal is to operate it below 260°F. Exceeds the max of 350°F and it's gonna be toast. You've been warned.

Also, the rotor has been

dynamically balanced (to 30K RPM). This, by the way is the purpose of the blue

epoxy (balance weight) in the photo below. Anyway, all this hand-built care is what

you're paying for - the seamless and smooth delivery of pure power.

- Massive 10mm shaft - rotor is dynamically balanced

(blue epoxy) to 30K RPM

Anyway, packing

the 12-tooth stator with a single-strand of motor wire for high power handling, combined

with the best magnets, plus the effort of balancing the rotor for high RPMs

(so it won't buzz your electronics to death with vibration), along with 10mm

bearings and what results is a Pmax. You get with power delivery that's smooth as

silk, which is a really, really nice combination from this Delta-wound motor.

Bottom line? This motor is bad ass whether you're using it to power a helicopter or for fixed wing applications.